| Author |

Message |

ernie

Senior Member

Username: ernie

Post Number: 687

Registered: 01-2002

| | Posted on Monday, July 09, 2007 - 03:57 pm: |

|

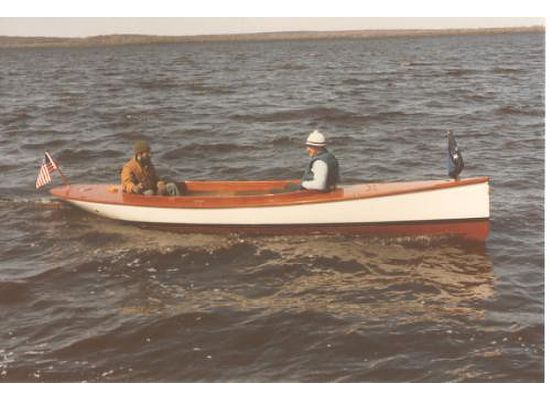

It was nice here today so I got the Fantail in the water.

Over the last couple of days I got the engine to start, run and reverse on the switch real well in my yard on the trailer. I was really suprised to find out it didn't run any differntly in the water. I didn't even need to change any of the carb settings. I guess I was amazed everything worked as advertised.

More pics from when I got this boat till launching are click here

|

miro

Senior Member

Username: miro

Post Number: 283

Registered: 11-2001

| | Posted on Thursday, July 12, 2007 - 07:05 pm: |

|

atta boy Ernie - she looks just fine -

miro |

andrew

Moderator

Username: andrew

Post Number: 884

Registered: 11-2001

| | Posted on Thursday, July 12, 2007 - 08:14 pm: |

|

Great job Ernie ! Looks wonderful.

|

ernie

Senior Member

Username: ernie

Post Number: 693

Registered: 01-2002

| | Posted on Thursday, July 12, 2007 - 08:31 pm: |

|

Gee thanks everyone

Pics were taken on Monday, still grinning on Thursday |

ernie

Senior Member

Username: ernie

Post Number: 695

Registered: 01-2002

| | Posted on Saturday, July 14, 2007 - 07:04 pm: |

|

Pics from my deck looking down on the boat

|

ernie

Senior Member

Username: ernie

Post Number: 698

Registered: 01-2002

| | Posted on Wednesday, July 25, 2007 - 03:11 pm: |

|

The fuel system is a plastic outboard tank under the bow seat. The little square thing on the engine below the timer is an OMC fuel pump. The pink things are absorbant pads. However I almost have a Schlebler that doesn't drip now that it has a viton tip needle and new brass seat. So maybe I won't need them any longer.

You will note the coil box is in different places in different pics. I wasn't sure where I wanted it so I put long wires on it. I think I will leave it that way so it is convient to where the boat is run from. Using the boat alone I sit in front of the engine on a little stool. If there are others in the boat I run it from behind the enigne. I am running it with a Ford coil and gel battery.

|

ernie

Senior Member

Username: ernie

Post Number: 699

Registered: 01-2002

| | Posted on Wednesday, July 25, 2007 - 03:14 pm: |

|

More pics

|

richardday

Senior Member

Username: richardday

Post Number: 509

Registered: 11-2003

| | Posted on Wednesday, July 25, 2007 - 08:52 pm: |

|

Great work Ernie. Are we going to get to ride in it at Mystic? Looking forward to seeing it and riding in it. |

ernie

Senior Member

Username: ernie

Post Number: 700

Registered: 01-2002

| | Posted on Thursday, July 26, 2007 - 07:45 am: |

|

Yes the plan is to take it to Mystic |

ernie

Senior Member

Username: ernie

Post Number: 701

Registered: 01-2002

| | Posted on Thursday, August 02, 2007 - 07:06 pm: |

|

Went out today and took my GPS. Calculated hull speed is aprox 5.5 knots or 6.7 MPH.

Doggone if it doesn't do that.

