| Author |

Message |

Rich Burdick

New member

Username: richbu

Post Number: 1

Registered: 11-2011

| | Posted on Sunday, November 20, 2011 - 10:42 pm: |

|

HI,

I have a Gray 6hp engine that was used to run a wood mill in Northern California. It has been in a barn for many years. The serial # stamped in the block is 16R9611. It has a keyed shaft. It looks like most, if not all, the parts are here.

I just started cleaning it up so I could read the name plate and see just how rusty things are. I plan to take all the brass items off the block and then water blast the iron to clean it up prior to trying to get it to turn.

Any suggestions or tips I should know about before I do something I'll regret? Thanks     |

chris johnson

New member

Username: chris_johnson

Post Number: 3

Registered: 04-2009

| | Posted on Monday, November 21, 2011 - 11:13 am: |

|

looks like a neat engine I have not seen a gray R with 2 flywheels I have a 4 hp gray R but only one flywheel a little howes marvel oil down the spark plug hole would help let it soak looks like a great project |

Jim Parrott

Member

Username: jim_parrott

Post Number: 28

Registered: 06-2009

| | Posted on Monday, November 21, 2011 - 05:49 pm: |

|

Rich,

That is a nice find. I would leave it assembled as to not disturb the patina. Ensure grease and oil passages are clear not forgetting the slinger ring which lubes the connecting rod and crankpin. Lube it up and fix whats needed and let it run. It wouldn't hurt to run premix oil and gas in it either.

JIm |

William Schaller

Senior Member

Username: billschaller

Post Number: 456

Registered: 12-2003

| | Posted on Monday, November 21, 2011 - 07:34 pm: |

|

Rich,

can you send me big pictures of it. My 10 hp stationary was already restored by the time I got it.

|

Rich Burdick

New member

Username: richbu

Post Number: 2

Registered: 11-2011

| | Posted on Tuesday, November 22, 2011 - 12:35 am: |

|

Chris, Jim and William,

Thanks for the info. I have alot to learn, it looks like I'll be spending time on this message board reading posts and learning all the vocabulary.

Chris, I haven't seen a Gray with 2 flywheels either. I wonder if they are to generate more torque for running the mill?

Jim, How does one clear all the grease and oil passages... solvent?

William, I'll take it outside tomorrow and get some better pictures in the sunlight and e-mail them to you.

