| Author |

Message |

Ken Tucker

New member

Username: ktucker8

Post Number: 3

Registered: 07-2006

| | Posted on Monday, July 24, 2006 - 01:31 pm: |

|

I've got a Palmer M-60 in a 34' 70 Columbia I just bought. There is no temp guage in the instrument panel which I find foolish. I noticed there was a temp sender in the Thermostat housing? I am not sure of the size 1/8 thread or 1/4? I am 120 miles from my boat and forgot to pull it and take it with me. Anyone know the size threads for the temp sender so I can get one to replace it before the drive back down this weekend and where to get a temp guage and sender to install?Thanks Ken. |

Eddie Ross

Senior Member

Username: eddie

Post Number: 148

Registered: 04-2003

| | Posted on Monday, July 24, 2006 - 03:49 pm: |

|

You can get a temp. gauge and sender at any good marine store. Match the same brand of both the sender and the guage for compatability. Sorry, can't remember the size. Be careful when replacing sender. Several people wrote in about cracking the housing at the area of the threads. |

Richard A. Day Jr.

Senior Member

Username: richardday

Post Number: 362

Registered: 11-2003

| | Posted on Tuesday, July 25, 2006 - 09:06 pm: |

|

The typical location of the temperature sensor is in the top of the cylinder head flange fitting for the hot water to return to the exhaust manifold or the thermostat housing where one is used.

I am not aware of a temperature sensor in the thermostat housing. Could be, just never run into it before. I wonder if the head air bleed fitting which is often a 1/8"NPT into the thermostat or the exhaust manifold has been plugged and the air bleed removed. If so it should be restored immeadiatly to avoid serious overheating of the cylinder walls. I checked 5 different P-60s and their temperature sensor is a part of a Hex head brass 1/2" NPT, pipe plug. The sensor is apparently a permanent part of the brass plug. I see no way it can be removed and replaced except by replacing the entire plug. The brass plug is marked on the flats 62 AH and N 11 12 V I have no idea what 62 AH or N 11 mean. I assume 12 V means 12 volts which is the typical voltage used in all but the very early P-60, AKA M-60s. Expect that 6 to 12 volt change took place in the late 1950s. Best I can come up with. |

Ken Tucker

Member

Username: ktucker8

Post Number: 4

Registered: 07-2006

| | Posted on Wednesday, July 26, 2006 - 12:55 pm: |

|

What is the air bleed fitting? I don't believe it is on this engine. It looks like there has been head work done but being on a sailboat the last owner must not have run it long wherence no temp guage. I don't like to take chances so I'm putting on a temp gauge.So what is this air bleed valve? Is it just a petcock to bleed air out of the water system on initial startup. I have strictly a raw water system on this engine.Another dumb feature for being in the saltwater of the bay. |

Eddie Ross

Senior Member

Username: eddie

Post Number: 149

Registered: 04-2003

| | Posted on Wednesday, July 26, 2006 - 04:22 pm: |

|

The air bleed is a small hose or tube coming off a 1/8" pipe thread fitting on top off the cylinder head at the forward end. Cylinder heads for the tractor version of the engine do not have a fitting there and if you use a tractor head you should dill and tap a 1/8" pipe thread hole there and put in a fitting.

Richard is concerned that what you refer to as a thermostat housing is NOT a thermostat housing but only a water hose fitting and it would have a place for a sending unit in it. It is located where the thermostat housing would be on a tractor engine. |

Richard A. Day Jr.

Senior Member

Username: richardday

Post Number: 365

Registered: 11-2003

| | Posted on Wednesday, July 26, 2006 - 05:48 pm: |

|

Eddie, I am not confused the hose from the top of the P60 head with the hot water retun to the thermostat housing is on the aft end of the head. Aft from the flywheel end of the engine if the boat has a V drive then the flywheel is aft in the boat not forward. The temp sensor is in in the top of the fitting that the hose to the thermostat connects to. All P-60s AKA M-60 supplied by Palmer have a taped 1/8" pipe thread bronze fitting that connects either with a copper tube or synthetic tube about 1/2" in diaameter to the top of the flywheel end of the exhaust manifold or to the thermostat houseing. This constantly bleeds off any entrained air/steam in the top of the cylinder head. With it pluged or missing the air/steam build up inside the head will force the cooling water down exposing the top of the cylinders to no cooling water and creating a very dangerous situation for the life of the engine. The top of the cylinder inside the head gets red hot and if it is suddendly hit with a gush of cooling water it can crack the inside of the head. The air bleed should be checked at least once a year to make sure it is not plugged and water flows freely. This includes removeing the piping/hose withe the engine running to make sure water comes out of the head. If some one put a tractor head on that is fine as long as they drilled and tapped a 1/8" NPT hole for the air bleed line. If they didn't do it immeadiatly. NuFF said. |

