| Author |

Message |

Searcher

Senior Member

Username: searcher

Post Number: 473

Registered: 10-2004

| | Posted on Friday, April 22, 2011 - 09:25 pm: |

|

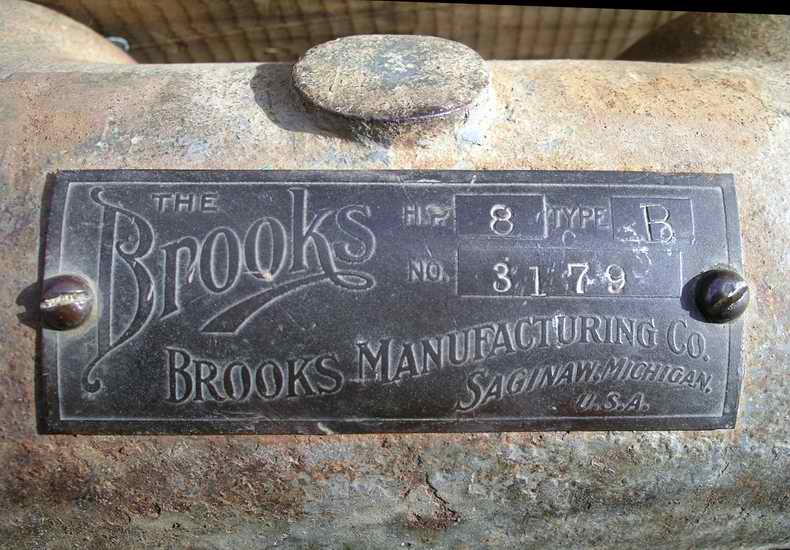

Hauled this home for a friend today. We assume the four hole flat bracket was for a gear driven mag. What brand and type were used on this engine? The timer is also missing. What brand and type should he be looking for?

Kind of neat to have both the Brooks and Caille tags on it. Is the serial number a Brooks number or is it a Caille number used by Brooks?

|

Searcher

Senior Member

Username: searcher

Post Number: 474

Registered: 10-2004

| | Posted on Saturday, April 23, 2011 - 04:18 pm: |

|

Here are a couple of photos of the timer/magneto drive shaft off the above engine. The top of the shaft doesn't look like it was cut off post manufacture but it seems short and there are no set screw marks on it, etc. Anyone familar with the type of timer this used?

Is a grease cup on the timer shaft original equipment or did somebody add it on later?

|

J.B. Castagnos

Senior Member

Username: jb_castagnos

Post Number: 582

Registered: 07-2002

| | Posted on Sunday, April 24, 2011 - 11:40 am: |

|

Looks like a nice find, not a lot of these around, never seen the mag option. With a mag it wouldn't use a timer. Just a guess, I think it probably used the Bosch mag like the Liberty twins. The one on the twins fired both towers at the same time on an opposed engine, yours would have to fire alternately. These mags rotated in a cradle mount to allow adjustable timing. |

J.B. Castagnos

Senior Member

Username: jb_castagnos

Post Number: 583

Registered: 07-2002

| | Posted on Sunday, April 24, 2011 - 06:00 pm: |

|

Here's a link to a mag.

http://caille.8m.com/catalogs/1922caille/20.htm |

Searcher

Senior Member

Username: searcher

Post Number: 475

Registered: 10-2004

| | Posted on Sunday, April 24, 2011 - 09:04 pm: |

|

J.B.,

Thanks for responding. It never occurred to me that this engine didn't need a timer. I only have one engine with a mag and it doesn't run so I have never really paid much attention as to how mags are hooked up. And thanks for sending the magneto link.

John Davis posted the attached photo of a Caille that was on eBay. That engine also has the bracket for a mag and it even has the gear guard for the gear that drives the mag. That engine has an elongated shaft that looks like it might have had a timer.