Thanks again! |

William Schaller

Senior Member

Username: billschaller

Post Number: 457

Registered: 12-2003

| | Posted on Tuesday, November 22, 2011 - 01:53 am: |

|

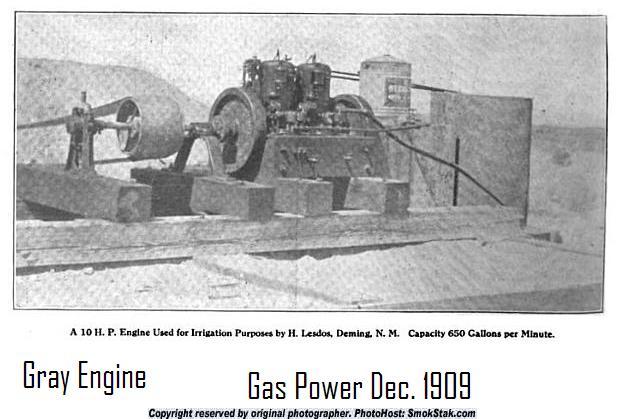

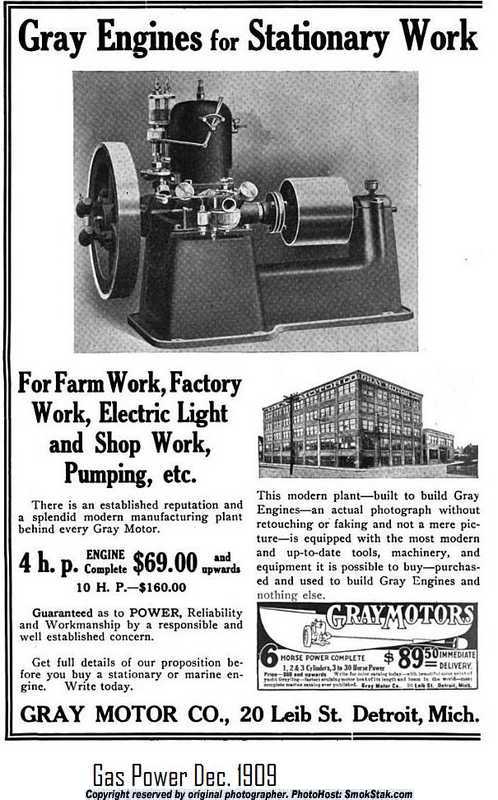

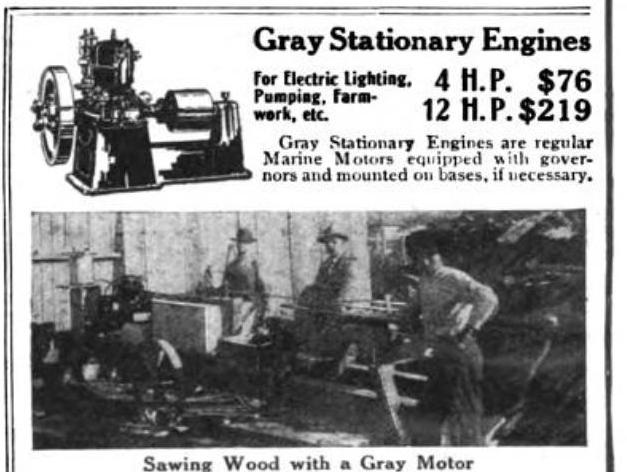

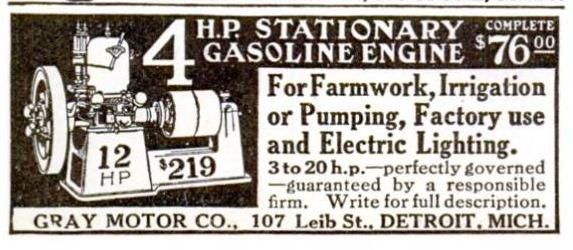

some ads

|

William Schaller

Senior Member

Username: billschaller

Post Number: 458

Registered: 12-2003

| | Posted on Tuesday, November 22, 2011 - 02:03 am: |

|

more

|

Jim Parrott

Member

Username: jim_parrott

Post Number: 29

Registered: 06-2009

| | Posted on Tuesday, November 22, 2011 - 07:42 am: |

|

Rich,

Assuming the engine isn't frozen. If grease in cups are dried up, remove cups and extensions, clean with solvent and blow out with air. Clean out passage to main bearing with a pick. New grease and heat from running should force out the rest of the old grease. Disconnect the oil lines at the engine, open the valves to check for flow, clean out lines and oilers if needed. Open the inspection port in the crankcase (big threaded plug) look inside slinger ring with mirror for scale, if clean turn engine til crankpin is down try to force lubricant thru passage and see if it comes out by crankpin and connecting rod. I think a syringe and plastic tube should work well for this, will try it on my 6HP S and post a pic for you. This passage is important as I have heard of bad things happening if clogged.

Jim |

Jim Parrott

Member

Username: jim_parrott

Post Number: 30

Registered: 06-2009

| | Posted on Tuesday, November 22, 2011 - 08:38 pm: |

|

Rich,

Checked my engine this evening, the slinger ring was clean, it was hard to see but I could see the the oil passage going thru the crank pin. I tried sticking a tube in the hole but was hard to do in the little time I had today. Instead I squirted oil and gas mixture into the slinger ring with the crankpin in the lowest position, and it was obvious that it passed thru the pin and leaked out the bearing. Be careful to squirt a little at a time or you will over flow the ring and will wet everything. On yours you could just let the oiler do this for you. If you suspect a clog, you may be able to clear by removing cylinder & connecting rod and cleaning out the passage from the crank pin.

I think on my engine I am going to pull the cylinder, piston, & rod, and drill the connecting rod as on premix engines. I will run premix and a little oil as well.

Hope this helps,

Jim

|

Rich Burdick

New member

Username: richbu

Post Number: 3

Registered: 11-2011

| | Posted on Wednesday, November 23, 2011 - 07:01 pm: |

|

Thanks Bill and Jim, I'm looking forward to getting into this over the winter and see if i can make it run. I'm sure I'll be back with many more questions.

Rich |

Rich Burdick

Member

Username: richbu

Post Number: 4

Registered: 11-2011

| | Posted on Saturday, March 22, 2014 - 06:13 pm: |

|

Hi I'm selling my Gray Engine and the Mill it ran for all those years. Fun restoration project for someone with more time and expertise that I have.

Asking $750 for The engine and all the mill parts.

|