| Author |

Message |

ernie

Senior Member

Username: ernie

Post Number: 580

Registered: 01-2002

| | Posted on Monday, October 10, 2005 - 09:54 am: |

|

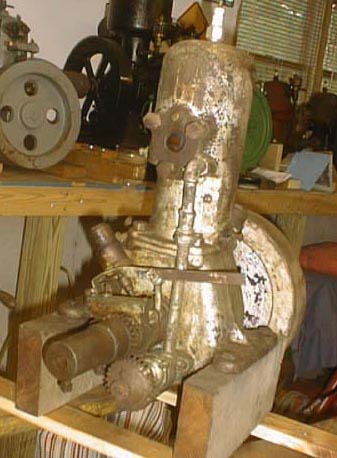

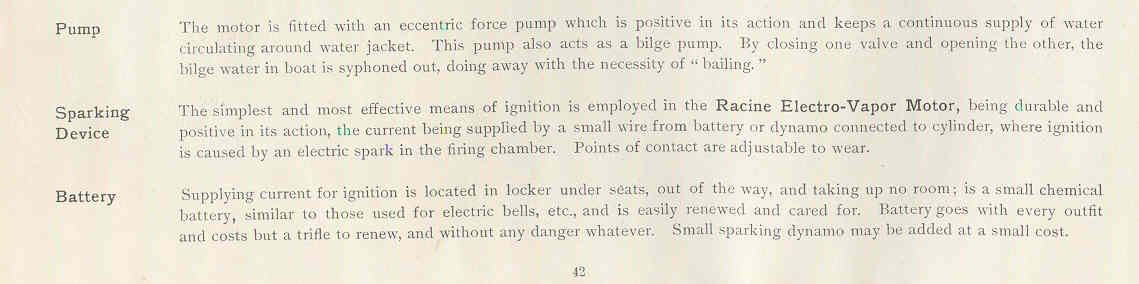

I just picked up this Racine. Is there any info out there? The pics are NOT distorted. It is a tall skinny thing. Flywheel about 12 to 13 inches. Bore about 3 inches. It is a 3 port engine so it didn't neeed a check valve. Wondering what it had for an intake and carb. Also what the exhaust flange and timer handle looked like.

Thanks in advance

Ernie

|

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 866

Registered: 11-2001

| | Posted on Monday, October 10, 2005 - 06:27 pm: |

|

Ernie

There were two Racine Boat Mfg Co's. the oldest was the Racine Wisconsin Co., in 1910 they changed their name to Racine Boat Co.