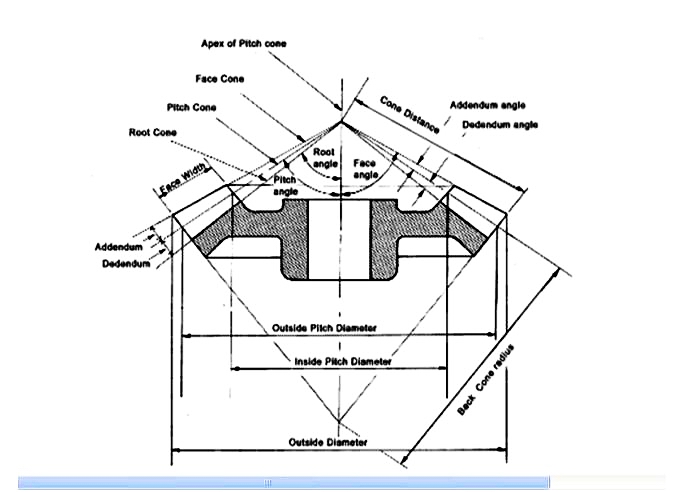

Since the mag is driven directly off the shaft with a gear, there must be a provision for adjusting the timing within the mag itself. Next question, is the gear on the mag the same size as the gear on the shaft. Hopefully, that bevel gear will prove to be a standard, off the shelf item.

|

J.B. Castagnos

Senior Member

Username: jb_castagnos

Post Number: 584

Registered: 07-2002

| | Posted on Monday, April 25, 2011 - 01:30 am: |

|

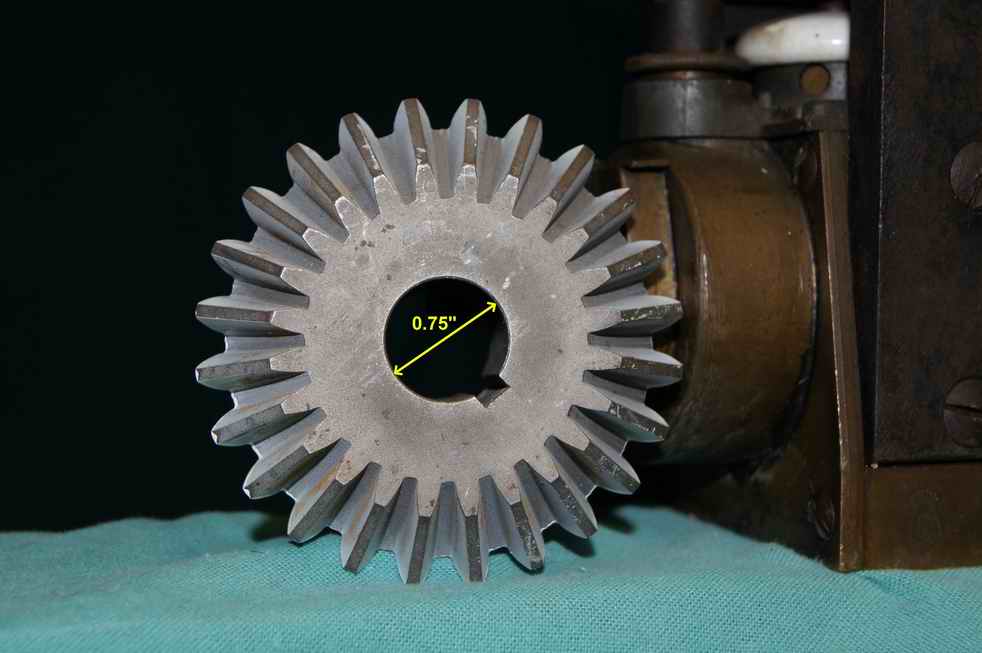

The mag has to be one to one, same gear on the shaft and mag. Is the mag drive gear the same as the lower gears? Caille used a gear one tooth different than a L-A, one has 25 teeth the other 26. I may have an old crankshaft gear, could be bushed and mounted to the mag. Count the drive gear and let me know. |

Searcher

Senior Member

Username: searcher

Post Number: 476

Registered: 10-2004

| | Posted on Monday, April 25, 2011 - 01:59 am: |

|

JB,

It figures - while the mag drive gear is the same as the lower 2 gears, all three have 24 teeth. Yup, and I counted each twice to be sure.

