| Author |

Message |

Chris Mattoon

New member

Username: bwb

Post Number: 3

Registered: 12-2008

| | Posted on Friday, January 30, 2009 - 04:27 pm: |

|

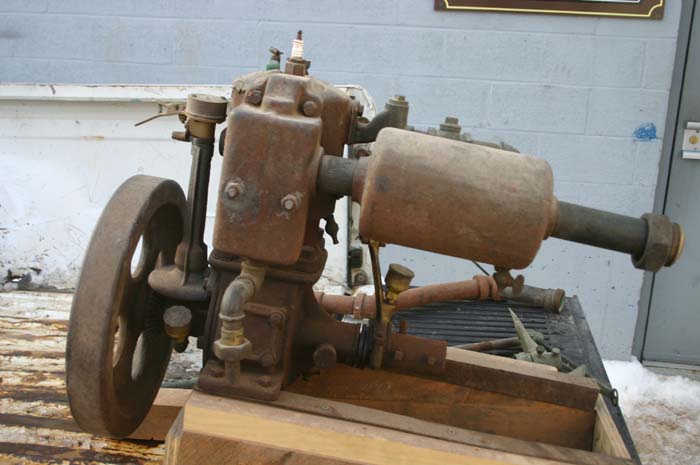

I just picked this up from eastern MA. There are no tags. It is not seized up and has good compression. The repair on the top of the cylinder is ugly, but appears to be sound. Can anyone identify the maker?

|

Roger DiRuscio

Senior Member

Username: solarrog

Post Number: 345

Registered: 03-2002

| | Posted on Friday, January 30, 2009 - 05:08 pm: |

|

I do not know the name of the manufactor, but the cylinder shape is very close to many of the detroit products |

dan kennedy

Member

Username: dan1950

Post Number: 7

Registered: 02-2008

| | Posted on Friday, January 30, 2009 - 07:00 pm: |

|

a grease cup on the end of the crank shaft ?? |

William Schaller

Senior Member

Username: billschaller

Post Number: 211

Registered: 12-2003

| | Posted on Friday, January 30, 2009 - 07:24 pm: |

|

Take a look here.

http://www.antiquengines.com/Detroit_Engine_Works_Menu.htm |

RichardDurgee

Senior Member

Username: richarddurgee

Post Number: 2002

Registered: 11-2001

| | Posted on Friday, January 30, 2009 - 08:15 pm: |

|

*

4 hole flywheel, original green paint, grease cup on crankshaft, Pedestal timer, Pat date stamped in exhaust casting -- That's a "Termaat & Monahan"

** |

Chris Mattoon

Member

Username: bwb

Post Number: 4

Registered: 12-2008

| | Posted on Friday, January 30, 2009 - 09:09 pm: |

|

Can you tell me where they were made, and about what years? |

Chris Mattoon

Member

Username: bwb

Post Number: 5

Registered: 12-2008

| | Posted on Friday, January 30, 2009 - 09:17 pm: |

|

I found the history in the home web page. So, about 1904-1912; made in WI. Interesting. What should I do with the big hunk of weld on the jug - grind it to something less obvious? |

RichardDurgee

Senior Member

Username: richarddurgee

Post Number: 2003

Registered: 11-2001

| | Posted on Friday, January 30, 2009 - 09:29 pm: |

|

*

The early engines up to 1907 Had lever timers, pedestal timers 1908 and later !

Go to search at the top of this page Type in TERMAAT - there are many posts and photos of this engine !

**

** |

Ernie

Senior Member

Username: ernie

Post Number: 930

Registered: 01-2002

| | Posted on Saturday, January 31, 2009 - 09:16 am: |

|

Chris,

Give me a hollar or bring it over and I will show you how to fix the weld. However no matter what you do it will always be partially visable as the grain of he metal will be different due to the weld and grinding

Ernie |

Chris Mattoon

Member

Username: bwb

Post Number: 6

Registered: 12-2008

| | Posted on Saturday, January 31, 2009 - 10:41 am: |

|

Thank you everyone. You have been a big help. Of course, now we will have to build a boat around it. Here is what is left of the original! |

Chris Mattoon

Member

Username: bwb

Post Number: 7

Registered: 12-2008

| | Posted on Saturday, January 31, 2009 - 10:42 am: |

|

Does anyone have a Termaat & Monahan tag or replica that they would like to sell? |

