| Author |

Message |

clockstopper

New member

Username: clockstopper

Post Number: 1

Registered: 01-2005

| | Posted on Monday, January 03, 2005 - 12:24 pm: |

|

not much with internet, glad i found you guys!. have original 3 cyl, as i can tell, missing only splash covers and orig carb, has stromberg now. solid flywheel, brass waterjackets. complete with dist cap and rotor intact!. appears to not have been apart, in my family a long time. anxious to know more, its a job i'll get to this year, any other 3 cyls out there ?. any pics or info would help, Thank You, Mike |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 693

Registered: 11-2001

| | Posted on Monday, January 03, 2005 - 08:47 pm: |

|

Mike

Brass Waterjackets, This may not be a Dunn Engine ! Possible to e-mail a few photos,Will try to get some information on it !

E-mail photos to me and I will post them here, if that will help.

[email protected] |

andrew

Moderator

Username: andrew

Post Number: 1003

Registered: 11-2001

| | Posted on Tuesday, January 04, 2005 - 01:39 pm: |

|

Mike,

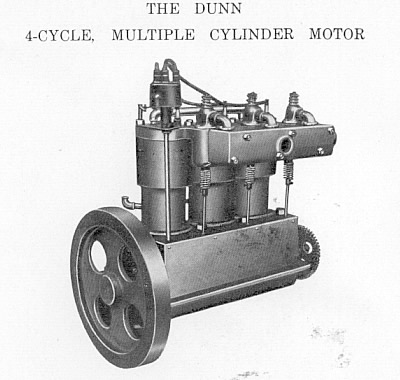

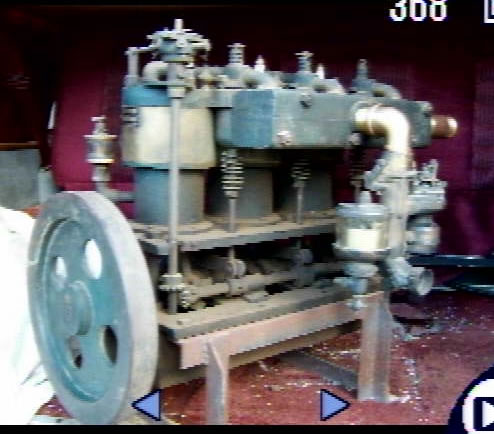

I sent your this picture before... does it look like this...?

|

bill

New member

Username: bill

Post Number: 1

Registered: 03-2005

| | Posted on Monday, March 07, 2005 - 09:50 pm: |

|

I am restoring a Dunn 3 Cyl 6Hp engine that fits the above picture and also has brass water jackets. The tag is still on it so am sure it is a Dunn.

The engine was underwater for many years and is missing several parts. There are many similarities to the 2 cyl restoration but also a number of differences. Missing are the splash panels, mixer, distributor and cam gear. It took over a year to get the engine apart but things are mostly cleaned up and I am starting to put things back together.

I hope you will forgive the many questions I have; any that can answer would be greatly appreciated.

Cam gear:

the pictures give me a good idea of what the gear looked like and clearly it should have double the number of teeth found on the crank gear but:

- of what material is the cam gear made?

- am I correct to assume there is a boss on both sides of the gear; one to ride against the cam shaft rear support and one to take the pin which secures it to the cam shaft?

- have you heard of any of these being for sale or where I can get a blank to make one?

Splash Panels

- Are the ones pictured original? I note the ends are open and was wondering if that is normal?

Mixer

- please advise the throat diameter of your Schebler. I have a few spares but do not see a need for one as large as the 1.5" pipe opening in the maniford.

Distributor

- I am on the prowl for one of these if anyone has any ideas where one might be found? In the meantime, I plan to adapt a distributor from a three cylinder Firefly. Think I can do this without making any changes to brackets so it can be put back to original later.

- Are there a set of contacts for primary power in the distributor or just the rotor and riders to distribute the high tension? If not, how do you turn power on/off to your buzz coil. Also a little confused by the number of wires running to the battery box on the two cylinder restoration. Can the restorer explain how ignition system was wired?

Screws/Washers

- I noticed square head screws on your main bearing caps of the two cylinder restoration. Mine are high profile hex head but have square head screws on the rod bearing caps. Real question is there lock or flat washers under any of your screws? I am a little concerned that there seem no real method to keep the bearing cap screws from loosening off. Also, is there washers or spacers of any type between the cam followers and the pivot points on top of the main bearing caps?

