| Author |

Message |

Searcher

Senior Member

Username: searcher

Post Number: 244

Registered: 10-2004

| | Posted on Saturday, June 21, 2008 - 12:17 am: |

|

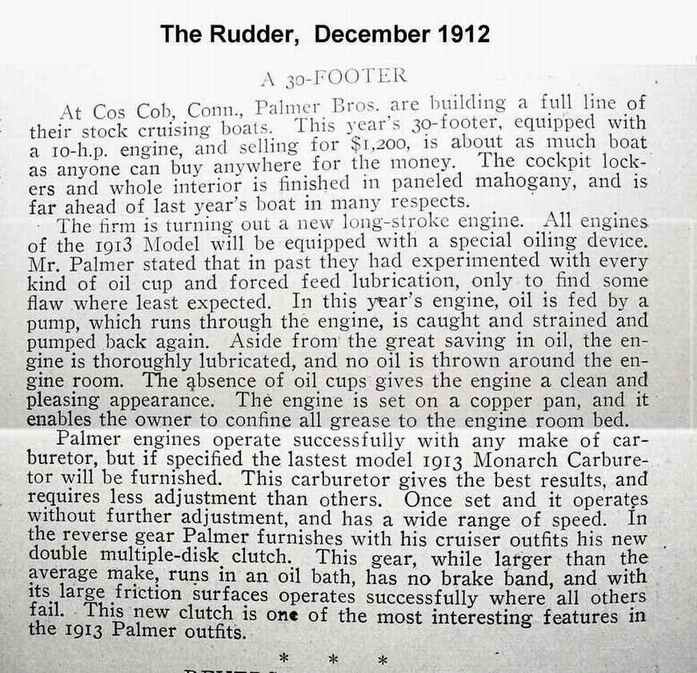

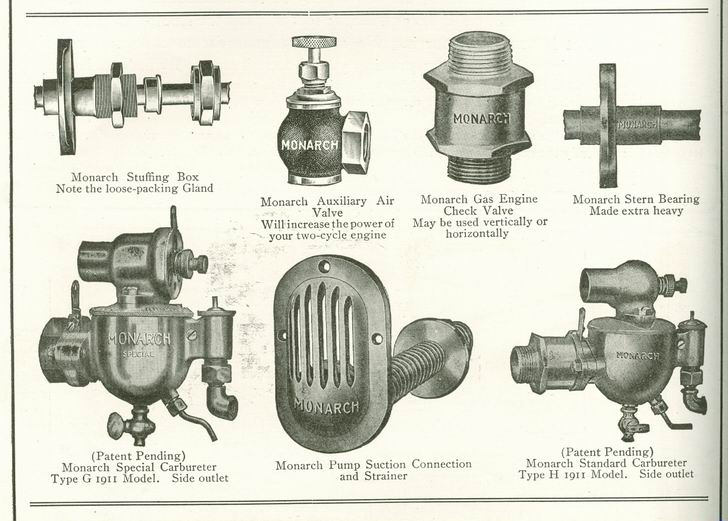

The reference to the Monarch carburetor is useful for nerds like me that wonder what the correct parts might be for a piece of old iron. Palmer seems to favor the Monarch at that point in time.

|

RichardDurgee

Senior Member

Username: richarddurgee

Post Number: 1724

Registered: 11-2001

| | Posted on Saturday, June 21, 2008 - 02:50 pm: |

|

*

* |

Richard A. Day Jr.

Senior Member

Username: richardday

Post Number: 622

Registered: 11-2003

| | Posted on Sunday, June 22, 2008 - 10:42 am: |

|

________________________________________

Last night I wrote a long post and proceeded to lose it some how. Will try again to give my opinion on Searchers comment regarding what the correct items should be on this old iron.

I had never seen the clip posted before. I had trouble at first understanding the "copper pan". Not the brightest in my age group. Palmer was talking about a separate pan under the engine which is mounted on the typical wooden engine mounts. It simply collects the drips which I am sure were plenty.