-

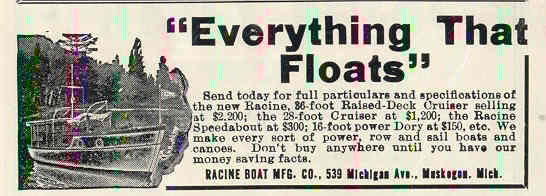

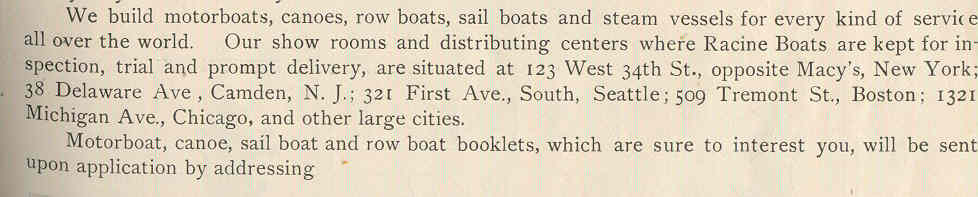

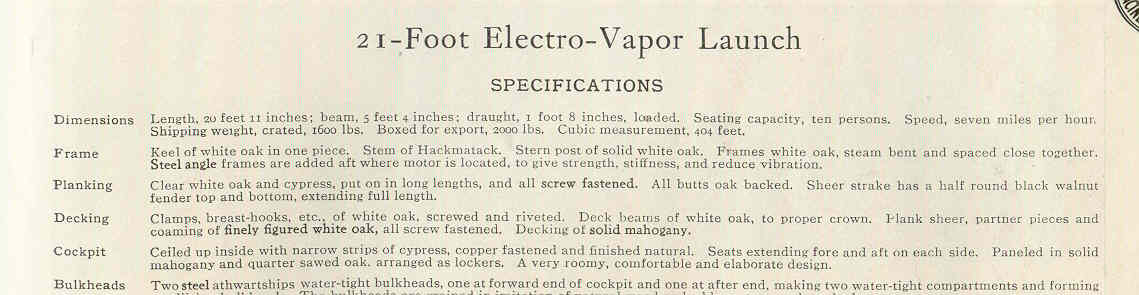

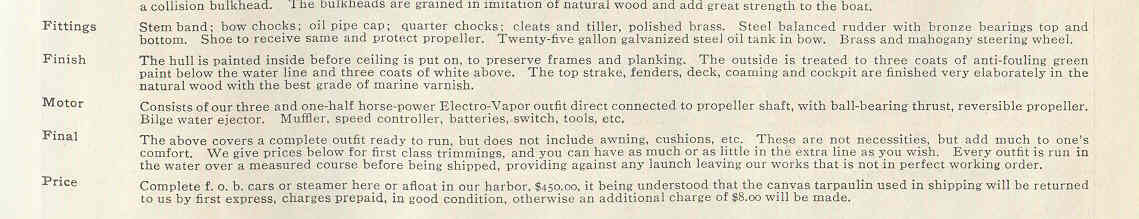

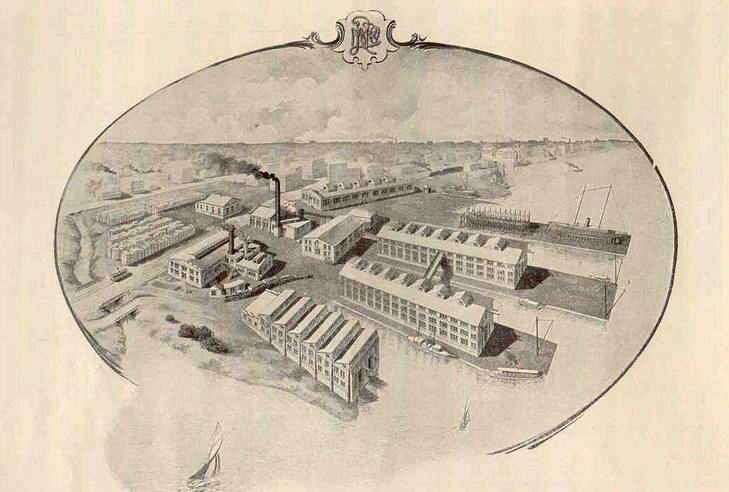

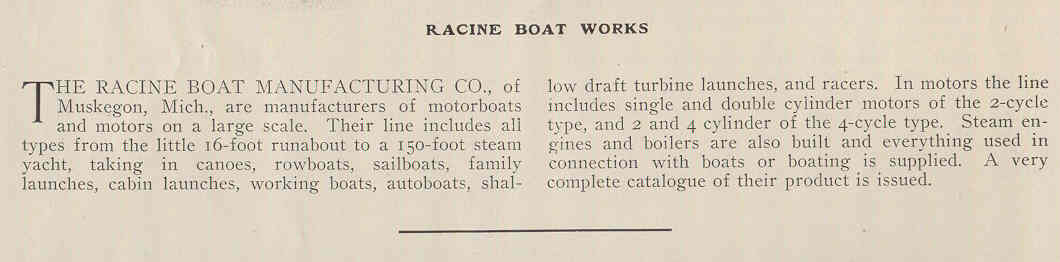

About 1910 the Racine Boat Mfg Co. of Muskegon Michigan published this ad and it stayed the same untill mid 1911 the ads stopped ?

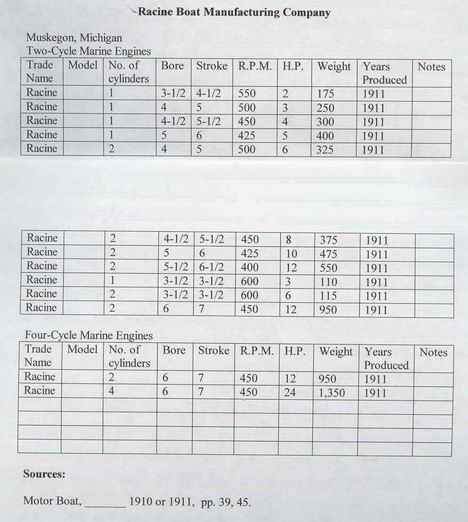

This is from The Michigan Mfgrs List and shows engines mfgd 1910 and 1911 ??

-

Don't know of the connection between these two Co's but must have been with Racine name.

Racine engs were from the original Pierce engine design, and this intake manifold on Keith's Pierce has that same triangular bolt pattern like the one on your Muskegon ??

|

ernie

Senior Member

Username: ernie

Post Number: 583

Registered: 01-2002

| | Posted on Monday, October 10, 2005 - 08:16 pm: |

|

Richard,

Thanks for the info. However the 3 bolt flange on mine is the exhaust. Then intake is down low on the side. Also mine is a 3 port so it would not need the intake chack that is on Keiths engine. From the spec sheet I would guess mine is a 2 hp. |

Scott Peters

Visitor

| | Posted on Tuesday, October 11, 2005 - 07:56 am: |

|

Racine Boat Manufacturing Company moved to Muskegon, Michigan in 1904 after its plant burned in Racine. They were growing rapidly at the time and did not have room to expand at the old site in Racine, so, with the help of some financial incentives from the city of Muskegon, they relocated there, becoming one of the largest boat and engine manufacturers in the state at the turn of the 20th century. They incorporated at Muskegon, Muskegon County on August 1, 1904. The company was located at 59 E. Western Avenue in the city. Officers of the firm included W. J. Reynolds, president and treasurer; J. Harvey McCracken, vice-president; and R. E. Reynolds, secretary. Racine Boat Manufacturing Company filed notice of its dissolution on January 18, 1912, merging with several other firms such as Truscott Boat Manufacturing Co. to form a GM-like conglomerate named National Boat & Engine Company by 1912. When that company failed when the bonds did not sell, they became the Racine-Truscott-Shell Lake Boat Manufacturing Company (bet the secretaries loved typing that one.) That firm closed by 1915. Anyway, that should date the engine to between 1904 and 1912.

Scott |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 867

Registered: 11-2001

| | Posted on Tuesday, October 11, 2005 - 10:17 am: |

|

Scott

Good stuff! Thanks

Had these Mfgrs names but not the dates and tie-together history !

Trying to find a photo ad of the Muskegon Mfgrd engine but no luck so far! |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 868

Registered: 11-2001

| | Posted on Tuesday, October 11, 2005 - 10:55 am: |

|

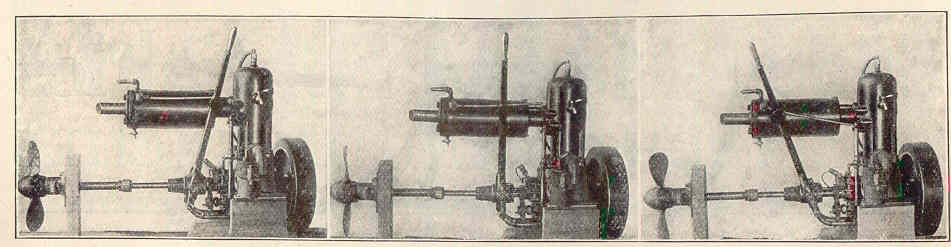

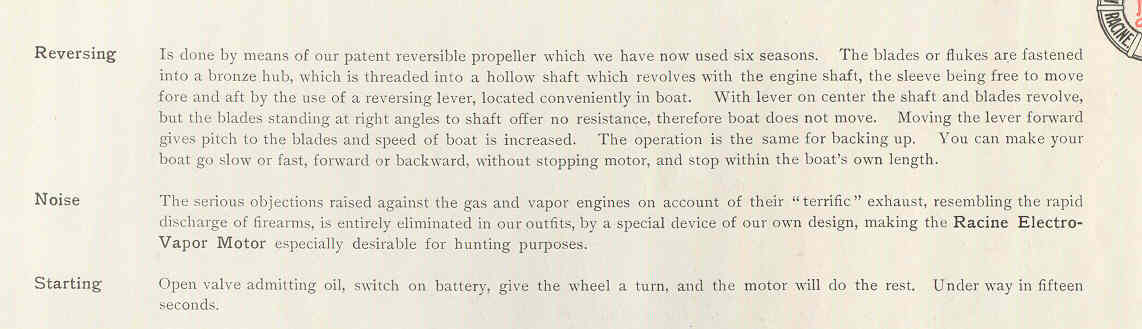

1907 ad

|

ernie

Senior Member

Username: ernie

Post Number: 584

Registered: 01-2002

| | Posted on Tuesday, October 11, 2005 - 01:43 pm: |

|

thanks guys! |

Scott Peters

Visitor

| | Posted on Friday, October 14, 2005 - 07:26 am: |

|

Greetings Ernie, Richard and Friends

Just a bit more on Racine-I was able to check the Michigan Department of Labor annual reports of factory inspections, and between 1904 and 1910 the company employed between 240 and 310 workers. How many specifically were engaged in building engines rather than boats was not indicated, but my guess is somewhere between 50 and 100 people, when you figure their foundry, machine shop, shipping and crating guys, etc. I don't believe I have any Racine catalogs for useful images, but I will dig around to see what I can find.