Max I could get was 5.4 Knots and then I changed the GPS to MPH and got 6.7 MPH. However I think I may try a smaller prop. The engine doesn't rev up much. (havn't taken my tach out with me yet)

At idle barely running it is still going around 4 Knots. |

billschaller

Senior Member

Username: billschaller

Post Number: 136

Registered: 12-2003

| | Posted on Friday, August 03, 2007 - 10:09 am: |

|

at that riproaring speed, you may have wished you put a tranny in there. |

ernie

Senior Member

Username: ernie

Post Number: 702

Registered: 01-2002

| | Posted on Friday, August 03, 2007 - 03:06 pm: |

|

Nope just a smaller prop. |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 271

Registered: 07-2002

| | Posted on Friday, August 03, 2007 - 08:58 pm: |

|

Ernie, what prop do you want to try, may have something, could bring it to Mystic. Diameter, pitch, 1"tapered shaft? Most I have are three blade. |

ernie

Senior Member

Username: ernie

Post Number: 703

Registered: 01-2002

| | Posted on Saturday, August 04, 2007 - 07:30 am: |

|

JB,

I have a 13x13 3 blade 1" shaft on it now. I am thinking 12x12 3 blade. I have an 11x11 and a 10 by something. The shaft is actually 7/8 but I have been using a bushing to 1 inch since 7/8 props are not all that common. It's all a guess anyway so you can see my thinking. A little more RPM won't be a problem since it doesn't rev up much now.

Thanks

Ernie |

barry

Advanced Member

Username: barry

Post Number: 45

Registered: 02-2006

| | Posted on Saturday, August 04, 2007 - 08:27 am: |

|

Ernie,

I am very interested in learning more about the innovations that you added to your Rose launch.

1 Fuel pump with Schebler model D carburetor

Do you know a part number for a low pressure crankcase driven pump that is commonly available that includes a hose or NPT crankcase connection. I suspect that most pumps are flange connected. I would like to purchase a pump and experiment with it using my test bench, then maybe add a pump to my boat engine.

Using a top mounted fuel tank connection or portable “outboard” fuel tank has an appeal.

I would have thought that the high pump output pressure compared to gravity feed would increase Schebler float valve leaking, however you report the opposite. Can you enlighten me about this as I am also very interested in ways to eliminate Schebler model D dripping and/or leaking.

2 Viton float valve

How did you manufacture the valve? I attempted to manufacture a valve using Viton for the seat but found it too rubbery to machine. I am currently experimenting with Delrin seats but this material while easy to machine does not have the desirable “soft” properties as does Viton.

3 Exhaust

Your exhaust set-up is most enlightening as the muffler is below engine exhaust outlet, below the waterline and below the through hull. This is a great method providing the muffler and horizontal exhaust pipe do not fill will cooling water as to present back pressure during starting. I’m guessing that cooling water collects in the bottom of the muffler when engine is shut down and does not block the exhaust. Your method is a major advantage as it avoids exhausting through the side of the hull which encroaches on passenger space.

4 Propeller

Just for information, I use a 12D x 14P three blade. My engine is similar to yours, 3 1/4 B X 3 1/2 S. The propeller hold max RPM to 850. The vessel drives at hull speed. For my engine 850 RPM is the engine speed that produces maximum torque.

Barry |

ernie

Senior Member

Username: ernie

Post Number: 704

Registered: 01-2002

| | Posted on Saturday, August 04, 2007 - 09:13 am: |

|

Barry,

1 fuel pump is from a small OMC (Evinrude/Johnson) outboard. NAPA sells them cheaper than OMC. For an exact model tell them you want a pump for a 1970 6 hp. They flange mount so I used a pice of 1/4 thick aluminum drilled and tapped for the pump screws and drilled and tapped 1/8 pipe for the connection to the crankcase. The pipe to the crankcase has a blob of solder in it that is drilled .029 to restrict crankcase pressure some.

