| Author |

Message |

bobz1

New member

Username: bobz1

Post Number: 1

Registered: 03-2009

| | Posted on Thursday, April 23, 2009 - 09:40 am: |

|

Looking for anyone who has experience on the proper operation of a 1907 two stroke 4 cylinder rochester engine. I am a restorer of engines , and this is the first two stroke project i'v ever taken on.I plan on keeping the cast iron pistons .This engine has oilers going to the crankcase but did they also mix oil with the gas. If there's anyone out there who's an expert on these engines , please i'd like to talk to you on the phone. thanks

|

steve_fox

New member

Username: steve_fox

Post Number: 3

Registered: 01-2009

| | Posted on Sunday, April 26, 2009 - 08:46 pm: |

|

Dear Bobz1

I am not an expert on running these engines, however, I have some knowledge. Perhaps this can be of help.

So you got that one. Good on you. I looked at it once, but had enough projects. Already have a 4 cylinder 35-50 hp Erd 2 stroke from 1910 and several 3 cyl racers from the same era.

Here are several maybe obvious, maybe new points to ponder:

I have a Rochester motor catalog for this period showing this engine. Where it is,I do not know so I am going from memory at this point.

1) In the pictures I saw, I didn't see a timer. Did you take it off? If you look in the picture above, there should be (can't think of the technical term) a small box or mount holding perpendicular gears at the end of the side shaft past the aluminum bracket. There was a vertical shaft leading to a timer or distributor-can't recall exactly, but if you don't have one you have some (a lot) of reconstruction work to do.

also where is the second gear for the timing and waterpump shaft? You do have it I presume. It was shown in the picture I saw. I don't see in your picture is it obscured by the lever?

2)At the time they did not mix oil and gas, but all of these engines work best that way now. The glass oilers are really for show at this point unless you a real fanatic- I wouldn't risk an engine on this method at any rate. The crankshaft greasers are a must and have to be turned down at intervals while running the engine, although these appear to be spring loaded jobs. Mix at 20:1 although there are more knowlegeable heads in this site for more certainty on this.

It is missing the middle greaser where someone put the lifting bolt. (look on Ebay guaranteed)

3) If it turns over easily and has bounce, you're 80% of the way there. If not, you know the drill, take her all apart and clean it up, replace any broken rings, tighten up the piston rod big end if needed. These engines were hot rod engines of their day and didn't see much use as they were too scary and complicated for the average Joe boater to start and run. This was strict a racer's toy. The good news is that there should be little wear and tear, however, the missing spark plugs look worrisome- is it stuck?

4) Be careful taking off cylinders as there are fiber spacers between them which seal hole adjacent the crankcase.

Phone is 1-613-774-6847 after 8pm EST, weekdays only. Near Ottawa, Ontario Canada

Best of luck

Steve Fox |

bobz1

New member

Username: bobz1

Post Number: 2

Registered: 03-2009

| | Posted on Monday, April 27, 2009 - 01:40 pm: |

|

Thanks steve, I need any and all the help I can get.If you find that catalog please let me know, I sure would like to obtain a copy of it.This engine belongs to a customer who has several racing boats from the same era.However I believe there all 4 strokes. The engine seems simple enough, but theres a few things I don,t quite understand. Like the apparent use of lead to seal the sides of of the jugs (there were no fiber seals just lead ).The caps were back cut to keep the lead in place. there must be a better way to seal this . Epoxy maybe?If anyones has come accross this let me know.I plan on making this a self starter, but judging by the angle holes in the flywheel, this must have had a lever arm of some sort used to spin the engine over to start it. Also by the direction of the angles (4) this must be a reverse rotation engine. I suppose a 2 stroke can run either way. What was most common in 1907. This engine had no magneto on it so does anyone have any idea what it came with.I have an old bosch unit but it would be for looks only as i plan to run an electromotive unit "in cognito".