Good luck,

Scott |

ernie

Senior Member

Username: ernie

Post Number: 586

Registered: 01-2002

| | Posted on Friday, October 14, 2005 - 07:32 am: |

|

I found some refrence to at least one catalogue at a college library in Ann Arbor. However a bit far for me to travel.

I found it by putting "Racine Boat Manufacturing Co" in Google. It was in box 7 under marine |

bruce

Senior Member

Username: bruce

Post Number: 280

Registered: 07-2002

| | Posted on Friday, October 14, 2005 - 08:36 pm: |

|

Heading back to NY from Grand Rapids MI. on Monday, the 24th of OCT. Ernie; What's the name of the Library on the U of M campus?? |

ernie

Senior Member

Username: ernie

Post Number: 588

Registered: 01-2002

| | Posted on Saturday, October 15, 2005 - 09:14 am: |

|

Bruce,

Thanks info below.

http://www.umich.edu/~bhl/bhl/mhchome/catalogs.htm

Bently Historical Library

Commercial Catalogs Collection

1150 Beal Avenue, Ann Arbor

734 764 3482

Michigan Trade Catalogs in the Michigan Historical Collections

Box 7

BOATS, MARINE HARDWARE, AND SUPPLIES

Racine Boat Manufacturing Co., Muskegon, Mich.

The blue book of motor boats. [n.d.]

It looks like there may be a lot of neat Marine stuff here. Gray and Truscott to name a couple.

FROM EAST: I-94 to north on US 23 to Geddes Avenue exit; turn left onto Geddes Avenue. Proceed through six lights (at the intersection with Huron Parkway Geddes Avenue becomes Fuller Road). Immediately after the sixth light, which is at Glazier Way and the V.A. parking structure, turn right onto Beal Avenue. The Bentley Historical Library is the second building on the right. |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 872

Registered: 11-2001

| | Posted on Saturday, October 15, 2005 - 11:15 am: |

|

This article helped sort this out a little more!

http://64.233.161.104/search?q=cache:IwPzwKcfMCkJ:www.wcha.org/wcj/v27_n1/racine .pdf+Racine+Boat+Manufacturing+Company&hl=en |

ernie

Senior Member

Username: ernie

Post Number: 590

Registered: 01-2002

| | Posted on Monday, October 17, 2005 - 09:49 pm: |

|

Now the rubber hits the road, oops thats car stuff.....

Anyway

The tall skinny thing runs. It started 1st turn, kick for those of you that know me.

As to all the history. It really is neat to know the history of the engine mfr. But I really would like a pic or 2 of one of these engines. It would be nice to know what the intake and exhaust manifolds looked like. I can't believe this is the only one in captivity.

Once again thanks in advance

Ernie |

Scott Peters

Visitor

| | Posted on Tuesday, October 18, 2005 - 07:31 am: |

|

Hi Ernie,

I think the Muskegon County Museum would likely have Racine catalogues, photos, and who knows, maybe even an engine. Here is their website for their research department:

http://www.muskegonmuseum.org/research.asp

Give them a call and maybe they can come up with the engine images. I will keep looking on this end. The "7000" serial number on the tag surprises me, but I wonder if it has something to do with the model year of 1907. I know they built a lot of boats, but...

Scott |

ernie

Senior Member

Username: ernie

Post Number: 591

Registered: 01-2002

| | Posted on Tuesday, October 18, 2005 - 08:02 am: |

|

Scott,

Thanks for the info. I will get in contact with them.

I was wondering about the high SN myself.

Maybe the engine SN was the same as the hull SN that it was installed in. So engine SN's could be a lot higher than the actual number produced. |

bruce

Senior Member

Username: bruce

Post Number: 283

Registered: 07-2002

| | Posted on Tuesday, October 18, 2005 - 01:01 pm: |

|

Ernie, Muskegon museum is more accessable for me than Ann Arbor Bently library due to travel constraints(family on board). I'll check out the Muskegon source........ |

ernie

Senior Member

Username: ernie

Post Number: 592

Registered: 01-2002

| | Posted on Tuesday, October 18, 2005 - 08:27 pm: |

|

Bruce,

Thanks, I also sent them a request on thier request form. Lets see what that brings.

Where are you in GR. I used to go to 28th out near the airport a lot |

bruce

Senior Member

Username: bruce

Post Number: 287

Registered: 07-2002

| | Posted on Thursday, October 20, 2005 - 08:18 pm: |

|

Ernie, Visiting my son in Wyoming suburb on the South side- will take 28th st into GR. 28th ST is still a major artery into the city and a major commerce route. I love to watch the Salmon negociate the fish ladder around the Grand River dam in city center this time of year. |

Scott Peters

Visitor

| | Posted on Friday, April 28, 2006 - 11:48 am: |

|

Looks like they produced about 800 engines in 1905 for those of you interested in rarity:

"Muskegon’s Boat Industry

Business is rushing at the Racine Boat Manufacturing Company’s factory at Muskegon and it is working overtime. Eight hundred gas engines will be built this year besides a number of steam engines. The castings for them are being turned out by the foundry with great rapidity.

The Muskegon Steel Boat Company is equally crowded with work."

Michigan Investor, Vol. 3, No. 16, January 21, 1905. p. 2. |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1313

Registered: 11-2001

| | Posted on Tuesday, November 07, 2006 - 09:52 am: |

|

*

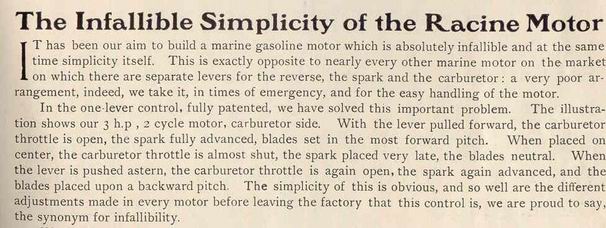

Finally in a special edition December 1905 is a photo of the early Muskegon engine ! how about that patented one lever control system ??

|

ernie

Senior Member

Username: ernie

Post Number: 501

Registered: 01-2002

| | Posted on Wednesday, November 08, 2006 - 07:37 am: |

|

Richard,

Can you send me the engine pics hi res please. I need to enlarge them so I can see what I am missing.

Thanks

Ernie |

keith

Senior Member

Username: keith

Post Number: 159

Registered: 02-2002

| | Posted on Wednesday, November 08, 2006 - 10:59 am: |

|

Here is an early Racine.

Keith |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1315

Registered: 11-2001

| | Posted on Wednesday, November 08, 2006 - 11:28 pm: |

|

*

Keith

Outstanding Old Marine Engine !