I appreciate your thoughtfulness. Thanks. |

J.B. Castagnos

Senior Member

Username: jb_castagnos

Post Number: 585

Registered: 07-2002

| | Posted on Monday, April 25, 2011 - 09:05 pm: |

|

I'll check the gears I have, the L-A drawings show 26 teeth. A friend once mismatched these, the engine started, died, cranked and cranked, started and died. It would slowly get in and out of time. |

Searcher

Senior Member

Username: searcher

Post Number: 478

Registered: 10-2004

| | Posted on Sunday, May 15, 2011 - 03:33 pm: |

|

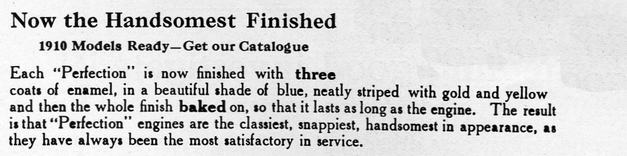

I tried to highlight the stripes painted on the Caille in this ad with only moderate success. But, they wouldn't have been visible otherwise. The text from the ad says the engine was neatly striped with gold and yellow and painted a beautiful shade of blue.

Has anyone seen one of these Caille's in original paint that could tell me which of the stripes were yellow and which were gold? How about the shade of blue?

|

John Davis

Senior Member

Username: johnny

Post Number: 389

Registered: 03-2006

| | Posted on Sunday, May 22, 2011 - 12:33 am: |

|

Seacher, can you post a photo of the other side of the engine?