2 Needle and Seat

I knew someone was going to ask about the needle and seat. I have no idea what it came out of. My best guess is an Echlin (NAPA) carb kit. The bag is marked GO 25-316A

I cut the nub off the needle that held the float spring to shorten the needle as much as possible.

I set the carb up in my milling machine and milled the existing Schlebler seat area flat. I then drilled and tapped for the seat. 5/16-24 I think. The carb I am using as from a Cushman Binder engine and had a fabrucated float arm. I modified it to push on the needle. The Cushman carb also has a conventional throttle plate. I think the throttle control is better than the traditional schlebler style.

3 The exhaust is just what I have seen and used around New England all my life. It should have a vaccuum break in the line from the engine to the water injection elbow. However the boat doesn't live in the water and the height differences aren't much. I do run the engine in reverse (gear pump so it doesn't pump water in reverse) till the exhaust gets loud (blow all the water out of the exhaust) if I am going to leave it for a while. I have had no problems starting due to backpressure in the exhaust. If by some chance the exhaust fills with water I have a drain in the muffler. There is also 7 feet of surflex exhaust hose stuffed in under the rear seat and aft deck. Between the muffler and the hose it is real quiet.

4 Prop

I have not had a tach in the boat. Simply by ear it probally isn't running over 500 RPM if that. I believe the engine is rated at 500 RPM anyway. Also this model of Gray has no counterweights or balance in the flywheel. The 13x13 prop will actually push the boat a little over hull speed. I would actually like to end up around 4.5 MPH as the boat is real comfortable there. I would also like to be able to slow it down a little more. It will be easier to dock and reverse that way. I may try the 11x11 3 blade that I have today. |

ernie

Senior Member

Username: ernie

Post Number: 705

Registered: 01-2002

| | Posted on Saturday, August 04, 2007 - 06:47 pm: |

|

I just looked up the part in a 1970 OMC parts book. The OMC part number is (or was)

382875 fuel pump assy

Hope this helps

Ernie |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 272

Registered: 07-2002

| | Posted on Saturday, August 04, 2007 - 11:08 pm: |

|

Ernie, I have 2 13X12LH and 2 14X10LH, don't know which direction you run you engine, we use left hand props. If you want to try them let me know, I'll bring them with me. |

ernie

Senior Member

Username: ernie

Post Number: 706

Registered: 01-2002

| | Posted on Sunday, August 05, 2007 - 08:32 am: |

|

JB,

I am using RH. Due to the gear type water pump I don't have much choice.

Thanks for looking

E |

andrew

Moderator

Username: andrew

Post Number: 885

Registered: 11-2001

| | Posted on Sunday, August 05, 2007 - 10:59 am: |

|

Part 382875 was superceded to:

388685 FUEL PUMP&SCREW AY $59.49

Some less expensive OMC/Johnson/Evinrude type pumps can be see here. |

miro

Senior Member

Username: miro

Post Number: 329

Registered: 11-2001

| | Posted on Tuesday, June 17, 2008 - 12:24 pm: |

|

I can hardly believe my eyes.

The Rose launch and Gray engine experience has left Ernie speechless.

But that's what old engines in old style boats tend to do :-}

miro |

ernie

Senior Member

Username: ernie

Post Number: 831

Registered: 01-2002

| | Posted on Tuesday, June 17, 2008 - 03:53 pm: |

|

Hey even more so than the "mobile malt beverage storage module"

I just wish I could find time to get it in the water this year. I havn't touched since I put it away last fall. |

ernie

Senior Member

Username: ernie

Post Number: 842

Registered: 01-2002

| | Posted on Monday, June 30, 2008 - 07:35 pm: |

|

New battery and coil box.

I ran out of electricity once last year. Don't intend to let that happen again. Knife switches allow either or both batteries.

|

miro

Senior Member

Username: miro

Post Number: 333

Registered: 11-2001

| | Posted on Thursday, July 03, 2008 - 11:59 am: |

|

But Ernie - have you tested it out yet?

