| Author |

Message |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2212

Registered: 11-2001

| | Posted on Wednesday, October 14, 2009 - 07:13 am: |

|

*

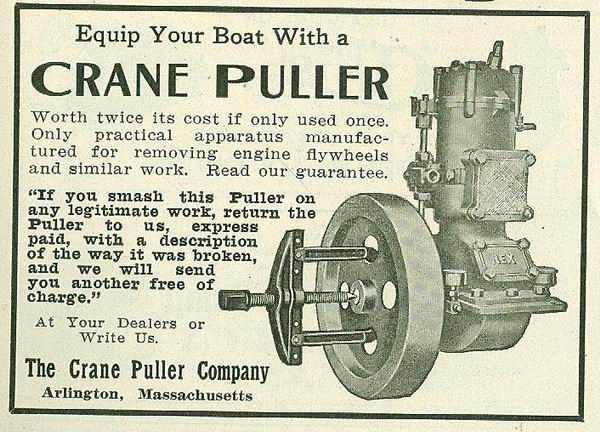

"Pullin on the Rex" 1915

** |

ernie

Senior Member

Username: ernie

Post Number: 1072

Registered: 01-2002

| | Posted on Wednesday, October 14, 2009 - 09:23 am: |

|

Looks like a good way to break a flywheel to me.

Pulling that far from the center on an unreinforced area is sure to make little parts out of big ones |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 483

Registered: 07-2002

| | Posted on Thursday, October 15, 2009 - 07:50 pm: |

|

If I smash this puller, where do I send it for replacement? That's an 8" wrench for relative size.  |

kerrigan

Advanced Member

Username: kerrigan

Post Number: 31

Registered: 06-2008

| | Posted on Thursday, October 15, 2009 - 08:18 pm: |

|

Ernie:

What tool would you use to pull that flywheel? One with 4 claws instead of 2? |

richardday

Senior Member

Username: richardday

Post Number: 820

Registered: 11-2003

| | Posted on Friday, October 16, 2009 - 09:10 am: |

|

Myself I would not try to pull a spoked flywheel which is rusted to the crank. Make up two inch thick steel plates about a foot square. Bore a clearing hole in the center just clearing the crankshaft diameter. Saw clearing width slots to the center hole but save the pieces. Mount the crankshaft in the press with the two plates so when putting the cut out piece in the top plate just under the flywheel it fills in the gap in the top plate. Cut a couple of pieces of sheet lead with a hole the size of the crankshaft. Slit the sheets of lead so they can fit around the crankshaft. Arrange the slits at 180 degrees. The purpose of the lead sheets is to insure no small high spots can in the flywheel hub will cause the pressure to possibly crack the hub.

Using this approach I have suceeded removing badly stuck flyweels with no breakage. Guess there will always be a first time. I never use heat on the hub to expand the hub. Afraid I might set up stresses in the spokes etc. which could be disastrous. |

ernie

Senior Member

Username: ernie

Post Number: 1079

Registered: 01-2002

| | Posted on Friday, October 16, 2009 - 09:29 am: |

|

I usually don't pull them. As Dick says I use the press. On a Palmer BH I drilled 2 3/8 holes near the hub and made backup plates to go on the back to make sure I didn't break anything using a puller. |

kerrigan

Advanced Member

Username: kerrigan

Post Number: 32

Registered: 06-2008

| | Posted on Friday, October 16, 2009 - 10:20 am: |

|

Thanks fellows. My questions were academic. I can't imagine anyone wanting or needing to pull a flywheel while adrift as implied in the Crane Puller ad. My Palmer BH has two tapped holes through the flywheel near the hub but very little space behind the flywheel to insert anything. The need to remove flywheels seems remote anyway. I have several pullers of different sizes and configurations. They are mighty handy tools. I haven't smashed one yet. |

billschaller

Senior Member

Username: billschaller

Post Number: 303

Registered: 12-2003

| | Posted on Friday, October 16, 2009 - 03:32 pm: |

|

I am sure it is much easier to pull a 5 year old flywheel off an engine than a 105 year old flywheel. And, I bet the boat market was a small part of their business, after all, a good farm engine has twice as many flywheels to pull. |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2229

Registered: 11-2001

| | Posted on Friday, October 23, 2009 - 01:58 pm: |

|

*

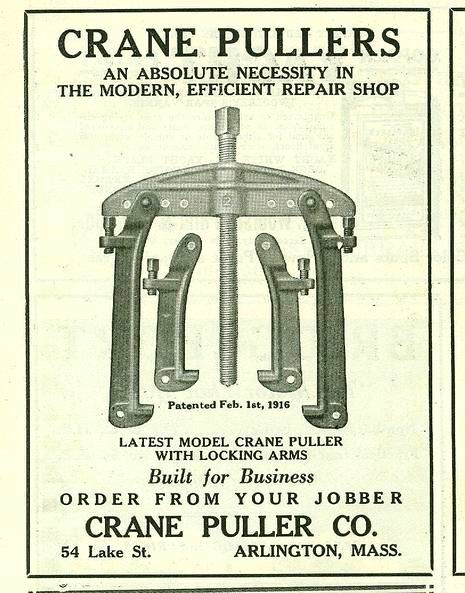

Boat magazine ad 1919

** |