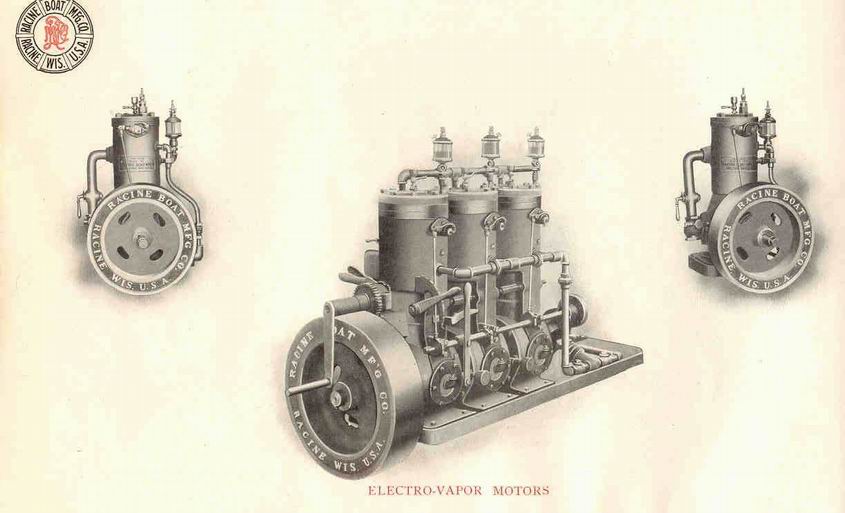

I believe this is one of the very early Racine "Electro Vapor Engines"

Possible to get side and aft photos ?

This is 1902

|

keith

Senior Member

Username: keith

Post Number: 160

Registered: 02-2002

| | Posted on Thursday, November 09, 2006 - 08:20 am: |

|

Richard,

This is the only other picture I have. I will take one of the mixer side this evening. I don't know what is correct on my engine and what is not. Your advertisement will help. Thanks for posting.

|

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1317

Registered: 11-2001

| | Posted on Thursday, November 09, 2006 - 02:23 pm: |

|

*

Keith

I guess your eng has a piston applied igniter ?

the catalog photos are 1902 and have a rod applied igniter, I believe yours is the Older design?? still looking for more info !