I'm sure it was mounted at the end of the water pump shaft which is driven 1 to 1, but how and what did it look like. I have no pictures of an original engine so I don't know what any brackets or mag mounts may have looked like.All i need is a photo or an existing part and I can duplicate it.I plan on using modern two stroke oil mixed 20 to 1 with 87 octane fuel . I assume the lack of lead in the gas should not be a problem and may be a benefit (cleaner running).Again Thanks Steve. and if you don't mind I would Like to call you. Bob |

richardday

Senior Member

Username: richardday

Post Number: 742

Registered: 11-2003

| | Posted on Monday, April 27, 2009 - 02:44 pm: |

|

Don't operate without mixing SAE 30 non deteregent in the gasoline. they didn't discover mixing oil 40:1 in the fuel until 1909 and a lot of greife resulted from trying to use drip oilers. Myself I put oil in the drippers but don't drip as this avoids too much oil in the engine. Use a heavy water pump grease in the grease cups and give a 1/2 turn about every twenty minutes was reccomended. With spring loaded grease cups don't have a clue how to deal with that matter. Most of these old timers don't need new rings and unless you can find eliptical rings you will have to turn the modern ring in a stepped collet to reduce the inside diameter otherwise you will build up high friction pressure and make it very hard to get bounce and easy starting. Don't lose the old rings even pieces as you can be in deep trouble trying to find eliptical rings.

Marine engines were as a general rule left handed. That is they turned counter clockwise facing the flywheel. Two strokes will run either way. A left handed engine takes a right handed prop so it really depends on what you plan to do with the engine. Gear water pumps are sensitive to correct rotation so be sensitive to that aspect otherwise you won't be pumping any water.

Plunger pumps are not rotation sensitive.

Well tuned 2 strokes will start simply by priming and rocking the flywheel with a boot. If you pull the flywheel over to start then make sure you have a retarded spark. If you have a spoked flywheel watermen stomped down on the spokes against a retarded which resulted in the engine backfireing and starting to run in the desired rotation. This proceedure requires an real understand of the proceedure and it is not a good proceedure unless you have been taught.

Henry Ford solved the gasket problem with compressible copper gaskets. Early maker used lead sheets in areas not subject to high melting temperatures. |

bobz1

New member

Username: bobz1

Post Number: 3

Registered: 03-2009

| | Posted on Tuesday, April 28, 2009 - 12:24 pm: |

|

Thanks Richard

Now is the 30 w oil better than modern two stroke oil.Or a synthetic. Also back in the early seventies we would run 30 w motor oil in our two stroke go-karts, but I thought it was because it was all we had. Concerning the rings on the vintage cars I always put in aluminum pistons with modern rings and higher compression so originally I planned the same for this engine. But the pistons are a little more complex with that dirverter on top.Also the rings would need to be pinned. The original rings are in great shape so I guess i should re-use them as they are. So should I hone the cylinders if I'm re-using the rings? The waterpump (gear type ) also proves this was a reverse rotation engine, so thanks for that tid bit.But I still don't know what it had for an ignition,since there was nothing on it.As far as starting it. we are still planning on a small hitachi starter with a cover to conceal it.You'll see the ring gear but it makes life easier . The other things i need to know are clearance at the mains and rods. right now the the mains check straight with-in .002 on our cmm and total clearance is .oo45 to .006. Total. I did not get a chance to check the rods yet, but i can machine those to any clearance it needs to be. Again I would like to thank everyone for their help. It sure is appreciated and needed. Thanks Bob |

richardday

Senior Member

Username: richardday

Post Number: 743

Registered: 11-2003

| | Posted on Tuesday, April 28, 2009 - 07:53 pm: |

|

I am an old stick in the mud. AS I understand modern two stroke oil it is intended for high temp/swept piston speeds and these relics are anything but. Ernie prefers two stroke oil if I understand him but its your call. The name of the game is not to starve the lubrication of the moving parts and at the same time make sure not too much burned/unburned oil goes down the exhaust line. |