Ken Tucker

Member

Username: ktucker8

Post Number: 5

Registered: 07-2006

| | Posted on Wednesday, July 26, 2006 - 06:29 pm: |

|

Anybody have any pictures of this that I can go by?I will be back down to my boat on Fri night and I will check for this fitting and tube. I recall there being a old 1/8 pipe sender in the "thermostat housing" where the water hose about 3/4 inch heater hose is connected. This is at the front of my engine. The flyweel is at the rear of the boat. I have a Palmer reverse gear driving the shaft so I am looking at this sender at my front of the engine.I appreciate all the help. Thanks Ken. |

Eddie Ross

Senior Member

Username: eddie

Post Number: 151

Registered: 04-2003

| | Posted on Wednesday, July 26, 2006 - 07:30 pm: |

|

That's what I want to make clear. The fitting that looks like a thermostat housing and would be a thermostat housing on a tractor is NOT where the thermostat is on a Palmer. You will find a threaded hole in the fitting for the sender A 7/8" water hose comes off of the fitting. It is at the at the same end as the distributor. I am going by my configuration. If your's is a V-drive forward end of engine may be opposite. |

Lawrence T Wolfe

Senior Member

Username: larry_from_maryland

Post Number: 188

Registered: 07-2003

| | Posted on Wednesday, July 26, 2006 - 09:23 pm: |

|

Is'nt there a picture on oldmarine engine somewhere? Remember the tractors did NOT use a water pump or thermostat. |

Ken Tucker

Member

Username: ktucker8

Post Number: 6

Registered: 07-2006

| | Posted on Wednesday, July 26, 2006 - 09:56 pm: |

|

Thanks Eddie! That is the same configuration I have.And that is the sender I am inqiring about. |

Ernie

Senior Member

Username: ernie

Post Number: 425

Registered: 01-2002

| | Posted on Thursday, July 27, 2006 - 04:18 pm: |

|

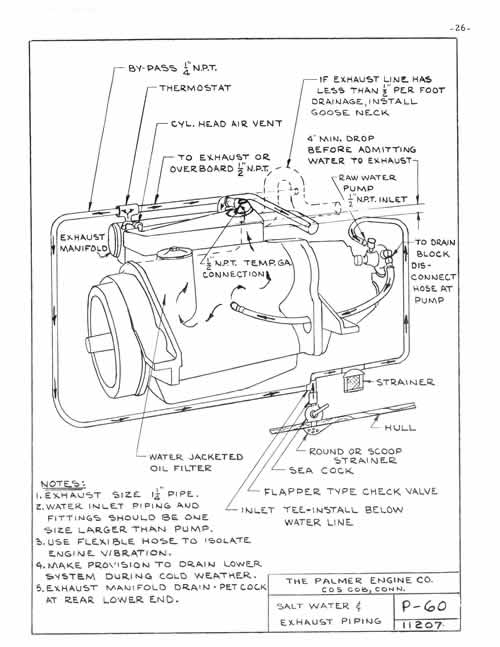

If a picture is worth a thousand words here are 2000. One with thermostat and one without.