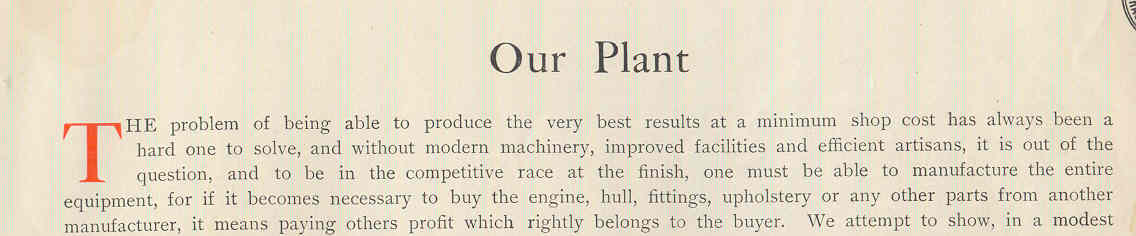

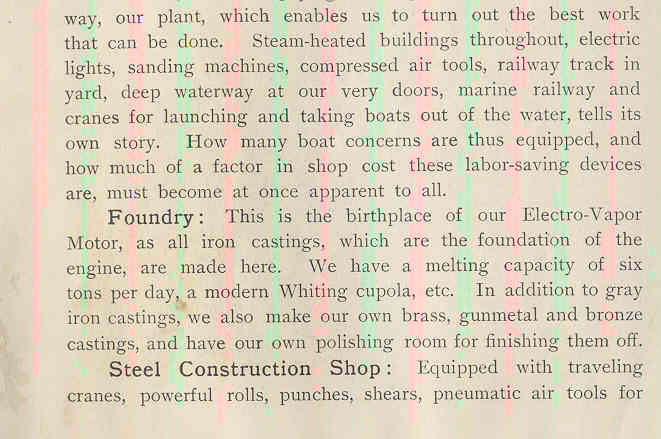

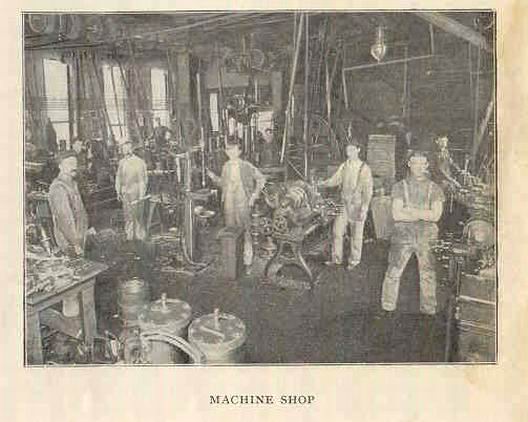

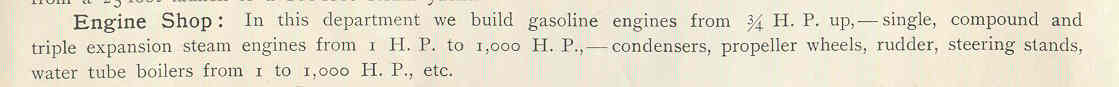

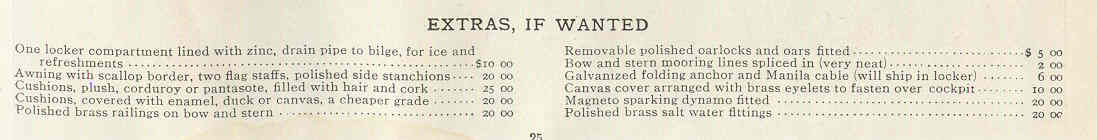

1902 Plant

Machine Shop

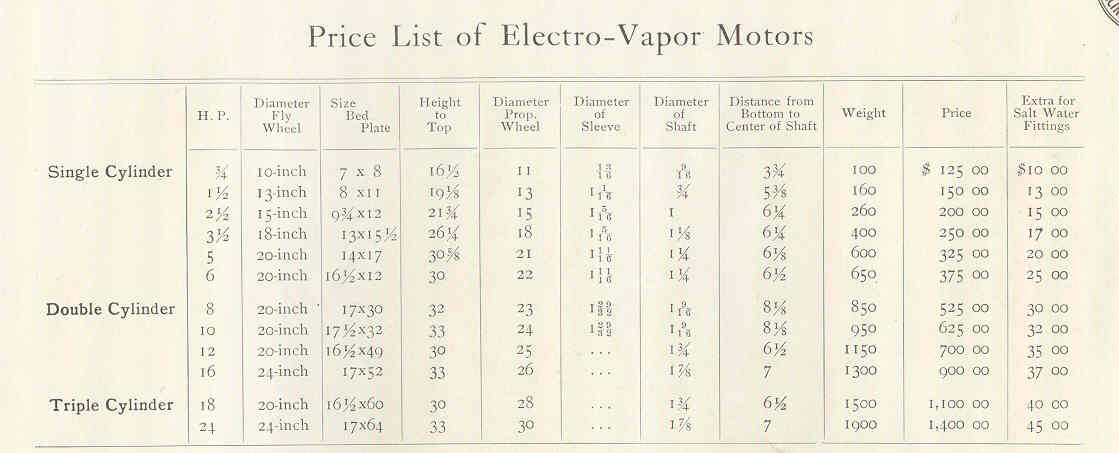

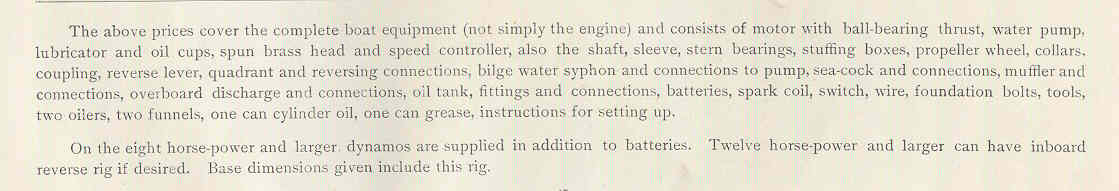

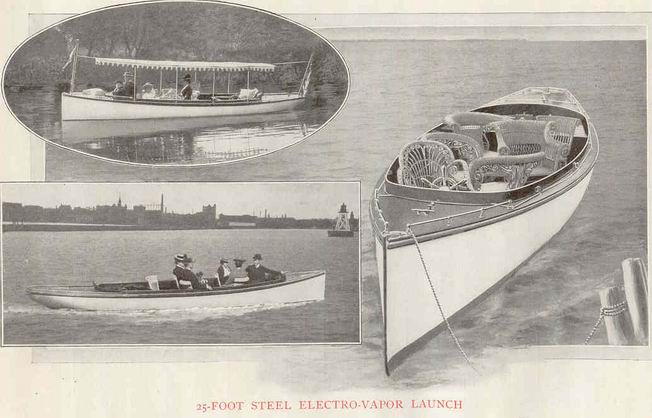

Electro Vapor Motors

Price List

steel Launch

Launch 21ft

|

keith

Senior Member

Username: keith

Post Number: 161

Registered: 02-2002

| | Posted on Thursday, November 09, 2006 - 07:20 pm: |

|

Richard,

The other side.

|

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1322

Registered: 11-2001

| | Posted on Friday, November 10, 2006 - 04:46 pm: |

|

*

Keith

Does the igniter trip when the engine is turned over ? if so, It seems mostly complete and original !

a Great old piece of marine engine history !! |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1324

Registered: 11-2001

| | Posted on Sunday, November 12, 2006 - 12:10 pm: |

|

*

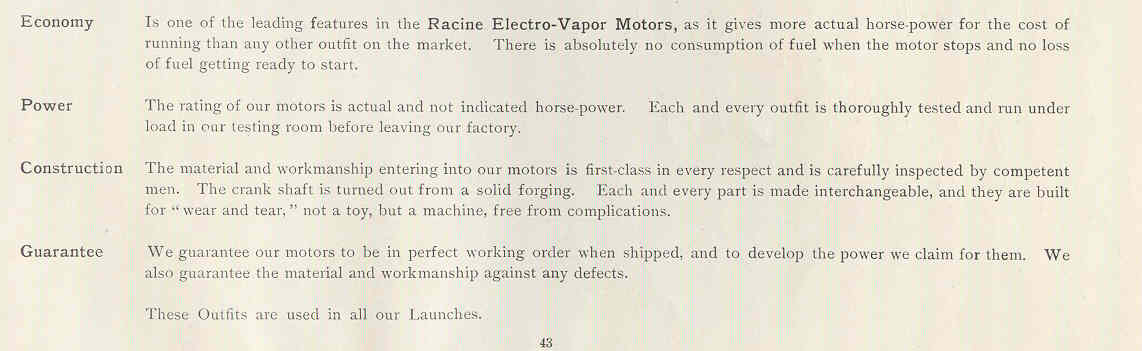

Racine Boat Works 1905

|

keith

Senior Member

Username: keith

Post Number: 163

Registered: 02-2002

| | Posted on Monday, November 13, 2006 - 09:55 am: |

|

Richard,

It is piston trip, but there needs to be something different going on outside the cylinder. If the movable electrode is spring loaded against the fixed electrode, it would be a long cycle on the coil which would tend to get hot and drain the battery. I have a 1898 Fairbanks-Morse flywheel engine that has a piston trip igniter and it has a contact that send current to the coil just prior to breaking. Any thoughts?

Keith

|

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1327

Registered: 11-2001

| | Posted on Monday, November 13, 2006 - 02:58 pm: |

|

*

I'm thinking out loud here!

The external pieces look OK to me, I can see that something in the cylinder is missing and the igniter won't work as it is .

The square raised area on the outer end of the piston deflector is designed to operate a movable arm.

The curved arm I would loosen and slide in a bit and see if it contacts this area of the piston correctly ,it seems to long to be the igniter contact, I would then look closly at wear on the arm to see which side had been in contact with the piston ?

If the wear spot is on the top of the arm as the shiny spot may indicate in the photo then I would

go thru the process to see if the piston is facing the correct way ??

With that info known- - I believe another arm or metal tab will need to be fabricated on the same shaft and attached to the curved piston apply lever that will make contact with the igniter when piston is approaching TDC ??

All input appreciated !! |

keith

Senior Member

Username: keith

Post Number: 164

Registered: 02-2002

| | Posted on Monday, November 13, 2006 - 03:27 pm: |

|

Richard, The piston is in correctly, with the transfer port front and exhaust to the rear. The pad does contact the rotating or movable electrode just prior to top dead center and breaks the contact. With that setup the spring tension would require the points to be normally closed. I don't know if this picture shows it better? It does show the electrodes together and the piston is not yet at top dead center.

???

Keith |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1328

Registered: 11-2001

| | Posted on Monday, November 13, 2006 - 05:55 pm: |

|

*

That photo gives a much better perspective and the mechanism in the cyl does look OK and I see the dilema ! also the sping connected as in first photo would hold contacts open ??? |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1329

Registered: 11-2001

| | Posted on Monday, November 13, 2006 - 07:55 pm: |

|

*

Looking at it again everything is there, the brass spring holder on the movable igniter arm just needs to be turned on the shaft so that the spring holds the movable arm down and in contact with the ignitor. These old make & break systems were made to be in closed position and spark was induced when the circuit was opened - in this case with the piston lifting it up momentarily -- They also used a (LOW TENSION COIL) that was hooked to a 6 volt battery and should'nt over heat - battery should last all season. |

ernie

Senior Member

Username: ernie

Post Number: 508

Registered: 01-2002

| | Posted on Tuesday, November 14, 2006 - 05:41 pm: |

|

OK now to be the devils advocate...