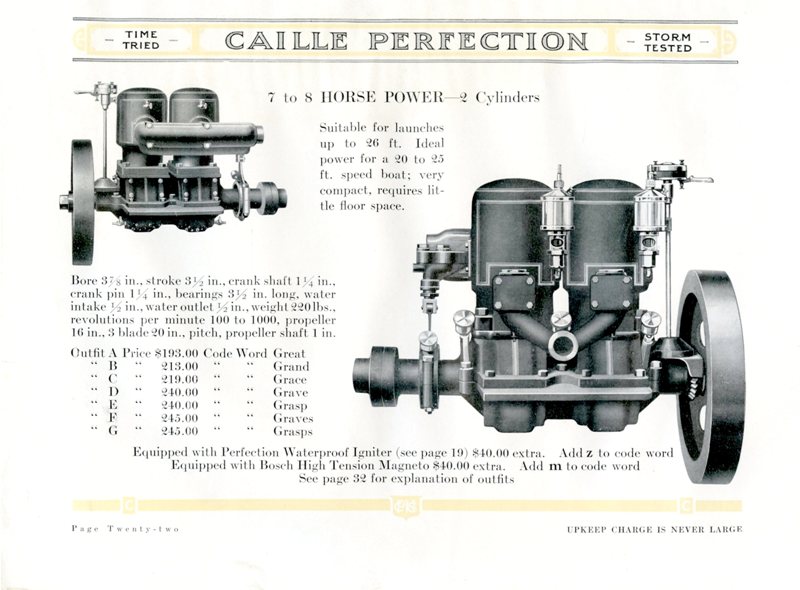

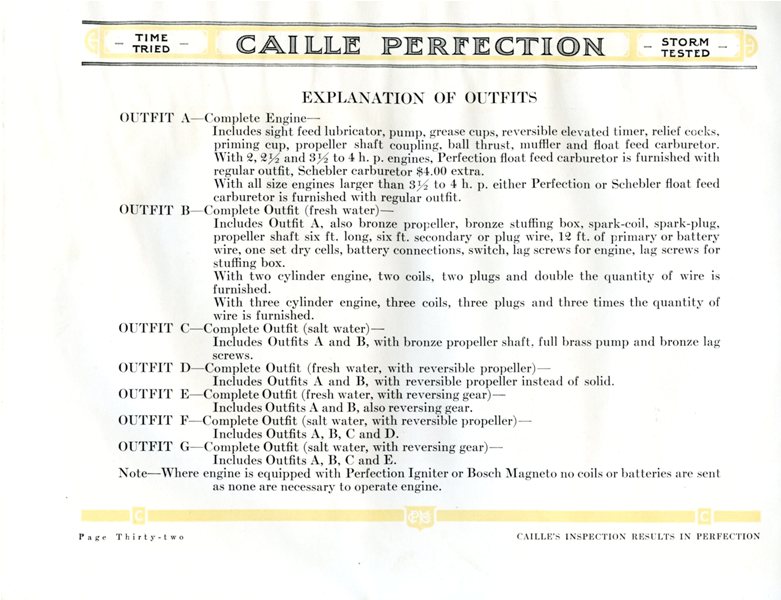

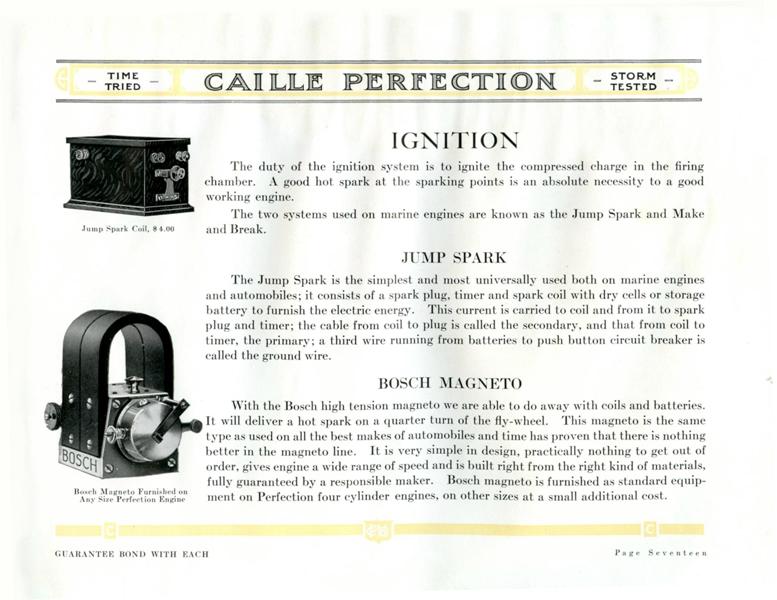

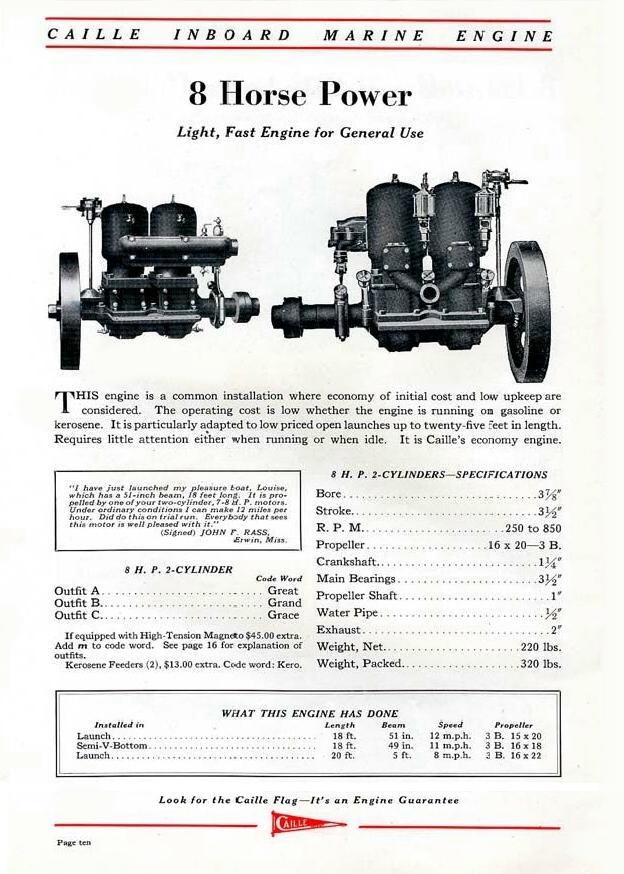

Below are scans of a 1911-12 Caille Perfection Twin very close to yours. However it does not show the Bosch magneto option but it talks about it. The bosch magneto was just like the ones used on automobiles. Ignitor was also a option on this model. Low tension magneto used for ignitor, high tension magneto for spark plug. Your engine is a type "B" fresh water equipped engine. I believe the photo of the blue Caille Twin is a earlier model probably 1908-1909. Two different style exhaust. I will post a scan of the magneto.

|

John Davis

Senior Member

Username: johnny

Post Number: 390

Registered: 03-2006

| | Posted on Sunday, May 22, 2011 - 01:33 am: |

|

It appears that Brooks manufacturing Company made and sold gramophones "Record Players". The company probably was a jobber on the side like a lot of companies back in the day. Unless there were two Brooks Manufacturing companies with the same name in the same town around the same time. |

John Davis

Senior Member

Username: johnny

Post Number: 391

Registered: 03-2006

| | Posted on Sunday, May 22, 2011 - 10:21 am: |

|

Scan of high tension Bosch magneto for spark plug engine.

|

John Davis

Senior Member

Username: johnny

Post Number: 392

Registered: 03-2006

| | Posted on Sunday, May 22, 2011 - 10:57 am: |

|

Hugh,

Here is a scan of the 1922 Caille Twin 8hp.

|

RichardDurgee

Senior Member

Username: richarddurgee

Post Number: 2639

Registered: 11-2001

| | Posted on Sunday, May 22, 2011 - 11:51 am: |

|

*

Brooks Boat Manufacturing Co. Bought their engs from other mfgrs and put their tags on them. Dubrie and caille were two that come to mind.

Engine tags with Saginaw address are 1909 or later, 1908 back to 1901 have the Bay City address !

1906 ad

* |