The engine models they are talking about in the 1913 ad are the models NL (New L) and NR (New R ) which were released for sale in Dec. 1912. These engines were T head four stroke. NL 4-1/2"B, B/4-1/2"S, NR 5"B, 6"S.

They were in 1,2,3 and 4 Cylinders. They were the first Palmer engines with oil pumps. There is one 2 cylinder survivor of this first period. Palmer had not isolated the crankcase oil of the engine from the reverse gear oil. This resulted it in all the oil running back to the reverse gear and starving the pump. They quickly corrected this situation by isolating the two crankcases. The oil pump was in the engine crankcase and it simply pumped oil up to the top of the intermediate gear where it drained back into the wells under each crankcase throw. We know this from their 1914 catalog discussion.

These were "headless" engines and their outside appearance was for practical purposes identical only the NL was smaller than the NR. They were superseded by the ZR series in 1925. The significant differences of the ZR series were 5-1/2"B, 6"S, counterbalanced crankshaft, different reverse gear, post 1927 water heated intake manifold on the 2,3 and 4, and detachable head cylinders. The last ZR-4 was made in 1957 and is still in operation. The last ZR-1s were made in 1962.

Some of the parts for the NL and NR such as oil pump, water pumps, timer drive gears, valve push rods and guides were in production until 1962.

In the earlier Palmer Catalogs for the models 1900 era, Models B,C,D and E, Palmer used their own mixing valve and at some date not known to me they began using Schebler model D and they would supply a customer specified carburetor of the period.

There were a number of knock offs of the Schebler Model D such as Monarch, Michigan Wheel, Acorn, Generator Valve, etc. There were other float feed carburetors such as Krice which in the early years was favored by Gray among other big makers.

There was a constant search for the better carburetor for more power, less fuel consumption, etc.

In my opinion any carburetor of the period is appropriate for the engine unless one has a photo or print which shows an original carburetor used by the engine maker which is unique. Some makers made their own carburetors or mixing valves. While a period carburetor may be on the engine and the engine works well I would search for the probable original type carburetor or mixing valve.

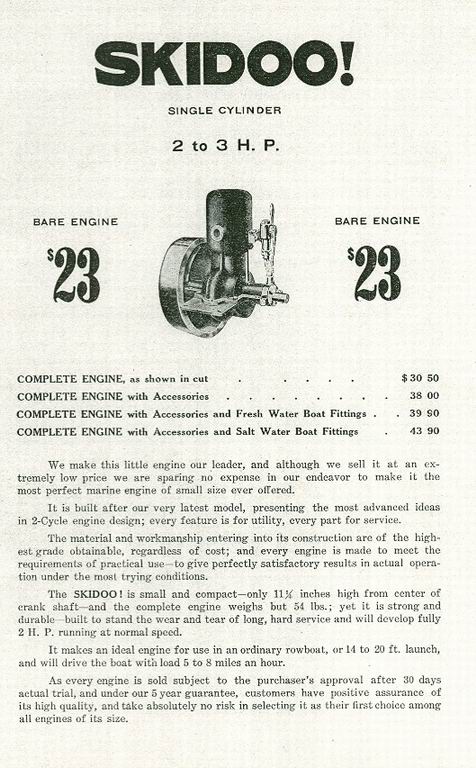

I have a Belle Isle with a float feed mixing valve which came on the engine when I found it 40 years ago. It had been on the engine a long time but I have no idea what Belle Isle actually shipped on their engines.

There was an outboard motor some years back at the Mystic show which had the identical mixing valve on it but the owner had no idea if it was original to the engine. Still looking for clues and I hope Richard will come up with the answer to that puzzle.

Mixing valve went out of favor in boats due to leakage at the worn valve seat. My experience with Schebler Model D is they drip. So do the knock offs for that matter. Very few don't drip new or used. I think Ernie Darrow with the Viton tip has solved that problem.

Back before WWII I well remember boaters with an inboard engine had a small rectangular copper or brass tank with a fine mesh brass screen hung under their carburetors to catch any drips.