Richard you are correct as to the working of the inside contacts. However as the points in the cylinder are closed except for when the piston is at TDC the current draw was a lot. This is because the points were closed for about 340 to 350 deg of shaft rotation. There may have been a second set of contacts on the crankshaft to close the circuit a few deg before the points in the cylinder were opened by the piston.

It will run the way it is, however it will kill a battery in short order.

Keith is there any indication of a second set of contacts on the crankshaft? |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1331

Registered: 11-2001

| | Posted on Tuesday, November 14, 2006 - 08:26 pm: |

|

*

Ernie thanks for getting in this discussion !

So other than getting the spring to hold the igniter together we are back to square one and Keiths statement that the battery wouldn't last very long this way and something is needed externally is still the question.

Possibly a switch to limit coil dwell to a few degrees before igniter separation ? Keith mentioned his and I have seen them on stationary 4 cycle engs the ones I have seen were connected to a valve. I have spent a lot of time trying to find any info as to the two cycle marine engs but nothing yet . Has anyone ever seen one of these 2 cycle engs with this ignition system ??

I have seen the small suitcase sized battery boxes advertised with banks of batteries, Is this maybe what those old timers used for an afternoon cruise ?? |

searcher

Senior Member

Username: searcher

Post Number: 252

Registered: 10-2004

| | Posted on Tuesday, July 29, 2008 - 11:49 am: |

|

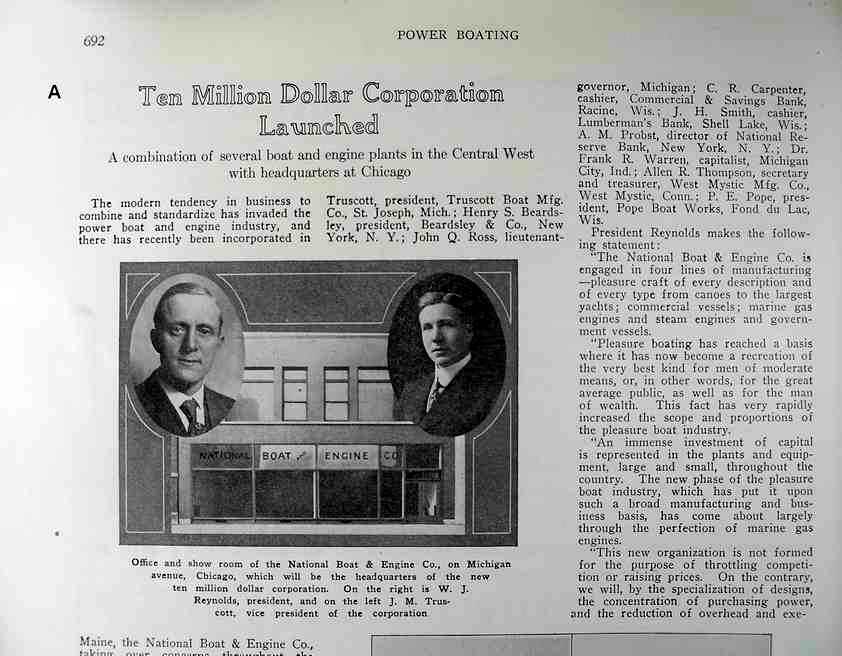

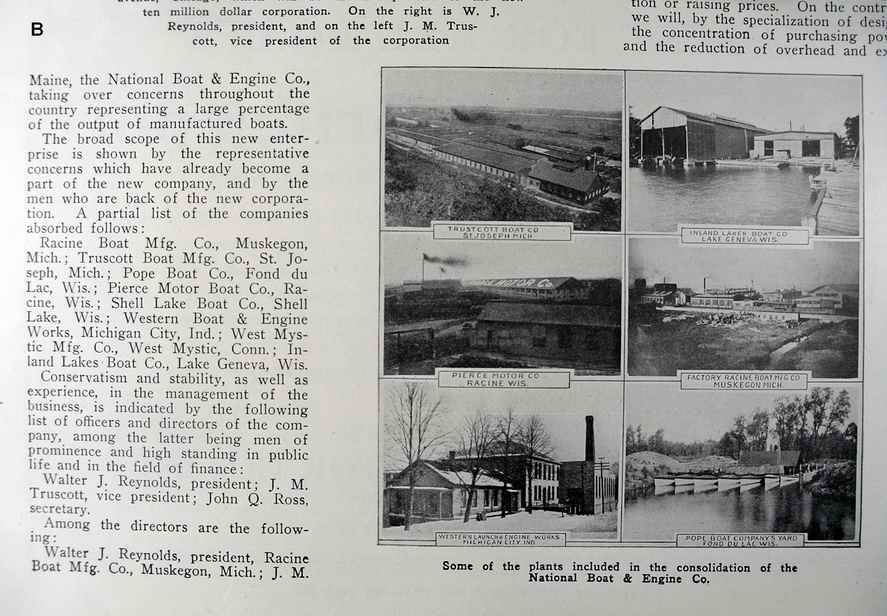

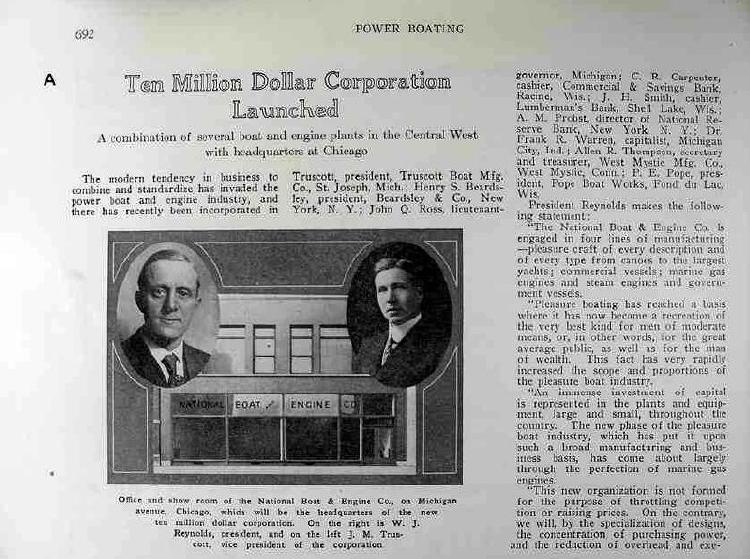

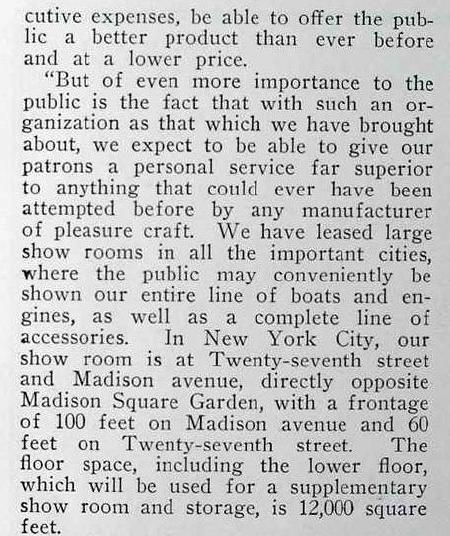

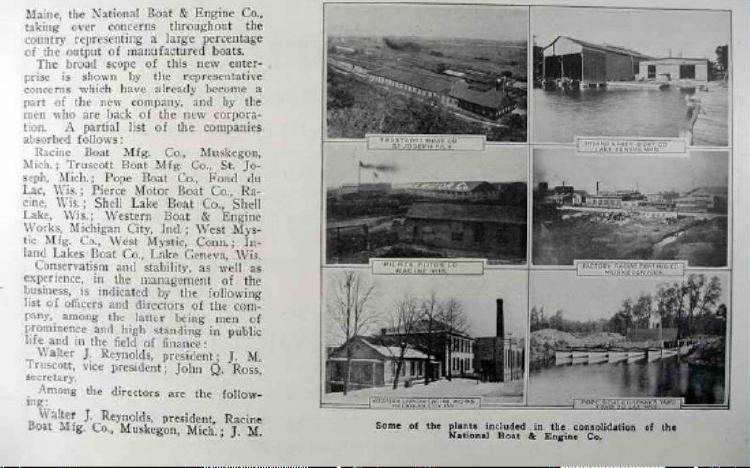

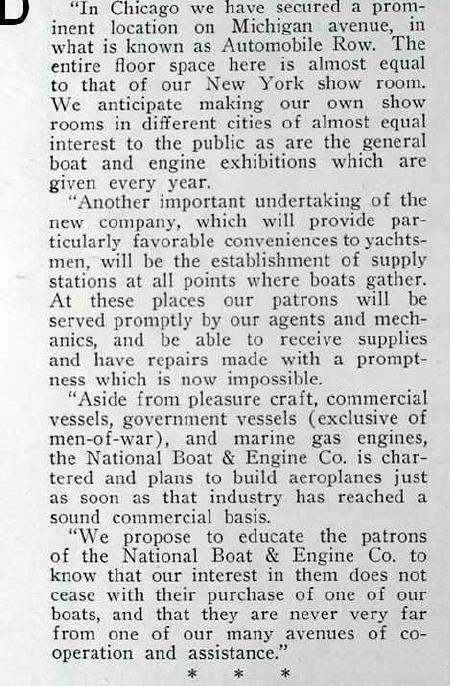

Here is a contemporary (POWER BOATING, December 1910)account of the Racine Boat, Truscott Boat, Pope Boat, Shell Lake Boat, Western Boat and Engine, West Mystic Manufacturing, and Inland Lakes Boat agglomeration that created the National Boat and Engine Company. Note the article relates that this is a "partial list of the companies absorbed"!!!!

I wonder why, given the location of the various companies involved, was NB&E incorporated in the State of Maine as opposed to Wisconsin where most of the companies operated?

The four images are lettered A - D in the upper left corner to help in reassembling them in reading order. I have not yet figured out how to reduce photo images to exactly the same size so that they paste together perfectly. The solution is to buy a good scanner rather than trying to post images from a camera.

|

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1748

Registered: 11-2001

| | Posted on Tuesday, July 29, 2008 - 02:40 pm: |

|

*