John Davis

Senior Member

Username: johnny

Post Number: 393

Registered: 03-2006

| | Posted on Wednesday, May 25, 2011 - 06:23 am: |

|

JB, Magneto probably turning 2:1 ? Twice as fast as the crankshaft? Then the magneto would be firing ever revolution to itself, but yet firing twice to every revolution of the crankshaft at a 180 degrees apart? |

John Davis

Senior Member

Username: johnny

Post Number: 394

Registered: 03-2006

| | Posted on Wednesday, May 25, 2011 - 09:41 am: |

|

Unless the magneto is made to fire every 180 degrees and the gear ratio is 1 to 1. The gears are all the same size so it should be 1 to 1?

I believe my Caille twin has a 1 to 1 ratio but it uses a timer (no mag) with two contacts with in the timer that are 180 degrees apart.

If this is the case then would the magneto be made just for a twin cylinder application? |

J.B. Castagnos

Senior Member

Username: jb_castagnos

Post Number: 596

Registered: 07-2002

| | Posted on Wednesday, May 25, 2011 - 11:35 pm: |

|

John, on the opposed engines the mag fires both cylinders at one time, the coil is open and each end hooks to a tower, The spark comes out of one end of the coil, goes through one plug, the block, the next plug, and returns to the coil. These fire once every revolution. On the inline twins firing 180 apart, the mag fires twice every revoution, it has a rotor that distributes the fire to alternate towers, firing only one at a time. |

John Davis

Senior Member

Username: johnny

Post Number: 395

Registered: 03-2006

| | Posted on Thursday, May 26, 2011 - 06:21 am: |

|

"On the inline twins firing 180 apart, the mag fires twice every revolution, it has a rotor that distributes the fire to alternate towers, firing only one at a time"

So the gear ratio on the Caille is 1 to 1 correct? I have never used a magneto on a inline twin two cycle. Not much experience for me with the two cylinder magnetos.