Lubrication

- I see that there are grease cups on all the main bearings of the two cylinder restoration. My engine has one only on the main bearing cap at the flywheel end. The other main bearing caps are not even drilled with an oil hole. Did the two cylinder engine have three grease cups or sere they added?

- There is also no grease/oil arrangements for the connecting rod bearings on my engine. Are others the same?

- One of the posts mentioned that oil was poured into the engine base (to lubricate rod bearings and wrist pins, I assume). Was this simply because it seems like a good idea or has anyoine seen an owners/operators manual for one of these engines? Sure would be nice to find such a manual! Does the oil splash much when the engine is running?

Other

Noticed the two cylinder restoration has painted water jackets. Mine are brass; is that normal?

Found a bit of original paint on the inside of the flywheel near the hub and have tried to match that. It is very similar to the scrapings shown for the two cylinder engine but a bit darker. I like the colour of the two cylinder engine but am committed at this point.

The two cylinder is a great looking engine; hope mine turns out as well.

Again, sorry for the length of this post and thanks for any help you may be able to give.

Bill |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 724

Registered: 11-2001

| | Posted on Wednesday, March 09, 2005 - 07:13 am: |

|

Bill

Go to search and type in Dunn, Some info there.

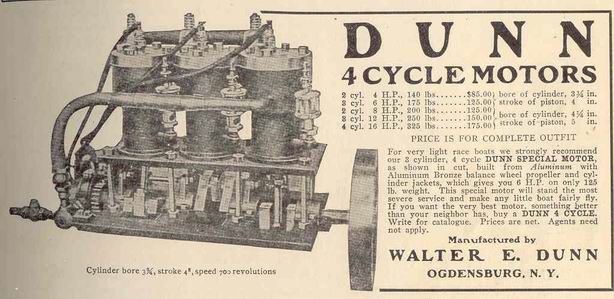

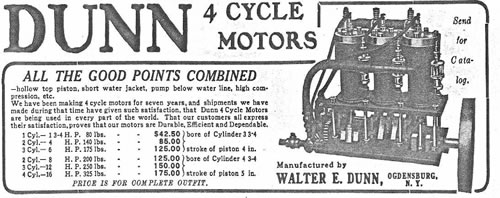

Two three cyl Dunn's on web site here both with brass water jackets, would think that they were factory standard or an option on these engines ? I have not seen reference to them in any of Dunns old catalogs or ads !

Walter Dunn made engs from 1902 -1927 the catalogs and magazine ads seem to be prior to WWI, any catalogs in 1920's out there ?

A unique and eye catching old marine engine to restore, possible to post photos ? If difficulty to post photos email to me and I will post them here and scan what 3 cylinder Dunn info I have to you. Keep us posted on progress >

[email protected] |

thomas

Senior Member

Username: thomas

Post Number: 251

Registered: 07-2002

| | Posted on Wednesday, March 09, 2005 - 11:50 am: |

|

Bill,

I wrote out two pages of answers to your questions but somehow, my webmail ate everything

except the first line. Try calling my cell day time 607-727-9943

I will answer your questions if I can.

Tom |

thomas

Senior Member

Username: thomas

Post Number: 252

Registered: 07-2002

| | Posted on Thursday, March 10, 2005 - 12:42 pm: |

|

Bill,

I will retry the answers to your questions on the OME website:

First I want to tell you how much I wish I had found a BRASS jacket 3 cylinder Dunn!!

It must be the only one

left!! I hope it turns out perfect. (But, if you ever get tired of looking at it

{blah, blah, blah-you know the rest}

My engine, as I got it, had been used almost up to the time it was scraped. I'm

pretty sure it had been rebuilt

(main bearings cut and new Babbitt poured) on the lower end in it's recent past

(which could have been during the depression for all I know). None of the fasteners

have lock washers. What I did all through the engine was to use Loktite "threadlocker".

I realize it makes for a bit of difficulty if something needs to be readjusted but

I was trying to do all the adjusting as I went along from bottom to top and, as

it turned out, I only had to remove some water pump fittings (yes, I locktited them

also). The small square headed bolts that hold the cylinders to the upper base plate

are a good example of why I used the threadlocker: if one if them loosens up the

first time you will notice it is when the bolt falls into the crank area and bangs

around until it (hopefully ) ends up in a crank well out of harms way.

