| Author |

Message |

Arona Man

Visitor

| | Posted on Wednesday, May 11, 2005 - 06:03 pm: |

|

My 14 hp 1968 Osco (Arona/Lombardini)takes in water via a gear-driven (no flexible impeller or thermostat)pump. Although the water output has a temp sender, the water is never warm enough to trigger the gauge which has a minimum reading of 100f. After running the diesel for hours on end the water temp seems (and feels) to be less than 100f, but my oil pressure slowly drops from 50 psi when cold to around 20 psi at idle when hot even though the oil is only slightly warm to the touch and filled to the required level. When I open the engine block drain when the engine is running water spurts out at a good clip so I know the engine is getting some water. In the engine manual it states that the geared water pump is designed to deliver the appropriate amount of water for optimum engine heat. If this is the case, I'm guessing that what my temp sender is reading is the bypass water and not the water that actually went through the engine because when I open the block drain the water coming out is quite warm. My question is how can I rig a temp sender connected to the threaded engine block drain. My concern with that is if I rig a T-fitting out of the block drain with a temp sender on top, I still won't get an accurate reading because if I close the drain valve (which would now be "downstream" of the sender) water will not be constantly flowing past the sender unless I leave the drain valve open allowing salt water into my bilge. Although this engine has never failed (knocking on teak)in 37 years, I'm determined to once and for all get an accurate water temp reading. Any advice would be greatly appreciated. |

chrissmith

Visitor

| | Posted on Wednesday, June 22, 2005 - 02:38 pm: |

|

Hi, I have an Arona AL186mr 10hp single cylinder motor in my 103 yearold Dutch Gaff Cutter. Does anyone know where I could get a new or `secondhand' cylinder head. Also where do I get parts. Thanks for you time. |

mailjohncairnscom

New member

Username: mailjohncairnscom

Post Number: 1

Registered: 06-2005

| | Posted on Saturday, June 25, 2005 - 07:13 pm: |

|

Hi, I have a Arona AL186 engine in my East Coast sloop, can anyone help me find an oil filter for it? John |

andrew

Moderator

Username: andrew

Post Number: 1161

Registered: 11-2001

| | Posted on Sunday, June 26, 2005 - 09:55 am: |

|

It is probably cross referenced to a Fram or other major manufacturer of filters. You need to find the original or cross referenced part number.

You could ask at the following site:

Arona |

Lin Pardey

Visitor

| | Posted on Monday, December 19, 2005 - 08:24 pm: |

|

Hi

I have an Arona 185 deisel which I am told is 10hp in my 110 year old gaff racing sloop. I have the original manual but it does not say what the horspower is, nor at what revs it produces this horsepower. Can anyone give me an answer or source for an answer as the maxprop folks want this to determine pitch of propellor.

You can see pictures of the lovely Thelma who has the engine at www.landlpardey.com, March and April 2005 newsletters. |

andrew

Moderator

Username: andrew

Post Number: 1303

Registered: 11-2001

| | Posted on Tuesday, December 20, 2005 - 09:19 am: |

|

Lin,

How's your Danish? Looks like the 186 (appears similar to the 185) is 11HP at 3000rpm max or 10HP at 2800rpm continuous.

See the pdf manual in Danish with specs here. |

mrjungleberry

Visitor

| | Posted on Sunday, March 05, 2006 - 04:00 am: |

|

hi there one and all

AL 186 Arona marine diesel

has anybody got a copy of the engine @ gearbox manual( Workshop ) available written in the ENGLISH Language

Many thanks,

Laurie |

richardday

Senior Member

Username: richardday

Post Number: 306

Registered: 11-2003

| | Posted on Sunday, March 05, 2006 - 05:47 am: |

|

As a rough estimate for most people the threshold for pain is about 125F. You don't want the salt water temp to go over 143F as salt will percipitate out of the water and totally block up the water passages in the engine. What ever you do don't let the water passages in the cast iron portion of the engine, exhaust manifold etc. dry out as salt imbedded in the iron will expand and destroy the engine. This is an irraversable process once it starts. Filling the cast iron portions of the engine water jacket with auto anti-freeze is a good solution if the engine is going to be drained and vunerable to drying out. You can always recover the anti-freeze and reuse it, |

Blackie Swart

Visitor

| | Posted on Wednesday, April 09, 2008 - 09:02 am: |

|

hi, does anyone know a 2 cylinder, 38hp Arona marine diesel engine? |

KERRY

Visitor

| | Posted on Sunday, June 01, 2008 - 06:04 pm: |

|

I would like to get a workshop manual for the Arona marine diesel AD 290, can any one please advise me?