Also note where the temp sender is.

|

Ken Tucker

Member

Username: ktucker8

Post Number: 7

Registered: 07-2006

| | Posted on Thursday, July 27, 2006 - 05:09 pm: |

|

Ernie-That is the sender I am inquring about!The Top picture looks like my engine. Not sure what the difference between the two photos are for with and without the thermostat. I don't recall seeing the steam bypass line on top of my engine. If it is not there I will have to figure on where to drill the vent hole in the head. I've got a 1/8 pipe tap no problem but don't want to pull the head to do this. The engine currently runs perfect.Thanks Ken. |

Andrew Menkart

Moderator

Username: andrew

Post Number: 689

Registered: 11-2001

| | Posted on Thursday, July 27, 2006 - 06:17 pm: |

|

|

Eddie Ross

Senior Member

Username: eddie

Post Number: 152

Registered: 04-2003

| | Posted on Thursday, July 27, 2006 - 07:46 pm: |

|

Top picture shows air bleed as approx 5'' copper tube coming from 1/8" brass fitting in head to galvanized pipe elbow where the thermostat housing should be (right side of picture). Sending unit can be seen in water hose fitting (looks like thermostat housing) directly in front of coil and near distributor.

Bottom picture shows air bleed bypass as 1/4 " black hose instead of copper tube coming from fitting in head to what looks like the thermostat unit (upper part of picture slightly left of center) which is connected to exaust manifold. Sending unit also visible in this picture almost center of photo.

Sketch defines air bleed as CLY.HEAD AIR VENT. Threads for sender noted as 1/2" pipe thread which sounds like what I recall. I urge caution with sending unit as several people have broken the cast iron hose fitting. |

Ernie

Senior Member

Username: ernie

Post Number: 426

Registered: 01-2002

| | Posted on Thursday, July 27, 2006 - 08:44 pm: |

|

Ken,

Thermostat is the thing silowetted (spelling) against the white sheet in the bottom pic. The top pic has the water outlet directly out of the manifold to either overboard or to your water injection elbo for a wet exhaust. The vent line doesn't have to be copper. It can be hose as in the lower pic. As to drilling the hole in the head. Just look at the pic and go for it. I believe 1/8th pipe uses a 5/16 drill. Don't worry about the chips as they will eventually end up overboard. The elbow you can drill on your bench in a vise. Personally I would use a cpuple of 1/8 pipe to hose barb fittings with good fuel line for the hose. I seem to remember the temp sender is 1/2 pipe. (I think)

Good luck

E |

Richard A. Day Jr.

Senior Member

Username: richardday

Post Number: 367

Registered: 11-2003

| | Posted on Thursday, July 27, 2006 - 10:04 pm: |

|

Tomorrow I will try to measure an area where it is safe to drill the head without messing up any inside obstructions. Will put it on here tomorrow. I have a head off that will allow me to give ken an area to look to. I wonder what angle in the boat Ken's engine is sitting. Apparently he has a V Drive with the flywheel aft. I cannot believe Palmer shipped P-60s without the air bleed line. Perhaps someone removed it in Kens boat and put in a pipe plug. |

Ken Tucker

Member

Username: ktucker8

Post Number: 8

Registered: 07-2006

| | Posted on Friday, July 28, 2006 - 01:25 pm: |

|

Richard- My engine says it is a M 60. The flywheel is to the rear of the boat and the distributer to the bow. I have a reverse drive on the distributer side. The distributer side of the engine is angled slightly higher to allow clearance for the reverse drive. I am worried that I don't recall seeing the bypass line. I have a 5/16 s copper line and compression fittings with me to take down to the boat tonight.It looks like the head had been removed at some point and time because it has no paint on it while the block and drive are painted blue.If I had to guess it was removed to allow clearance for the new water heater that was replaced in the boat 2 years ago.The only way to remove that water heater which is mounted behind the engine was to pull motor or remove head as far as I can see. I just wonder if they hopefully plugged the vent line. That would be an easy fix. I would presume the vent line should be toward the distributer side since it is elevated higher then the flywheel side to allow steam to vent?Thank you all for the help and advise. the last thing I want to screw up is a perfect running motor. I don't even use the choke to start this engine! Ken |

Eddie Ross

Senior Member

Username: eddie

Post Number: 153

Registered: 04-2003

| | Posted on Friday, July 28, 2006 - 03:28 pm: |

|

The air bleed is to release any possible air pocket. If the water outlet is at the higher end then it would bleed off any air. |

Richard A. Day Jr.