I have my two twin cylinder engines wired up with two buzz coils. I originally was going to use one buzz coil but I thought it might get a little to hot working twice as hard. The model T's used a buzz coil for each cylinder so that is why I decide to use two buzz coils one for each cylinder. I think if I used one buzz coil it would be firing both spark plugs at the same time every 180 degrees of rotation. Not sure that would work very well? |

Searcher

Senior Member

Username: searcher

Post Number: 507

Registered: 10-2004

| | Posted on Wednesday, December 14, 2011 - 11:44 am: |

|

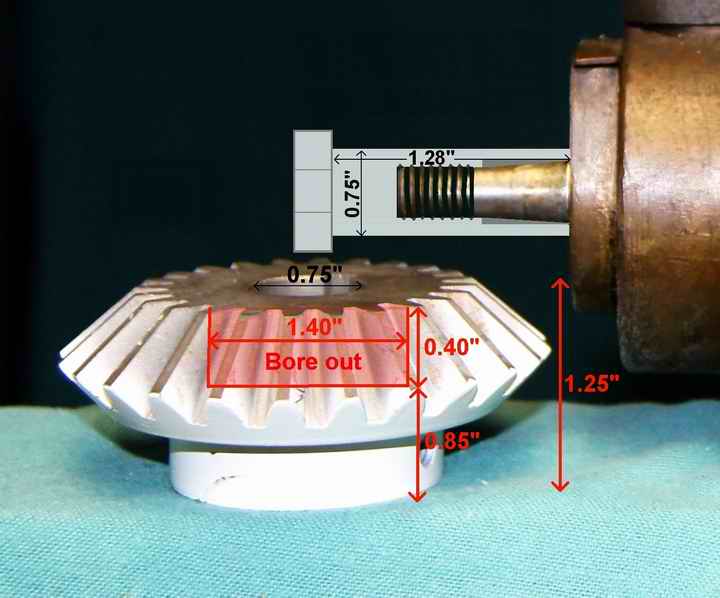

I finally found a 24 tooth gear of the right dimensions for the magneto. It is a new Boston Gear bought for $26 on eBay and it is a perfect match. I didn't realize how many measurements went into describing a gear!

Now the question is how to fit the gear to the magneto shaft. The gear is too thick and the bore too large. I sketched out two possibilities, one adapting the shaft to the gear, the other adapting the gear to the shaft. Not knowing anything about machine work, the best solution to me is to bore out the gear as shown to accomodate the nut on the end of the magneto shaft (plus the thickness of a standard socket) and then to sleeve the remaining bore and machine it to the taper of the shaft. I do not know how one machines a taper. Am I on the right track or have I drifted into Rube Goldberg territory?

|

Ernie

Senior Member

Username: ernie

Post Number: 1459

Registered: 01-2002

| | Posted on Wednesday, December 14, 2011 - 02:15 pm: |

|

Just bore out the face of the gear and with proper machining you can put a sleeve in the gear. With a proper shrink fit and a set screw it will not move. I have done it several times and it worked well.

You can cut the taper using the compound on your lathe carrige since it is only an inch or so long. JB can most likely describe the process better or have a better idea.

Hope this helps

Ernie |

Searcher

Senior Member

Username: searcher

Post Number: 508

Registered: 10-2004

| | Posted on Wednesday, December 14, 2011 - 08:09 pm: |

|

Ernie,

Thanks for responding. I know nothing about machining. I will have to read up on using the compound on the lathe carriage to do a taper. I bought an early 1940's 9" South Bend lathe some time ago to learn on but paying work has gotten in the way of setting it up. So, I hope to learn enough on this site about what should be done to make this gear work so that I can convey that information to a self taught hobby machinist friend.