William Schaller

Senior Member

Username: billschaller

Post Number: 214

Registered: 12-2003

| | Posted on Saturday, January 31, 2009 - 11:44 am: |

|

Ernie,

I haven't done it myself , but if the weld is going to be painted, I have always assumed a texture can be put on the weld to hide it. I have thought that it would be possible to use a RTV type mold with a correct texture on it, to overlay the weld. I read a modeling magazine, and if a modeler can make an exact 1/35 replica of zimmerit

http://en.wikipedia.org/wiki/Zimmerit

on a panzer tank, I would think a rough cast texture could be put on a weld. |

Ernie

Senior Member

Username: ernie

Post Number: 931

Registered: 01-2002

| | Posted on Saturday, January 31, 2009 - 05:16 pm: |

|

The point is not to hide it 100 percent so any future owner knows what they are getting.

Example the YT1 or Q1 that I repaired in the last cpuple of years. From a distance they look fine, however when you get close the repair is obvious

I did a BH years ago where I layered on the JB weld covered it in celophane and laid it in a bed of sand. That about 99 percent hid the repair, however it was a pain to get everything perfectly level so the epoxy didn't run. |

Sindre Nilsen

Member

Username: wichmann

Post Number: 23

Registered: 03-2006

| | Posted on Sunday, February 01, 2009 - 03:56 pm: |

|

Is there any other makers, than Termaat & Monahan, who use the grease cup in flywheelcenter patent? |

Keith Billet

Senior Member

Username: keith

Post Number: 230

Registered: 02-2002

| | Posted on Sunday, February 01, 2009 - 08:32 pm: |

|

Ernie,

I would agree with your statement, as to not hiding the repair, when the repair is done with JB Weld or other bondo types. But if the repair is done in such a manner as to duplicate the integrity of the original metal or structure, I see no reason to allow the repair to show.

THOUGHTS? |

John Davis

Senior Member

Username: johnny

Post Number: 174

Registered: 03-2006

| | Posted on Wednesday, February 04, 2009 - 08:21 pm: |

|

Detroit Engine Works also manufactured some of their marine engines using the grease cup on the end of the crankshaft for lubricating the lower con rod. However I believe I would have to agree with Richard that this engine is probably a Termaat & Monahan engine. |

Sindre Nilsen

Member

Username: wichmann

Post Number: 24

Registered: 03-2006

| | Posted on Thursday, February 05, 2009 - 02:24 pm: |

|

Yes, I belive what Richard say, but what about this engine, can that be a Detroit Engine Works?

Link: http://www.oldmarineengine.com/discus/messages/3454/118798.html |

Ernie

Senior Member

Username: ernie

Post Number: 932

Registered: 01-2002

| | Posted on Thursday, February 05, 2009 - 02:33 pm: |

|

Thoughts...

Well the way I have seen some of your repairs, yup as good as or better than it was made so there is not any reason for them to show at all.

However there aren't many that can make the repair in such a manner as to duplicate the integrity of the original metal or structure. In that case my thoughts are to let it show at least a little.

My thoughts...hey you asked |

Keith Billet

Senior Member

Username: keith

Post Number: 233

Registered: 02-2002

| | Posted on Thursday, February 05, 2009 - 04:51 pm: |

|

In any case Ernie, If it was repaired, a buyer should be told. |

Brandon Pineo

Member

Username: bpineo

Post Number: 14

Registered: 05-2008

| | Posted on Saturday, February 07, 2009 - 08:41 am: |

|

Hubbard engines used greese cups on the end of the cranks like the one pictured. Your engine has detroit type features however. |

Ernie

Senior Member

Username: ernie

Post Number: 944

Registered: 01-2002

| | Posted on Sunday, March 29, 2009 - 12:02 pm: |

|

It is a 3 hp Termatt and Monahan

Here it is with the extra braze ground off.

Considering the quality of the weld I will most likely leave it as it is.

It runs good too!

Does anyone have a Termatt and Monahan tag? Or a hi res pic of the tag straight on and a pencil rubbing scanned full size. The tag on this one was between the oiler and the timer. You can see one of the screws in the pic.

|

Robert

Senior Member

Username: robert

Post Number: 265

Registered: 07-2003

| | Posted on Tuesday, March 31, 2009 - 11:48 pm: |

|

With some Walter 'Quick Step' pads on an angle grinder you should be able to fair that weld in so it is very hard to detect under paint. That or just a lot of work with a file etc. |