Senior Member

Username: richardday

Post Number: 368

Registered: 11-2003

| | Posted on Friday, July 28, 2006 - 07:46 pm: |

|

If the water outlet on the head is higher than the cylinder head at the flywheel end of the engine Eddie is correct it shoul automatically vent any air or steam. When you say water heater is it a heat exchanger for the engine or a boat water heater for showers etc? What my concern is is the engine fresh water cooled or salt water cooled? It is apparent the head has been replaced and I wonder if the gasket was the tractor gasket which works well with fresh water cooling but will destroy your engine if salt water cooled. For salt water you have to use a compressable copper gasket. Not the steel compressable tractor gasket. |

Ken Tucker

Member

Username: ktucker8

Post Number: 9

Registered: 07-2006

| | Posted on Friday, July 28, 2006 - 07:59 pm: |

|

The water heater is for hot water-shower sink etc. I have no heat exchanger for the engine. the boat is in the San francisco Bay-salt or brine water.I do n ot know if there is a copper head gasket or not but I will try to look.Thanks Ken |

Richard A. Day Jr.

Senior Member

Username: richardday

Post Number: 369

Registered: 11-2003

| | Posted on Saturday, July 29, 2006 - 05:13 pm: |

|

To locate a suitable position for the air bleed hole note the three head bolts closest to the flywheel and oil filter. The two on the right hand end of the head is the area we will work with. The oil filter cover will be just off to the right from the right corner head bolt. Just aft (Aft assumes the engine is not equipped with a V drive and the flywheel is forward in the boat and not aft.) on the oil filter top side of the head will be found a small boss with a 5/16” 18 THD hole. This will be found plugged on a Palmer supplied head. On the tractor head this small boss and tapped hole secures a brace for the governor control rod from the tractor operators position.. It has no function in the marine conversion. It should be plugged for marine applications. Suggest a 3/8” Long 5/16”X 18 THD stainless cap screw with a dab of pipe dope to seal the hole from jacket water leakage. It has nothing to do with the air bleed piping. Just want to alert others that its there and serves no purpose in the marine conversion.

Hopefully we have now located the region where the air bleed line may need to be installed. Take a typical carpenters flexible steel rule and hook the end over the flywheel side of the cylinder head. Measure approximately 7/8” toward the reverse gear of the engine. Draw a sharpie mark parallel to the side of the cylinder head where the tape measure is hooked. Now do the same type measurement from the oil filter side of the head and mark 1”-7/8” from the side of the cylinder head on the oil filter side. This should give you a clear area where there are no hidden protrusions etc. in the water jacket. This aint Rocket Science!!! Palmer practice was to drill a 7/16” hole for tapping with a 1/4" NPT. This permitted inserting a 1/4" X 1/8” brass bushing in the head. The brass bushing permitted annual easy removal of the 1/8” brass EL without disturbing the cast iron to brass seal that over time tends to become very difficult to remove without danger of damage to the cast iron threaded portion. The head cast iron is not all that thick at this location so caution is wise. The head was about 1/8” thick on the unit I measured.

The other end of the air bleed line should be routed to the street EL on top of the exhaust manifold or into the bronze thermostat housing to insure air is vented out the exhaust pipe with cooling water discharge. My point being street ELS are cheap, exhaust manifold are priceless in these day. So don’t go boring into a good manifold and possibly messing it up for good. Tractor heads are a dime a dozen these days. Copper head gaskets for salt water are almost impossible to find. Don’t use the tractor gasket in salt water or you will soon destroy your engine. You may be able to have compressible copper gasket made if you have the pattern for the maker.

Don’t let forward and aft confuse the issue!! Think of the problem from looking at the flywheel end of the engine. no matter how the engine is mounted in the boat.

Hope this blizzard of stuff helps. |

Ken Tucker

Member

Username: ktucker8

Post Number: 10

Registered: 07-2006

| | Posted on Monday, July 31, 2006 - 11:25 am: |

|

Thank you For all the assistance.Without this site I would of had no clue.I found that there was no bleeder line on the engine and the exaust manifold had been plugged.I drilled a hole in the head and tapped the threads and installed the line. Here are the completed repair pictures.I still do not know if there is a copper head gasket-I can't tell if one was used or not. I did run the engine for a couple hours on the bay and she ran 120 Degrees without a problem. Thank you all again for your advise and being kind enough to take the time to help me out.Ken |

Eddie Ross

Senior Member

Username: eddie

Post Number: 154

Registered: 04-2003

| | Posted on Monday, July 31, 2006 - 11:43 am: |

|

My pleasure. |