Regards

Kerry |

KERRY

Visitor

| | Posted on Sunday, June 01, 2008 - 06:12 pm: |

|

I would like to get a workshop manual for the Arona marine diesel AD 290, can any one please advise me?

Regards

Kerry |

Dave Edwards

Visitor

| | Posted on Thursday, September 25, 2008 - 03:36 pm: |

|

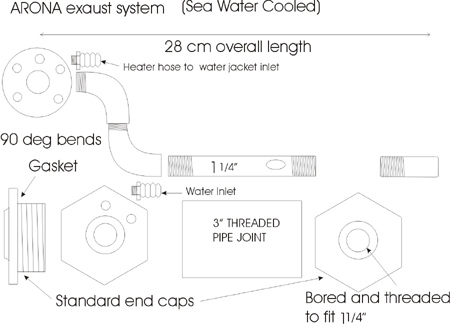

RE: the temp guage problem, Arona had a habit of not exactly measuring the engine temp but sticking a 55C sensor into the exaust manifold. This is then meant to set off the overheat alarm if the manifold goes dry. What's more it works! Home made raw water cooled manifold for my AD 195M} Flange and upper large nut are drilled, tapped and fitted with brass hose outlets joined with heater hose. The big nut is also tapped for the heat sensor. The 1 1/4" pipe goes right through the 3" with a water inlet drilled into the 1 1/4" inside the water jacket.

|

Gordon Weymouth

Visitor

| | Posted on Monday, November 03, 2008 - 04:49 pm: |

|

Dave , your system will not last long in a saltwater environment .

Malleable iron plumbing fittings such as you show above are not suited to raw water cooling and you mention "brass" fittings as well , brass is an alloy of copper and zinc , the zinc is eaten out by salt water VERY quickly and the fitting will fail because of that , not to mention electrolysis between the copper and iron/steel components.

Do yourself a favor and spend a few dollars and make the entire thing from stainless or at least thick walled steam pipe .

Brass skin fittings sink boats , BRONZE is used instead. Bronze is an alloy of copper and tin ( basically ) but in any case , you want to keep the use of dissimilar metals to a minimum because of the electrolysis issue. |

Dave Edwards

Visitor

| | Posted on Wednesday, November 12, 2008 - 03:56 pm: |

|

Thanks for your concern Gordon, but after some 45 years as an engineer you are teaching your granny to suck eggs. we shall no doubt see! I don't know who would make a stainless one for a "few" dollars but good luck if you can get it done! I don't expect this one to last but neither did the original, it had to be repaired after 8 years. |

Willis

Visitor

| | Posted on Tuesday, July 28, 2009 - 05:01 am: |

|

i got a 10 horse power Arona ( thoughts of Steward Turner come to mind ) ,I really could do with new rings for the engine , but can we get them anywhere .

Who still has or makes parts for this engine .

Thanks Willis |

Willis

Visitor

| | Posted on Tuesday, July 28, 2009 - 05:39 am: |

|

Oh and while we are on the subject, I replaced my manifold with stainless , it's not a problem .

The old black iron one had had it's day and I wasn't going to repair that , after a few years all that is left is carbon and you start all over again . After working in boat related engineering for the last 50 , I am afraid my money is on Gordon , I 'll give it 3 to 5 years , but if you don't mind doing the job when it needs doing then it's not a problem . I am lucky ,I have a few friends who let me use their lathe and milling machine :-) and their welder to :-) and what kind of engineer would I be if I couldn't weld s/s and aluminium.

Laters

Willis |

jimdereynier

Member

Username: jimdereynier

Post Number: 18

Registered: 08-2007

| | Posted on Tuesday, July 28, 2009 - 09:38 am: |

|

On Stainless steel exhaust pipe- On my Atkin schooner I have a Sabb 2H. 10 years ago I replaced the exhaust pipe 1-1/2" with scrap yard stainless steel - 304 if my memory is correct. I failed to put in a sacrificial component so now I am faced with cast iron exhaust manifold connection that is about 40% rotted. I screwed a SS nipple into a cast iron flange. Where would you put the sacrificial component- How far away form the engine ? |

Willis

Visitor

| | Posted on Friday, July 31, 2009 - 05:51 am: |

|

On my Arona the anonde is inside the head about 8 inches away at most , maybe less .