Any collected was dumped over the side I guess I should admit.

This tank wasn't necessary if you had a Ford V-8 conversion with its downdraft carburetor. While many responsible boaters of the period 1920-40 had backfire traps they were not required until the safe boating act was passed in 1940.

From my experience with the these four stroke Palmer engines of I have not figured out how to stop oil ooze at the pump plunger, crankcase breather valves and the aft shaft seal at the shaft coupling. In the early years Palmer used a strange wiper shaped like centrifugal pump impeller just inside the aft end of the reverse gear to pump the reverse gear oil back into the case of the reverse gear. I quickly found this is not very effective. I put an O ring around the shaft and squeezed it reasonably tight between the coupling to the aft face of the reverse gear. That solves that leak but it would not have solved it for Palmer in those early years as they didn’t have oil resistant O rings. They later went to leather seals.

The oil pump I put O rings on the pump plunger and that cuts the ooze pretty well but there is no solution to the crankcase breather valves for the single cylinder NL, NR or ZR I have figure out. In four stroke closed crankcase single cylinder engines the breather valve acts to create a vacuum in the crankcase which is does pretty effectively. In modern engines these valves often are mounted in the valve compartment of the engine and often are connected with a short tube to the intake of the carburetor which removes any excess oil. The external Palmer breath valves tend to drip small amounts of oil.

Most of the workboats I saw years ago around Chesapeake Bay with big old one lungers looked like they could use a little cleaning up. Hey it wasn't an easy way to learn a living and now they are all gone. So have the oysters, clams, crabs and fish have just about disappeared due to serious pollution and over fishing.

Back to Searcher's point regarding what is the correct part. In the case of Palmer it appears to me by 1914/16 they had stopped making their own timers and had switched to the Cuno timer on all their timer driven ignition systems. They had made their own timers up to about 1914 but few survive. They used the Magnetos and the Atwater Kent system on some of their multiple cylinder engines up until the mid 1930s. Magneto or automotive style ignition remained on some engine models until the end of production in 1971 |