Searcher- Good info! Thanks for posting it !

In my lists all these companys mentioned slipped into a hazy history about 1910, some surrived this short lasting conglomerate and some didn't ?

* |

ernie

Senior Member

Username: ernie

Post Number: 857

Registered: 01-2002

| | Posted on Tuesday, July 29, 2008 - 03:03 pm: |

|

Searcher, did you want them formatted like this?

However I had no trouble reading your post. Thanks neat info!

With some screen resolutions you will have to use the horizontal scrol bar.

|

richardday

Senior Member

Username: richardday

Post Number: 638

Registered: 11-2003

| | Posted on Tuesday, July 29, 2008 - 04:49 pm: |

|

Suppose the engine were not 1900 but ca 1892/93. Ray Palmer write how he and Frank looked at other makers available at that time and they all suffered from long dwell which ate up batteries and did not have a quick break to draw a good arc from a large inductor in series with the battery.

Ray devised a two spring igniter which one light pulled the igniter closed but it was immeadiately snapped open by the heavy spring. This action cause a nice arc in the cylinder with minumum battery consumption. Also note the wine bottle engine shape with the bottom of the crankcase a flat mounting plate. By 1900 makers were going to the mountings at the shaft line.

Look at the transfer port set up very similar to the First Palmer with the mixing vale and needle valve in the transfer port along with a butterfly in the transfer port for a throttle. Just a guess but I would assume by 1900 make and break ignition was well enough undertood by all gas engine makers not to have the contacts closed to avoid battery drain. By 1900 makers were casting the transfer port in the engine cylinder wall. Is there any dated material regarding this particular engine model. No control over the arc advance it appears to me. Just thoughts!!! |

trisch

New member

Username: trisch

Post Number: 1

Registered: 08-2009

| | Posted on Wednesday, August 19, 2009 - 03:07 pm: |

|

Hi, I have a Racine Boat Mfg. engine just like Keith Billets. I will try to load photos. I would love to get this engine running. I need a vaporizor, the carb on it isn't original. I think I have the ignition figured out.

Any comments?? Hi Richard Day, I am the guy you met at the Mystic engine show years ago. Sorry I never sent the pics. >>> I tried to do photo.. too big.. will take lower res today

Tom |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 2161

Registered: 11-2001

| | Posted on Sunday, August 30, 2009 - 08:00 pm: |

|

*

Racine

This was a similar discussion back in 2006

Good photos

* |

ernie

Senior Member

Username: ernie

Post Number: 1025

Registered: 01-2002

| | Posted on Sunday, August 30, 2009 - 10:03 pm: |

|

Richard,

Glad you remembered it. Too much good stuff here for any one of us to mentally catalogue it all