Summer's in full bloom now and you've just gotta get that boat wet.

Miro |

kerrigan

New member

Username: kerrigan

Post Number: 2

Registered: 06-2008

| | Posted on Thursday, July 03, 2008 - 01:28 pm: |

|

Wot? No dovetail joints on the battery box! |

ernie

Senior Member

Username: ernie

Post Number: 843

Registered: 01-2002

| | Posted on Thursday, July 03, 2008 - 05:59 pm: |

|

Yup and it kicked my but on day 1. Dirt in the carb.

Day 2 yesterday was perfect ran it a lot and it worked as advertised.

I did pick up a nice Baldrige reverse gear at the Orange MA show. Number 5 or 6. I definatly DO plan on installing it over the winter.

Dovetail joints??? It's lucky it got oak trim and polyurethane. Cosmetics and I don't get along. The boat still has peeling blue paint on the deck. You see it's good to have future projects!

Peeling blue paint can be viewed a Mystic if they can launch it for me. |

ernie

Senior Member

Username: ernie

Post Number: 844

Registered: 01-2002

| | Posted on Thursday, July 03, 2008 - 06:05 pm: |

|

Here are pics of the gear. I have plenty of room to install it.

|

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 377

Registered: 07-2002

| | Posted on Friday, July 04, 2008 - 10:26 am: |

|

Ernie, you're going to take all of te fun out of docking, missing reverse and taking off wide open forward. That's a nice looking gear and should make it a pleasure to handle. |

ernie

Senior Member

Username: ernie

Post Number: 863

Registered: 01-2002

| | Posted on Saturday, August 23, 2008 - 09:30 am: |

|

Thanks to Scott at the Mystic Seaport I finally have pics of the boat under way. The passenger is Bob Long

Pics were taken at the 2008 Antique Marine Engine Exposition at the Mystic Seaport in Mystic, CT

|

bcm

Member

Username: bcm

Post Number: 4

Registered: 11-2009

| | Posted on Tuesday, March 16, 2010 - 05:47 pm: |

|

Ernie,

I’m arranging to install a rebuilt I920s two stoke engine in a new boat. I will use a portable fuel tank of the type used for outboard motors so will be installing a vacuum fuel pump using crankcase power from one of the cylinders. This will also provide fuel withdrawal from tank top, a desirable installation.

The carburetor is Schebler D.

I will appreciate receiving information and suggestions that resulted from your experience.

I understand from studying this posting and the images of your fuel pump installation, you have successfully adapted an OMC # 382875 fuel pump to your Gray engine.

My chief concern has to do with limiting and controlling the fuel pressure so as to avoid forcing the Schebler valve stem away from the seat thus causing carburetor flooding realizing that a gravity feed probably presents a pressure of only about ½ psi at the fuel connection. I note you modified your carburetor thus am concerned that a standard Schebler may not seal against excessive fuel pump pressure.

Have you performed any tests of fuel pressure? How is this pressure controlled when fuel use changes during low and high speed operation?

Thank you in advance for advice on this subject.

B Millar |

ernie

Senior Member

Username: ernie

Post Number: 1176

Registered: 01-2002

| | Posted on Tuesday, March 16, 2010 - 07:02 pm: |

|

Barry,

Boat is still covered up and I don't see it out any time soon.

No idea as to fuel pressure. I guess you could look up the pressure spec for a 6 hp 1965 Evinrude.

I did restrict the pressure pipe with a blob of solder and then drilled a .070 in hole. I suspect this may lower the pressure some.

As to the needle and seat the new replacement needle and seat I am using works perfect. I wish I remembered what it came out of. All I can tell you on it is that it came out of an OMC carb.