RichardDurgee

Senior Member

Username: richarddurgee

Post Number: 1726

Registered: 11-2001

| | Posted on Sunday, June 22, 2008 - 09:22 pm: |

|

*

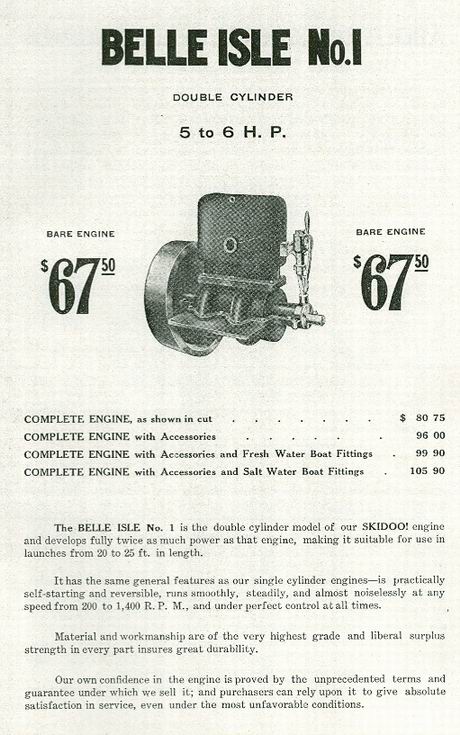

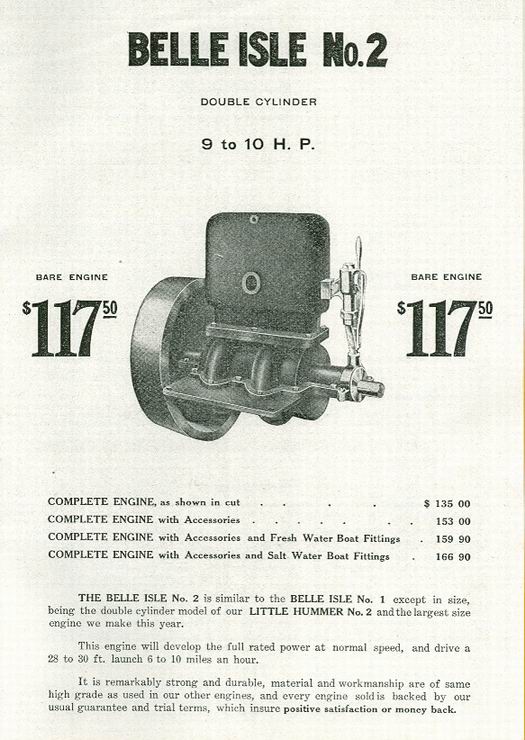

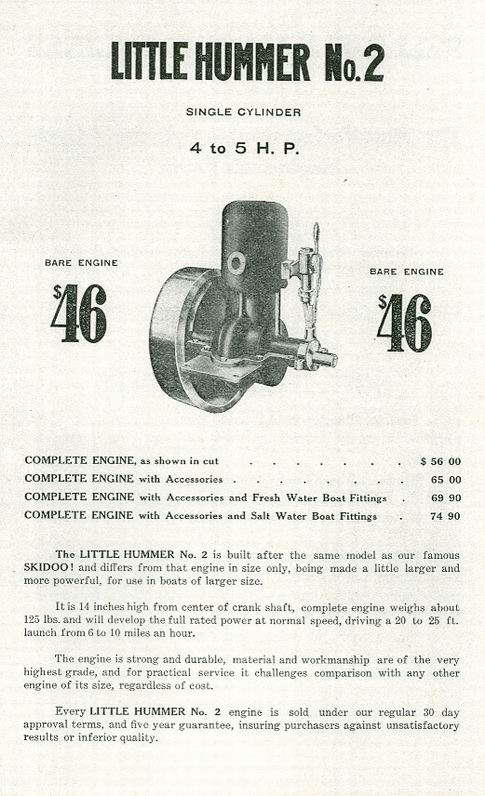

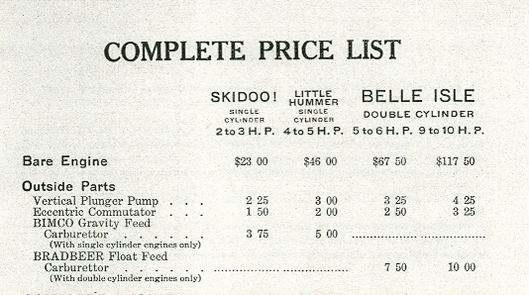

Belle Isle engines and carburetor info 1907

* |

Richard A. Day Jr.

Senior Member

Username: richardday

Post Number: 623

Registered: 11-2003

| | Posted on Monday, June 23, 2008 - 06:50 am: |

|

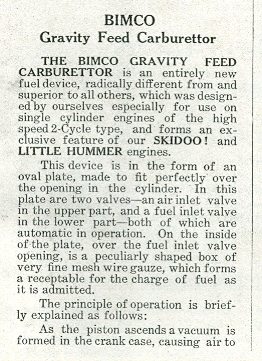

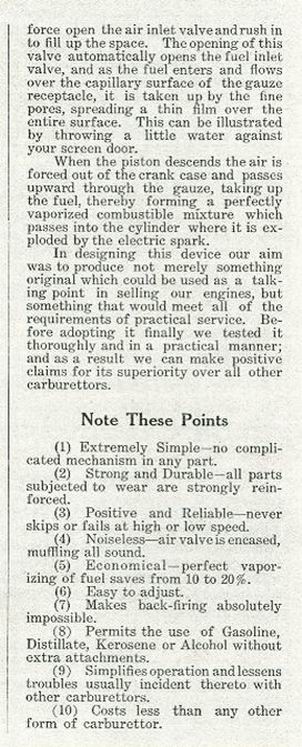

Thanks, Richard you are closing in on the carburetor for the Belle Isle. Note the reference to the "oval plate" in the first sentence in paragraph two of the Bimco write up.

