|

| Palmer Make and Break Firing Pin info |

| Author |

Message |

Ernie

Senior Member

Username: ernie

Post Number: 1389

Registered: 01-2002

| | Posted on Tuesday, August 02, 2011 - 08:06 am: |

|

From Dick Day

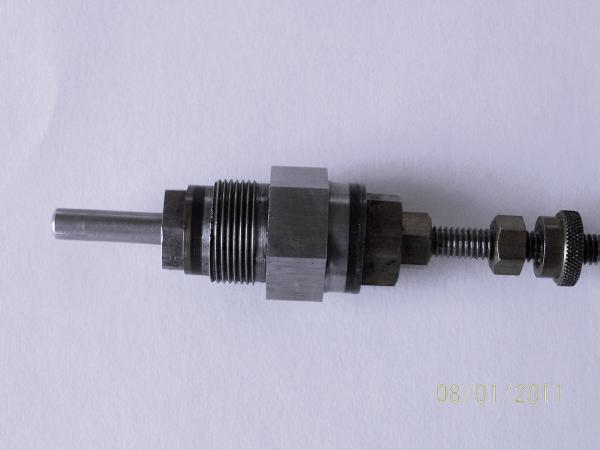

Firing plug from Palmer Bros. Nickel firing pin.

Notes on firing plugs for Make /Break marine engines 08-01-2011 By R. A. Day Jr.

It should be noted that there were a number of makers of the early make and break firing plugs and while some are marked by their makers others are not. Keep in mind the following dimensions are taken from a NOS Palmer Bros. firing plug and therefore these dimensions do not necessarily apply to other makers products. The most important dimension is the firing pin bushing and the thread size. This is comparable to the thread size on a spark plug. Firing plugs are getting very hard to find so hang on to those you have and rebuild them for new acquisitions. For Palmer Bros. Firing Plugs the thread dia. is 1" and 18 threads per inch. Other makes of plugs may be used if this critical dimension is met. However one needs to insure that the clearances for the firing pin and Sparker spindle will be appropriate when installed in the cylinder or head.

Plugs are found with brass or steel firing pins and they seem to work as well as the nickel pins. It is believed the nickel rods eroded less under the influence of the arc formed at the moment of "Break". They were less liable to weld to the sparker spindle at the moment of "Make". The firing pin is not threaded the full length and the factory finished bottom end has an approximately 9/32" radius, not a pointed end. It is suggested the reason the Firing pin was not threaded full length was to preserve as much nickel as possible over the life cycle of the Firing Pin. The end radius is probably to reduce the erosion and likelihood of a point welding the end to the Sparker spindle. Worn firing pins are typically found with the ends shortened and showing evidence of high temperature melting. The brass ends often are quite deformed from the original 5/16" dia. They work very well in this condition and should not be discarded as they are fully functional in many cases. The precise factory radius on the end is probably of no real significance being more a matter of avoiding a square or pointed end in the manufacturing process.

The overall length of a new firing pin is approx. 5-1/4". It is threaded 5/16' 18 THD. The lower end of the firing pin is not threaded back 1-3/4" from the end radius. This gives a full diameter nickel reserve as the firing pin erodes.

The Firing Pin bushing is steel (Some are found in brass) approximately 1-1/8" across the hex flats. This part is often found with only two flats. Either works well.

The Firing Pin shown is configured with a hex head nut and knurled wing nut. This is only one of commonly found configurations. In one configuration the top of the Firing Pin is found with two flats milled to permit about a ¼" wrench to rotate the firing pin when the brass Firing pin lock nut at the top of the firing plug is loosened. This allows shifting the position of the firing pin without removing the firing plug from the cylinder.

Another configuration uses a knurled brass nut with an approximately 1/16" dia hole through the Firing pin approximately 1/4" from the top. The purpose of the hole is to permit the wire from the coil to be inserted in the hole with either a wing nut or knurled nut located below the wire and then raised until it pinches the wire in the firing pin. This configuration keeps the wing or knurled nut from being lost in the bilge in the event it becomes loose.

Nickel is somewhat magnetic so don't mix it up with zinc plated steel "All Thread" and then think you can use a magnet to find it. Nickel rod is very expensive. I don’t know if it can be purchased threaded 5/16” 18Thd in small amounts.

|

|

|

|

|