Hope this helps

Ernie |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 518

Registered: 07-2002

| | Posted on Tuesday, March 16, 2010 - 09:47 pm: |

|

Run a return line to the tank after the pump, use a restiction to raise pressure to the desired level, this will bleed pressure when engine is stopped to prevent flooding. Chrysler used an inline filter with a third tap for vapor return. I've used these for this type installation, the vapor return hole is very small, it may have to be drilled. It would be wise to install a primer bulb for starting. |

ernie

Senior Member

Username: ernie

Post Number: 1177

Registered: 01-2002

| | Posted on Wednesday, March 17, 2010 - 07:56 am: |

|

The pressure pipe mentioned above is the one to the crankcase to operate the pump. Not the pump outlet. A restriction in the pump outlet only restricts flow not pressure. |

bcm

Member

Username: bcm

Post Number: 5

Registered: 11-2009

| | Posted on Wednesday, March 17, 2010 - 09:19 am: |

|

Thanks for info, Ernie,

I’ll plan to use my test bench to obtain this information. I have in mind to set up and operate an engine to power a fuel pump to a second carburetor , take the cover off this carb for observation then crack the carb drain valve to simulate fuel use, then record pressure fuel pressure and crankcase pressure/vacuum.

I’ll take up your suggestion to install a means to throttle the pressure/vacuum supply and to be able to adjust this to determine resultant fuel pressure.

Should have information to report sometime in May.

I previously posted some images showing a Schebler D with cover removed during engine operation. I was interested in obtaining an understanding regarding the interaction between the float and float valve. I concluded that the valve “dances” rapidly but may not fully close other that when the engine is stopped. Thus (within limits) the fuel pressure resulting from tank elevation or use of a fuel pump may not be critical.

Image attached for interest.

bcm

|

bcm

Member

Username: bcm

Post Number: 6

Registered: 11-2009

| | Posted on Wednesday, March 17, 2010 - 10:17 am: |

|

Thanks JB,

I’ll include a return line in my test set up. This sure makes sense as the way to set and control fuel pressure. Probably will use an easily replaceable insert with drilled hole so that I can establish ideal orifice size and resultant fuel pressure.

Pressure bleed off when engine is stopped is a huge plus as to avoid static fuel leak due to a less than perfect valve/seat.

Would you please explain the set-up and function of the vapor return line.

thanks

bcm |

ernie

Senior Member

Username: ernie

Post Number: 1179

Registered: 01-2002

| | Posted on Wednesday, March 17, 2010 - 11:45 am: |

|

See if you need it first!

Mine works fine without it

Also lets move this thread to the carb area as there are waaayyyy toooo many pics here already and in a while no body will be able to find it.

By the way what is the reason for changing your name? |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 519

Registered: 07-2002

| | Posted on Friday, March 19, 2010 - 06:21 am: |

|

The vapor return line was used on many carburated cars to help reduce vapor lock. It was a small return line that allowed vapor to return to the tank. In the mid 70's Chrysler products used 5/16" inline filter with a third 1/4" port, it had a small orfice in it. I used these on some industrial equipment that had Wisconsin V4 engines, installed electric fuel pumps, pressure was too high for the carb. |

Ned Lloyd

Visitor

| | Posted on Thursday, April 01, 2010 - 01:22 pm: |

|

I wonder if I might have been involved in originally building your launch? I built a number of them (one steam, a couple gas, and a couple electric) while working at a yard in R.I. in the early 1980's.

|

ernie

Senior Member

Username: ernie

Post Number: 1180

Registered: 01-2002

| | Posted on Thursday, April 01, 2010 - 05:55 pm: |

|

Could be as I have no idea where it was built. It is registered as home built.

It isn't a Beckman. The one Beckman builds is very similar but when you look close there are a ton of differences.

I was told it was steam to begin with and when I got it there was still a water tank in the bow.

Who did you work for?

click on my name at the left for my e-mail.

If you are sill in RI come over for a look and ride as soon as it gets warm.