The Belle Isle is the only engine I have ever seen which has the strange vertical diamond, (oval) shaped cast plate over the inlet port. Andrew's Belle Isle is just like mine and years ago I saw another at Zolfo Springs with the same diamond shaped plate. Andrew's had a check valve and Schebler model D as I recall screwed into the 3/4" NPT inlet. I will have to take a couple of close ups of my float feed mixer and try to post it here. The discription of the Bimco carburetor doesn't seem to fit the mixing valve on my Belle Isle.

Another point it think about 30 years ago when Barbara bought the Belle I saw a magazine ad showing the unique diamond shaped casting over the inlet port. The Belle Isle and Little Hummer show pipe thread inlet ports. Will try to get photos today if we get a break in the weather. Either we have drought or flood and at the moment it is flood. Not as bad as those poor folks in the midwest however. |

RichardDurgee

Senior Member

Username: richarddurgee

Post Number: 1727

Registered: 11-2001

| | Posted on Monday, June 23, 2008 - 09:01 am: |

|

*

in the complete price list above notice that a Bradbeer float feed carburetor was used on the twin engine- possible that this carb was used on the singles at a later mfging date ?

Belle Isle Motor Co.first mfgd in 1907, I believe from my notes so far that the engine design was obtained from the Saint Clair Mfging Co. of Detroit,Michigan a true manufacturing co. making the Little Skipper Engine in 1905-07 and selling its inventory to The Gray Hawley Co.in 1908 and the rights to manufacture the engines to The Monarch Tool Co. These engines differ from the Belle isle singles with different carburetion and water/pump timer assembly but can be mistaken very easily for a Belle Isle.

this is a 1911 Belle isle ad and shows part of a float bowl carb ?

Any photos of Belle Isle Engines would be very welcomed !!

* |

Richard A. Day Jr.

Senior Member

Username: richardday

Post Number: 624

Registered: 11-2003

| | Posted on Monday, June 23, 2008 - 06:19 pm: |

|

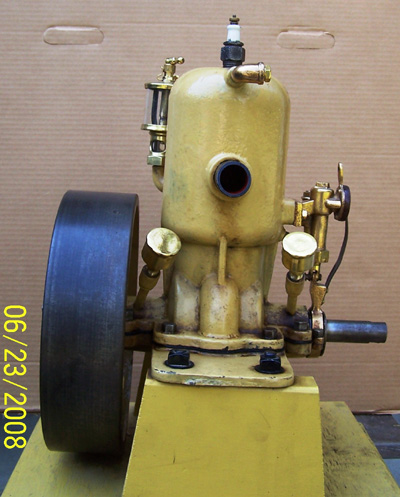

Here are some photos which will give you an idea of the float feed mixing valve.

|

RichardDurgee

Senior Member

Username: richarddurgee

Post Number: 1729

Registered: 11-2001

| | Posted on Monday, June 23, 2008 - 07:23 pm: |

|

*

That is definately a unique Mixer and one I have not seen before !

A scan of U.S patents did find the Bradbeer mentioned above in the Belle isle catalog that was used on their twins in 1907 and its another unique carb but not like the photos above ?? I'll keep looking.

http://www.google.com/patents?id=dQVbAAAAEBAJ&dq=bradbeer+1907

* |

Richard A. Day Jr.

Senior Member

Username: richardday

Post Number: 625

Registered: 11-2003

| | Posted on Monday, June 23, 2008 - 07:37 pm: |

|

One interesting fact I forgot to mention is the thrust bearing in located between the forward face of the crankshaft throw and the forward inside end of the crankshaft bearing. I have never seen this in any other antique marine engine. I wonder if anyone has seen this great idea. Lubricated and protected from the elements. |

Ernie

Senior Member

Username: ernie

Post Number: 835

Registered: 01-2002

| | Posted on Tuesday, June 24, 2008 - 07:58 am: |

|

Some of the Detroit Auto Marine Family had the thrust bearing on the back of the front main. |