Thanks

Ernie |

richardday

Senior Member

Username: richardday

Post Number: 792

Registered: 11-2003

| | Posted on Monday, August 31, 2009 - 09:18 am: |

|

Back to Ernie's point. It would appear the contacts are closed except for the instant at the top of the stroke. Without some external contact this would quickly discharge any battery of the period. By 1902 all the make and break systems understood the need for a coil to generate an arc and limit the current flow. Joe Suydam told me years ago there were two types of small boat generators for Jump spark and Make and Break ignition. They way you could tell the difference was the larger size wire in the armature of the generator for Make and Break. Note the round belt groove in the flywheel. This suggests the ignition system for these engines involved a make and break style generator which would tolerate the very long dwell and produce a good arc at the moment of break. With a coil in the circuit I wonder if the battery switch was one of the BAT-OFF-MAG types. Start on Battery and switch to mag to run. Note also there seems to be timing control of the spark from the crankshaft in later models. Just thinking out loud but food for thought. |

trisch

New member

Username: trisch

Post Number: 2

Registered: 08-2009

| | Posted on Monday, August 31, 2009 - 05:21 pm: |

|

Hi, So I think I figured out the photos. I made a curved lever and made a "CAM" instead of the original igniter "NUT". I can now control the advance. I don't know what to do about draining the battery. There just doesn't seem to be any evidence of any kind of interrupt switch. |

trisch

New member

Username: trisch

Post Number: 3

Registered: 08-2009

| | Posted on Monday, August 31, 2009 - 05:23 pm: |

|

more photos |

trisch

Member

Username: trisch

Post Number: 4

Registered: 08-2009

| | Posted on Monday, August 31, 2009 - 05:30 pm: |

|

There is a number stamped in the top of the piston along with the letters RBMCO. This coincides with the number on the transom of the 15 ft launch that the engine came out of. Cool eh ! |

richardday

Senior Member

Username: richardday

Post Number: 793

Registered: 11-2003

| | Posted on Monday, August 31, 2009 - 05:31 pm: |

|

Seems to me if the cam were insulated with mica then there would be no current flow except at the moment of contact with the piston. |

ernie

Senior Member

Username: ernie

Post Number: 1026

Registered: 01-2002

| | Posted on Monday, August 31, 2009 - 06:14 pm: |

|

There are 2 basic types of piston trip ignitors

With one type (NO) open contact piston trip ignitor there is no current flow untill the piston contacts the insulated arm. This is good as you won't need a second contact to turn on the coil to save battery life. However the down side is that you can never have any spark advance as the piston makes contact on the upstroke and breaks on the down stroke so the best you can get is close to just after tdc.

With the other type of piston trip ignitor which is a closed contact (NC) that the piston hits and opens the circuit. If this style isn't powered by a low tension mag it will need a secondary contact to turn on the coil to save battery life.

This type can have advance but no retard as the piston breaks the circuit on the way up to tdc.

But then again any garden variety 2 stroke make and break engine can have only advance unless it isn't timed symetrically. Meaning the cam or encectric that operates the ignitor is centered at tdc. You can ofset the cam one way or the other to give advance (lots) in one direction and have retard (some) in the other direction.

This engine appears to be the NC or closed type so it will need another contact on the crankshaft ot a low tension mag.

Dick, If the cam is insulated current will still flow most of the time as the points are normally closed (NC) Currnet would just not be depandant on engine ground as you would basically have a single pole single throw switch insulated from the block. |

richardday

Senior Member

Username: richardday

Post Number: 794

Registered: 11-2003

| | Posted on Tuesday, September 01, 2009 - 07:59 am: |

|

You are right Ernie with regard to current flow. Why do I think the cam that adjusted the advance retard must have been insulated. I bet a close examination of the brass fitting holding the timing regulator would have to be insulated but like any of the Make and break igniters could be rotated to change the advance retard. |

trisch

Member

Username: trisch

Post Number: 5

Registered: 08-2009

| | Posted on Thursday, September 03, 2009 - 03:05 pm: |

|

I'm not sure if my math is right but if an engine is running at 500 RPM then the piston is opening the tripper about 8 times per second. It seems to me that even if you had a way to turn off the current flow for say half of each stroke, the current would still be flowing most of the time anyway. The current flow stops at TDC for almost as long as it is on while the piston travels from after TDC to BTDC. Does this make any sense?? |

trisch

Member

Username: trisch

Post Number: 6

Registered: 08-2009

| | Posted on Thursday, September 03, 2009 - 03:34 pm: |

|

Please take a look at my #3 post on August 31.

The nut to the right is live and insulated from the

block. The block is the ground. I made a cam to

replace the nut so that by turning the "cam nut"

I think I can adjust the timing. Do you think

this will work? |

richardday

Senior Member

Username: richardday

Post Number: 796

Registered: 11-2003

| | Posted on Thursday, September 03, 2009 - 08:07 pm: |

|

I think you can adjust the timing but wonder how much control you will have I tend to agree with Ernie on that point. I do think the round belt groove in the flywhee suggests the low tension make and break magneto was intended as the power souce. Don't have any idea if rocking the flywheel would generate enough current to start the engine. My guess is a batteryy was in the loop with a transfer knife switch but that is pure guess work. Note in later engines they seem to control the spark from the crankshaft via a lay shaft!! |

ernie

Senior Member

Username: ernie

Post Number: 1028

Registered: 01-2002

| | Posted on Friday, September 04, 2009 - 11:49 am: |

|

As to running at 500 rpm you won't want to be around it at that speed. The Gray in my boat spends most of it's time at about 250 rpm or slower.

Also this type of ignitor is very and I stress very inefficient. The arc you get will be yellow and slow. A hammer break ignitor has a bright blue spark that is very fast and painfull to watch. One may think the piston hitting it is quick enough to break the circuit fast enough to have a good arc. It isn't. Hook it up and watch what what happens. This is the reason that the "hammer break" ignitor was designed.

Most old engines with ignitors use a hammer break ignitor. It is also the reason why most of these old engines with piston trip ignitors were retrofitted with a spark plug.

I had an engine that was originally manufactured with a piston trip ignitor. I re created the parts and put it together as it was manufactured. It ran so poorly that I eventually went back to a spark plug. It ran good again. This was an NC ignitor like yours and it had a second contact on the crankshaft to turn the circuit on. Also I only went back to the spark plug after lots of adjusting and expirementing. And rocking the flywheel would not start the engine. Also the length of the lever has a lot to do with the speed of the break. The length of the arm on most hammer break ignitors is about 1/2 inch.

Hope this helps

Ernie |

frank_petran

Senior Member

Username: frank_petran

Post Number: 121

Registered: 05-2009

| | Posted on Friday, September 24, 2010 - 09:11 pm: |

|

I am looking for an early Pierce/Racine or Racine engine (made in Racine) in the 1 to 3 hp range. I can be reached via email or phone (262-284-3650.

Thanks. Frank |

Edward Dake

Visitor

| | Posted on Saturday, October 29, 2011 - 08:41 am: |

|

The Muskegon Heritage Museum is looking for a small Racine Engine to be included in our "Made in Muskegon" exhibit for 2012. If you know of anyone that would lend or donate and engine let us know.

[email protected] |