Thanks

Ernie |

Ned L

Visitor

| | Posted on Monday, April 12, 2010 - 03:47 pm: |

|

Well, its not one I was involved with. I worked at "Rhode Island Marine Services" back in the early 80's, & that is where I built those launches. That yard was ownded by Walter Beckman. |

ernie

Senior Member

Username: ernie

Post Number: 1357

Registered: 01-2002

| | Posted on Wednesday, June 29, 2011 - 03:27 pm: |

|

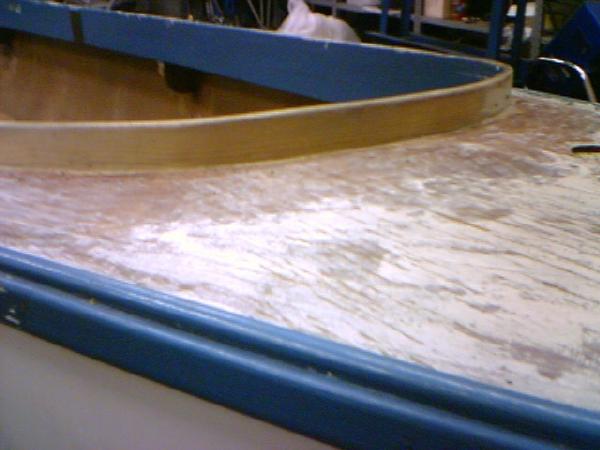

The horrible blue paint is finally leaving! Initially the coaming looks good enough to handle varnish. The deck is plywood and will be painted some shade of tan. The rub rails will hopefully clean up ok so they can also be varnished.

|

ernie

Senior Member

Username: ernie

Post Number: 1360

Registered: 01-2002

| | Posted on Tuesday, July 05, 2011 - 08:04 am: |

|

Paint removal is NO fun but he end result is. Still lots more to go.

|

billschaller

Senior Member

Username: billschaller

Post Number: 429

Registered: 12-2003

| | Posted on Tuesday, July 05, 2011 - 11:33 am: |

|

Ernie,

shouldn't you do this work during the winter, and go boating in the summer? |

ernie

Senior Member

Username: ernie

Post Number: 1361

Registered: 01-2002

| | Posted on Tuesday, July 05, 2011 - 07:22 pm: |

|

Believe it or not there is A/C but no heat where it is |

ernie

Senior Member

Username: ernie

Post Number: 1362

Registered: 01-2002

| | Posted on Wednesday, July 06, 2011 - 08:34 am: |

|

|

ernie

Senior Member

Username: ernie

Post Number: 1363

Registered: 01-2002

| | Posted on Thursday, July 07, 2011 - 03:16 pm: |

|

|

ernie

Senior Member

Username: ernie

Post Number: 1364

Registered: 01-2002

| | Posted on Friday, July 08, 2011 - 02:46 pm: |

|

3 quarts of paint remover and lots of sand paper later...

Oh yea about 15 hours too

Now need to get some mahonany to replace the piece of 2x4 that was wrapped around the stern then finish sand the all the wood work one last time. The coaming, toe rails and rub rails will be varnish. The deck will be tan as it is plywood and is in no condition to be varnished.

|

keith

Senior Member

Username: keith

Post Number: 330

Registered: 02-2002

| | Posted on Friday, July 08, 2011 - 04:18 pm: |

|

Not to make your job more difficult Ernie, but wouldn’t a canvas deck be neat? |

ernie

Senior Member

Username: ernie

Post Number: 1365

Registered: 01-2002

| | Posted on Friday, July 08, 2011 - 05:57 pm: |

|

Yea

BUT... |

johnny

Senior Member

Username: johnny

Post Number: 404

Registered: 03-2006

| | Posted on Friday, July 08, 2011 - 07:19 pm: |

|

Looking good Ernie! |

ernie

Senior Member

Username: ernie

Post Number: 1377

Registered: 01-2002

| | Posted on Monday, July 25, 2011 - 01:44 pm: |

|

The hardest part

Ended up being 2 1/8th in thick strips laminated with epoxy as I no longer have a steam box.

From this...

To this...

|