| Author |

Message |

Barry Millar

Senior Member

Username: barry

Post Number: 65

Registered: 02-2006

| | Posted on Monday, April 28, 2008 - 01:57 pm: |

|

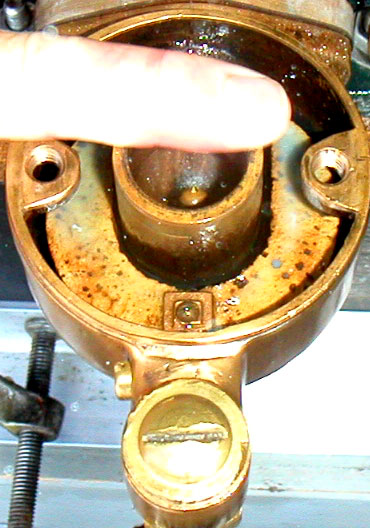

Attached is an interesting image of a Schedler model D with top cover removed during engine operation. The gasoline spray pattern is visible.

When the air horn and float chamber cover are both removed, it’s necessary to reduce air flow as shown using a "finger" throttle to maintain an air/fuel mixture within combustible range.

The same occurs by opening the needle valve. For example during normal operation of a 2.5 HP two cycle engine, the needle is about one half turn open. When the air horn and float chamber cover are removed, the engine operates normally when the needle is opened to one turn.

If only the compensating air valve is removed, the engine operates over a full speed range with the needle valve set at about three quarters open.

Another test demonstrated that the 2.5 HP engine continues to operate at constant RPM for about 3 minutes when fuel supply is turned off, until fuel level drops to about one inch below spray nozzle, then the engine just stops. By adding gasoline to about three quarters of an inch below spray nozzle the engine starts normally and runs for about a minute.

I suppose this shows that float setting is not critical.

Barry

|

Ernie

Senior Member

Username: ernie

Post Number: 808

Registered: 01-2002

| | Posted on Monday, April 28, 2008 - 04:30 pm: |

|

Barry,

The only time I have found the float setting critical is a bouncy/jumpy show engine. In that case it needs to be as low as possible.

My 3 hp Gray in the fantail launch doesn't care as long as it is consistant. Meaning that the float level stays where it was when I set the needle valve. |

John Archibald

Senior Member

Username: john_archibald

Post Number: 60

Registered: 08-2006

| | Posted on Thursday, May 01, 2008 - 08:01 pm: |

|

Folks,

I just bought a 1919 vintage Schebler Model D Carburetor manual and paid a hefty price for all 4 pages. However, there were some fine points about the operation of these carburetors on vintage engines that I thought were interesting and to that end if anyone wants me to send them 4 images comprising the whole catalog I will do so free of charge as a service to the group.

Just e-mail me with the request.

Regards,

John Archibald

. |

Ernie

Senior Member

Username: ernie

Post Number: 810

Registered: 01-2002

| | Posted on Thursday, May 01, 2008 - 08:44 pm: |

|

John,

Is it the same as these?

Schebler

Just to save you copying yours... |

John Archibald

Senior Member

Username: john_archibald

Post Number: 61

Registered: 08-2006

| | Posted on Thursday, May 01, 2008 - 10:41 pm: |

|

Ernie,

Yes, almost identical.

Archibald

. |

Maury Polse

New member

Username: capmo

Post Number: 1

Registered: 06-2008

| | Posted on Thursday, June 12, 2008 - 05:39 pm: |

|

Ahoy,

I've a twin 14hp Hicks in 'DIXIE'the 1924 DiMaggio Monterey Clipper fishboat that I use for tours, sometimes 7 day a week. What about replacement of the cork float with brass? Our Calif. gas has methanol and even draining the bowl every day the shelac and even epoxy turns to mush. I've seen a few for the tractor carb that have twin floats and look as they could be altered to do the job. |

RichardDurgee

Senior Member

Username: richarddurgee

Post Number: 1715

Registered: 11-2001

| | Posted on Thursday, June 12, 2008 - 05:57 pm: |

|

*

Capt Maury

Dave Reed sells Pauls floats at this web site they are Great!

http://www.pistonrings.net/

CARB FLOATS

http://www.dol.net/~dave.reed/carbsche.htm

P.S. I still have the original single 8Hp hicks

that came out of your Boat and am looking for a magneto for it !

* |

Todd Vidgen

Advanced Member

Username: todd_vidgen

Post Number: 44

Registered: 03-2008

| | Posted on Thursday, June 12, 2008 - 06:09 pm: |

|

We are using floats from Omc out board motors

and modifying them They are the right diameter

to start with and with the dexterous use of a

band saw and bench grinder or drum sander you can

make a good float.We actually have jigs when we make them because we make 50>100 at a time.

They are impervious to the effects of modern fuels

including ethanol blends.

You have to make a couple of small modifications

to the bowl of the carby

1 Slightly grind out the underside sections where

the two 1/4 ' bolts that hold the air horn and carby together thread into.

2 Slightly grind the top inside face of the bowl

around the side of the float arm pivot for about

1 inch either side and for about 1/4 to 3/8 inch

down

These two processes allow you nto fit the float

without flexing and damaging it as they dont bend

like cork

We have had no failures as yet from fuel

and we have been making them for more than 4 years

Some people have broken them by forcing them into

the bowl(sorry no waranty on that) |

chuck fanucci

Visitor

| | Posted on Wednesday, January 21, 2009 - 12:00 am: |

|

My schebler model D 3/4 inch leaks fuel out of the air intake. it is being used in the vertical mode. The float level seems correct,is it possible to have a leak around the needle valve housing? Does it have a packing or gasket in there. It is not flooding over and leaks no matter what the float level is. |

chuck fanucci

Visitor

| | Posted on Saturday, January 24, 2009 - 12:20 pm: |

|

I Loosened the air valve adjuster and the dripping stopped. |