It would be better if you can have the whole thing made in s/s . 316 if you can , 304 will do.

its not hard to do a flat plate with the holes in it , a couple of bends and bob is your uncle .

Having a boat , I do do favours to ppl who in turn can do favours to me and if they have a machine shop , so much the better :-).

My earlier reference to black iron is of course ( steampipe) just in case anybody wonders about that , it welds very nicely to cast and makes a good repair medium for cast exhaust pipes and will last quite long , but even with that the day will come when you take it off and tap it with a hammer and it will fall apart , all the iron having been eaten out by the salt.

The fact is , I don't think there is a longterm solution, salt and various metals just don't go together.

Willis |

Willis

Visitor

| | Posted on Friday, July 31, 2009 - 06:05 am: |

|

I had a look at daves draving and noted that all the fittings he uses are standard and are available in S/S .

So if anybody wants to copy that , just get those fittings in s/s then do the same as he did and it should be quite longlasting .

Only problem might be the bends, but you could get standard bends and nipples to join , that would solve the problem and ofcourse Jim might be able to use that method of making an exhaust , just threading and screwing all of it together.

Its a bit of hobby engineering , but if it works who cares and the only cost will be the parts course you can do most of the rest yourself .

Willis |

John Birch

Visitor

| | Posted on Friday, May 07, 2010 - 10:05 am: |

|

Any ideas what this is? |

golfcarmad

Visitor

| | Posted on Friday, June 04, 2010 - 02:46 pm: |

|

John-It's an Arona for sure-could be an AL186 like mine-need more pics to confirm |

tinpusher

New member

Username: tinpusher

Post Number: 1

Registered: 07-2010

| | Posted on Friday, July 09, 2010 - 05:10 am: |

|

Its an AL186 alright, and just like mine except that my alternator is on the LHS. I installed it in a Sadler 25 in 1981 and it is still starting first time and going strong. The single pot shakes it of course and one must tighten up everything regularly. I solved the exhaust manifold rot by taking it off and having a village workshop make me another. Current problem is that under high rev conditions e.g. getting out of the way of a ferryboat the oil cap (which seems to incorporate a pressure or temperature blow-off) sprays oil around, even though the oil level is carefully managed. Is the cap faulty or needing a recalib? You will gather I am no engineer. |

jen & dave

Visitor

| | Posted on Thursday, September 22, 2011 - 05:47 am: |

|

could anyone tell me the correct torque wrench settings for the cylinder head of a single cylinder Arona AD195M diesel have searched the net and found no information. I recently blew a head gasket I have had the head skimmed by 1mm and installed a copper gasket but need the torque wrench setting to finish the job and get back in the water thanks |

johnoxley

Advanced Member

Username: johnoxley

Post Number: 36

Registered: 04-2010

| | Posted on Saturday, September 24, 2011 - 05:20 pm: |

|

Hmm... Cast iron was the material of choice for raw water cooled exhaust manifolds for so many years, but you did have to replace them when they rust wedged apart. OK when the supplier can still supply, or you have a friendly patternmaker and foundry! (Try to use Ni-resist CI) Malleable iron will be OK but will rust eventually. Would use iron, gal or 316 pipe connections instead of brass as the galvanic difference is less. Ordinary Brass dezincifies = dangerous choice as fracture will sink boat. Stainless exhausts are good, but even 316 in certain apps sometimes can't be trusted and can corrode and crack leading to famous quote "In rust we trust". |

Ron Smith

Visitor

| | Posted on Wednesday, November 30, 2011 - 12:33 am: |

|

I have a running Arona AD290 with gearbox and manuals I'd like to sell. Offers? north Queensland

email: [email protected] |

Ron Smith

Visitor

| | Posted on Wednesday, December 14, 2011 - 07:41 pm: |

|

The Arona has been sold thanks. |

david_beasley

New member

Username: david_beasley

Post Number: 1

Registered: 01-2012

| | Posted on Saturday, January 21, 2012 - 05:07 am: |

|

I purchased David Edwards boat in August 2011 ,To day is 21 jan 12 .The exhaust pipe is still holding up and in good shape,When it does give up the parts are cheep and easy found to build a new one. |

Mauro

Visitor

| | Posted on Thursday, February 16, 2012 - 12:49 pm: |

|

Hi everyone, I got an Arona AD182m I need informations about the prestolite starter of this engine.

Someone told me he has found a good near equivalent of this starter from an USA starter site , that had a very good comparison chart of old starters.

Coul anyone tell me something? |