When you say shrink fit, I assume the gear is heated prior to inserting the sleeve. How hot should the gear be? If the bore of the gear is exactly 0.75", should the diameter of the sleeve be 0.75" as well or a thousanth or two oversize? |

John Davis

Senior Member

Username: johnny

Post Number: 430

Registered: 03-2006

| | Posted on Wednesday, December 14, 2011 - 09:49 pm: |

|

Five tenths (.0005) press fit is fine and use high temp loctite. Make sure you clean both contact surfaces real good with lacquer thinner or acetone before applying the loctite. The press fit a long with the Loctite will keep the sleeve from slipping & turning. No heat needed. Machine the tapper after you have pressed the sleeve in.

Have you thought about putting a timer back on the engine? If you use the magneto you will not be able to retard or advance the timing for speed control and you will have to depend on carbs throttle control. Unless your magneto has some kind of advance & retard control on it? |

Searcher

Senior Member

Username: searcher

Post Number: 509

Registered: 10-2004

| | Posted on Wednesday, December 14, 2011 - 10:10 pm: |

|

John,

Thanks for the advice. It is all very helpful to me. Neither you or Ernie mentioned cutting a keyway into the sleeve. It sounds like a keyway isn't needed which is great.

I know little about magnetos other than a few bits and pieces about a couple of the Bosch models. The Bosch DU series, Models 5 and 6, have advance and retard built right into the magneto and it is controlled by a little lever on the magneto. I would like to find a Bosch DU2 Model 5 or Model 6 but they aren't very common and are in high demand. The DU4 magnetos are fairly common so I bought a DU4 Model 5 and that is what I will use on the Caille. |

J.B. Castagnos

Senior Member

Username: jb_castagnos

Post Number: 635

Registered: 07-2002

| | Posted on Wednesday, December 14, 2011 - 11:38 pm: |

|

If you can mount the mag between centers in the lathe you can put a dial indicator in the tool holder, set the compound at the approximate angle, feed in and out with the indicator riding on the back side of the shaft. Adjust the compound until the indicator stays zero. Remove the mag, set the gear up with the teeth facing the chuck, large side of the hole will be on the outside. Bore by turning the compound in and out, increase bore diameter with the cross feed. It should have a key, do you have a broach set? You can key it while it's still in the lathe using the compound, need to make a tool that scrapes as you feed in and out, takes a while but it can be done. |

Searcher

Senior Member

Username: searcher

Post Number: 510

Registered: 10-2004

| | Posted on Thursday, December 15, 2011 - 01:02 am: |

|

JB,

I am not clear on this at all. However, when I get back in the office on Saturday, I will try to make a mock up of what I think you are talking about.

The gear already has a keyway. The insert will need a corresponding keyway. Cutting a keyway on the outside of the insert strikes me as a lot easier to do than cutting one inside the bore of the gear. I have two South Bend milling attachments that came with the lathe so I may try to figure out how to cut a keyway in the insert myself. As to the broach set, I wouldn't know one if I dropped it on my foot. I need to find a good lathe manual.

Thanks JB.

|

J.B. Castagnos

Senior Member

Username: jb_castagnos

Post Number: 636

Registered: 07-2002

| | Posted on Thursday, December 15, 2011 - 06:24 am: |

|

I was reffering to the keyway on the inside of the taper. Cutting a keyway in a tapered hole is a little more difficult, that's why I suggested using the compound of the lathe and scraping it in. A brass bushing would be easier to work with. The key on the outside isn't necessary if you're press fitting with Loctite. |

John Davis

Senior Member

Username: johnny

Post Number: 431

Registered: 03-2006

| | Posted on Thursday, December 15, 2011 - 07:57 am: |

|

J.B. is correct you will still need to put a keyway on the inner tapered diameter of the sleeve you make and press in. You will cut away the existing keyway on the inner diameter of the gear when you bore a straight hole for the sleeve. So the straight hole in the gear will be larger then .750 what ever it takes to cut away the keyway. If you make your sleeve about a 1/2 inch longer then the thickness of the gear it will give you something to chuck on when turning the taper on the opposite side. Once you finish the taper and the keyway flip the part around and machine off the extra length on the sleeve and do your counterbore.