bobz1

Member

Username: bobz1

Post Number: 4

Registered: 03-2009

| | Posted on Wednesday, April 29, 2009 - 02:11 pm: |

|

Anyone know what this was used for?? Anyone know what this was used for?? |

bobz1

Member

Username: bobz1

Post Number: 5

Registered: 03-2009

| | Posted on Wednesday, April 29, 2009 - 02:24 pm: |

|

This was mounted just after the gearbox.I really have no clue what it could possibly be used for.Anyone with any ideas. Thanks |

bobz1

Member

Username: bobz1

Post Number: 6

Registered: 03-2009

| | Posted on Wednesday, April 29, 2009 - 03:18 pm: |

|

|

bobz1

Member

Username: bobz1

Post Number: 7

Registered: 03-2009

| | Posted on Wednesday, April 29, 2009 - 03:19 pm: |

|

|

keith

Senior Member

Username: keith

Post Number: 248

Registered: 02-2002

| | Posted on Wednesday, April 29, 2009 - 04:31 pm: |

|

Bob,

My guess is there was some form of a timer on the front of the shaft coming from the waterpump. If it appears the missing gear is twice the size of the one on the crank, it was probably a timer. If not, than it may have been for a generator.

I have attached a picture of a UniSparker on a three cylinder.

|

bobz1

Member

Username: bobz1

Post Number: 8

Registered: 03-2009

| | Posted on Thursday, April 30, 2009 - 08:33 am: |

|

Thanks Keith. Any Idea where I could find a four cylinder distributor. Also I need 2 (no 3)oilers , 2 primers and a no 1 grease cup (spring loaded. I can find similar ones on ebay , but not exact. |

bobz1

Member

Username: bobz1

Post Number: 9

Registered: 03-2009

| | Posted on Thursday, April 30, 2009 - 08:34 am: |

|

|

keith

Senior Member

Username: keith

Post Number: 249

Registered: 02-2002

| | Posted on Thursday, April 30, 2009 - 11:12 am: |

|

Bob,

You picked an expensive oiler. The early style Lunkenheimer Paragon #3's go for about $150. Is there any stamping on the greaser? |

bobz1

Member

Username: bobz1

Post Number: 10

Registered: 03-2009

| | Posted on Thursday, April 30, 2009 - 11:28 am: |

|

|

dickie

Visitor

| | Posted on Thursday, April 30, 2009 - 11:47 am: |

|

The mechanism behind the gearbox must have to do with backing up a thrust bearing. Is it linked to the shifter? Does the tail shaft move in/out to engage/dissengage? As for a timer, I would start out with a Ford Model T timer. |

bobz1

Member

Username: bobz1

Post Number: 11

Registered: 03-2009

| | Posted on Thursday, April 30, 2009 - 02:39 pm: |

|

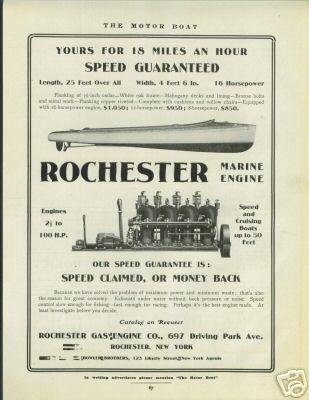

Its not linked to shifter that I can see.Theres no extra holes where maybe a link is missing. Just kind of odd with those two opp. hooks.I bought this ad off of e-bay which shows a similar engine posted below. |

bobz1

Member

Username: bobz1

Post Number: 12

Registered: 03-2009

| | Posted on Thursday, April 30, 2009 - 02:43 pm: |

|

|

bobz1

Member

Username: bobz1

Post Number: 13

Registered: 03-2009

| | Posted on Tuesday, May 05, 2009 - 10:44 am: |

|

Keith

If you have any oilers or know of anyone I can call please let me know. And by the way the engine ad above is very similar to the one I'm rebuilding. So does anyone know what the lever in the back is for? Thanks again for everyones input.This site has been a great help.

Bob |