| Author |

Message |

RichardDurgee

Senior Member

Username: richarddurgee

Post Number: 1262

Registered: 11-2001

| | Posted on Wednesday, October 18, 2006 - 12:54 am: |

|

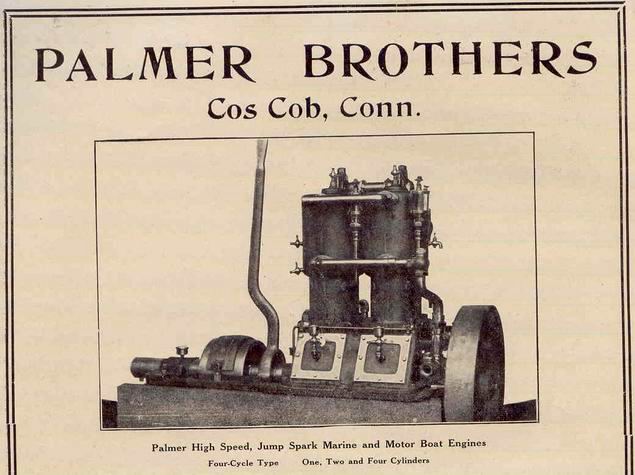

Palmer AD 1905

|

Richard A. Day Jr.

Senior Member

Username: richardday

Post Number: 401

Registered: 11-2003

| | Posted on Wednesday, October 18, 2006 - 09:02 pm: |

|

Richard, There is no three port engine shown. Palmer also didn't always show an engine exactly as it was in reality. We know that the 1907 catalog shows the O,P and Q with a two port base yet it is talking about the valveless 1905 two cycle motor. I have a three port Q-1 with out the boss drilled and tapped for the intake check valve and I have a Q-1 with without the boss and it is also a true three port engine. We also know there are a few two port Model Qs still around. We know from the 1905 catalog they were bringing out a three port engine. My guess is they made the original Q as a two port and later converted to a three port simply by not machining the inlet port in the upper half of the crankcase. Still later they redid the upper half of the crankcase and removed the boss for the inlet check. In any case the new three port cylinder would bolt right up to all three versions of the upper half of the crankcase.

We also know about 1920 they widened the base of the Q to give wider support between the engine beds and they omitted the bosses for the hold down lag bolts that had been off center drilled on earlier bases to gain approx 1 inch wider engine bed mounting.

We know that the first photos of the YT show an engine with the exhaust port was never never made with a pipe boss instead of a bolt on flange. Or the priming cup was never located in the upper starboard side of the water jacket. Henry Zerbarini laughed when I showed him the picture of YT of 1921 and 1947. He started there in 1922 and he said they simply didn't make that engine as they firmly believed in bolt on flanges to protect cylinders from damage when pipe rusted into a boss on a cylinder. He also pointed out that the priming cup would have had to penetrate the water jacket in that location.

Raynal Bolling told me often when they were bringing a new model on stream often the engines they took to the boat shows had wooden parts to show what the engine would look like but had not yet been finished. They didn't make a practice of telling the potential customer that the parts were mockups I might add.

I try to come up with enough photos over a long enough period so I can be reasonably sure that the photos are probably as close to as built as we will ever know. Thanks for posting the photos. Incidentally the model with the reverse gear is an L or M Wish I could explaine the strange cylinder on M that Steve Craig down in AU has. Or for that matter the strange cylinder that Allan Roney in Brisbane AU has on his NL-2. Please keep the photos coming. |

RichardDurgee

Senior Member

Username: richarddurgee

Post Number: 1269

Registered: 11-2001

| | Posted on Thursday, October 19, 2006 - 07:26 am: |

|

Dick -- Great info !

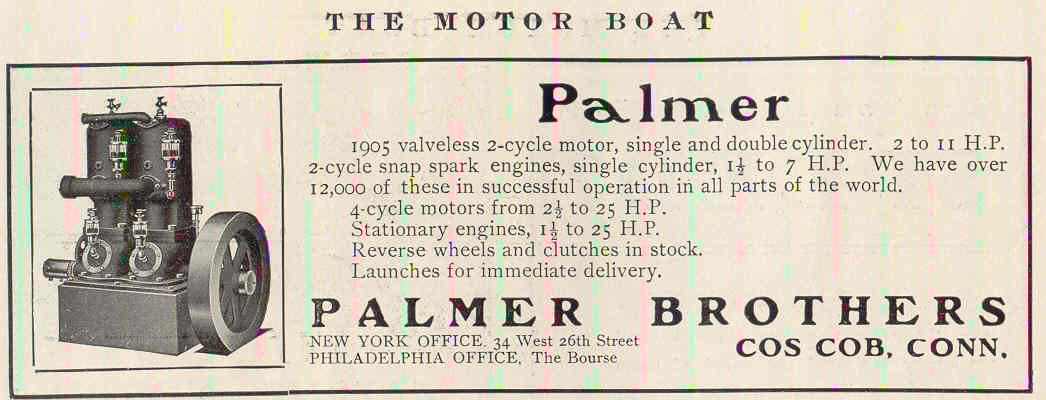

This was the predominant Palmer ad in Motor Boat in 1905 !

Those oilers on the inspection plates remind me of the Latrop oilers, but they had plungers.

|

Ernie

Senior Member

Username: ernie

Post Number: 478

Registered: 01-2002

| | Posted on Thursday, October 19, 2006 - 07:56 am: |

|

Richard,

To add to Dick's comments the first picture shows a B,C,D,E series engine and the add says "no check valves are used on this on this motor" We know that there were none of this series of engines built as 3 ports. All of them used a check valve between the carb/mixer and the crankcase. |

Richard A. Day Jr.

Senior Member

Username: richardday

Post Number: 402

Registered: 11-2003

| | Posted on Thursday, October 19, 2006 - 09:40 am: |

|

Ernie's point is well taken you could read that add as applying to the B,C,D&E models all of which were always 2 port. It is also interesting in the lower add that the flywheel is shown as six spoke in 1905 but they continued to make engines with 5 spoke flywheels as late as 1910/12.

I have often wondered if the six spoke really took off as the way the foundry worker laid out the spokes was to have a single wooden spoke and they simply laid the spoke three times in the sand to create the six spokes. I don't remember exactly who told me that but it sounds very reasonable. Perhaps someone else can offer a different explantion. I do think it came from Henry Zerbarini who worked for Palmer from 1922-1968. Henry was "chief mechanic" and very familiar with all the operations of the plant. He also stamped the serial numbers at final inspection for most of his career. It was a matter of great pride to him that he could reject an engine as not meeting the performance in final test he expected. A very interesting man to talk with. Now unfortunately long deceased. |