When you go to bore the hole in the gear for the sleeve you will have to chuck on the OD where the set screw is located. Make sure you indicate the tapered hole to see if it is concentric to the diameter you are chucked on. I would wait and machine the counter bore in the gear after you get the sleeve pressed in and the taper machined.

JB has been doing machining for a long time and might have a better way. |

John Davis

Senior Member

Username: johnny

Post Number: 435

Registered: 03-2006

| | Posted on Monday, January 23, 2012 - 07:29 am: |

|

Hugh, did you get the magneto gear to work on your Caille twin?

I just picked up another Caille twin at the Florida Flywheeler show this past week. I'll post some photos soon. The engine does not have a magneto on it and it is smaller size then the one I have. Must be the 8hp twin Caille. Looks just like your twin but with no brass name tag. The inspection covers are embossed like yours. |

Searcher

Senior Member

Username: searcher

Post Number: 516

Registered: 10-2004

| | Posted on Monday, January 23, 2012 - 09:55 am: |

|

I have not done anything with the Caille yet. I am greatful for the help I got on the Caille, from you and others, and especially in a call from JB (thanks JB).

The Caille and most everything else iron got pushed into the corners after December 22. On December 20, Doug K. sent me photos of that big old Knox, on December 21 the Knox was mine, and on December 22 I started rearranging the place to make room for it. Love at first sight!! |

John Davis

Senior Member

Username: johnny

Post Number: 436

Registered: 03-2006

| | Posted on Wednesday, January 25, 2012 - 11:01 am: |

|

Sounds like you got the engine fever just as bad as I do. |

Bruce Hall

Senior Member

Username: bruce

Post Number: 290

Registered: 07-2002

| | Posted on Thursday, January 26, 2012 - 10:19 am: |

|

John. pictures of your recent Caille Twin find in Fl.?? |

John Davis

Senior Member

Username: johnny

Post Number: 437

Registered: 03-2006

| | Posted on Thursday, January 26, 2012 - 08:04 pm: |

|

I just shot these photos tonight in the dark. Have not even unloaded my trailer from the show. Engine still in the back of my gator. Caille Twin 6-8 hp?. It's a little smaller engine then my 12 hp Caille twin and I think it might be a little later model also. Has real good compression. Timer needs a little work. I removed the inspection covers and the exhaust manifolds and peaked in. Appears to have not been run in the salt water and fairly clean inside. Anyone have any spare parts for the timer they would be willing to part with for a price?

|

William Schaller

Senior Member

Username: billschaller

Post Number: 474

Registered: 12-2003

| | Posted on Thursday, January 26, 2012 - 09:21 pm: |

|

John,

I think your "Chunk O'Wood" brand timer looks better than my "Glow-in-the-Dark Polystyrene" brand timer.

|

John Davis

Senior Member

Username: johnny

Post Number: 438

Registered: 03-2006

| | Posted on Friday, January 27, 2012 - 09:02 am: |

|

Yea the timer is of fine 2x4 design & construction probably after market, way after! I think it may have a some termite damage.

Anyone have photos of a complete timer like this one on my Caille twin without the fine wood modifications? Photos of the inside & outside would really help. |

John Davis

Senior Member

Username: johnny

Post Number: 439

Registered: 03-2006

| | Posted on Friday, January 27, 2012 - 01:14 pm: |

|

Bruce,

Do you have Caille engines?

Bill,

What brand is the twin engine you posted?

|

William Schaller

Senior Member

Username: billschaller

Post Number: 476

Registered: 12-2003

| | Posted on Friday, January 27, 2012 - 01:21 pm: |

|

Stroud.

http://www.oldmarineengine.com/discus/messages/2/252394.html |