The cast iron cam gear (the gear on the crank shaft is brass) has about a 1/4"

boss on the forward edge that does "rub" against the aft end of the cam

bearing. the adjustment of the camshaft has to be done in two ways.

First, I had to cut some brass shims (trial & error as to thickness) to fit

between the cam bearings and the crankcase so that when the bolts were tightened

there was no binding of the camshaft itself. (as an aside, I replaced those slotted

head screws with the same size but in Stainless). Second, you have to slide the

cam bearings fore & aft within the limits of their screw holes so that the rear

end of the rear bearing and the front end of the front bearing take up the slack

and the camshaft has minimal fore & aft play and does not bind. It took a bit

of tightening and retightening to get mine right. (I did not locktite until all

was right: I then removed and replaced

one screw at a time with the sealer.

Are you missing the cam gear??

My Schebler is not the 1.5" as you figured. I think it's a 3/4" but I'll

check. (forgot to do last eve)

As far as I know, the side splash panels on mine are original. They look crude but

so much of the Dunn is crude looking right from the factory. The 1915-16 literature

showing pretty much my engine, shows what appear to be galvanized steel sides. My

sides are galvanized and show well worn spots and had lots of hard grease buildup

inside in line with the throws. There were no end panels. They mention the panels

on the earlier (1911) engines being aluminum but they still only show two side

panels.

The only engine that they state has oil in the crankcase is the all enclosed crankcase

one cylinder. It used

about 1/2 pint. I just figured that they HAD to put some oil in the wells to make

it work. I put in oil up to the bottom of the rod cap screws. The drip oilers have

to be the kind with check balls and relief tubes and set to drip

about once every 2 seconds. The oil lubes the rings on the way down the cylinder

and then hits the rotating crank

throw right by the corner of the rod and the throw bearing. This additional spray

of oil coats the wrist pin area

and I took lots of pics right after I first ran the engine to be sure all was getting

oil (it's all slick inside).

Ignition: My engine has just a timer (10V DC is what I use) and the twin coil is

in the battery box. The real battery

is outside the engine because I use it to run several engines at shows. I run a

pair of wires from the battery into the box at the rear. There is a cut off switch

on the rear of the box.

That wire loom I made to hold the 5 wires away from the rotating pump and cam gear

parts. There are two

HV wires, one to each plug and three primary wires to the timer: one for each cylinder

and the center common.

My engine had three grease cups; one on each main. The literature and pictures we

have from the 1911 model shows 3 cups and states grease was available to "all

" bearings. This is really not true. I don't know for sure but I think my engine

was the first to run. Nobody could help me with any practical experience on running.

I just

did it by trial & error (at first I put a lot more oil in the crank wells and

saw that the engine just threw it out the back.) I ran my engine 6 hours at the

show in August and had no problems, no noises and the engine seems

fine. If you do uncover an operators manual I sure would appreciate a copy.! The

brass jackets on your engine are of real interest to me. Are they sheet brass? are

the a cast brass replica of what the cast iron jackets would look like?

Color of my engine is Ford model A heat resisting engine paint. One thing I error'd

on was in how I treated the heads and exhaust valve bodies. I knew my engine had

traces of a silver paint on the head and other "hot" (top)

areas but I ignored that clue. It's clear from the catalog illustrations on the

1916 engines that they appeared to use a single color paint over the whole engine. (Except one shot of a twin shows silver heads and exhaust)

Probably it was something like a black or dark blue high temperature paint. The

earlier 1911 catalog views show all the engines with a "silver" or lighter

color on all the heads and hot spots. There is no water cooling around the exhaust

valve cages and I should have realized that the engine paint (not made for the probably

400-500 degree temps there would burn off (which is what happened)

I would be sure to paint anything in the area of the heads and exhaust box etc.

with the 2000 degree stuff.

I think I mentioned already that I can send you a CD with all my pictures and scans

of catalogs if you could

use it. Just send me an address.

Let me know how it's going from time to time.

Tom Stranko |

thomas

Senior Member

Username: thomas

Post Number: 253

Registered: 07-2002

| | Posted on Thursday, March 10, 2005 - 06:45 pm: |

|

Bill,

I checked the Schebler on my Dunn and it has a 1"

pipe going into it. Any chance of some pictures

of your Dunn 3 cylinder??

Tom |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 726

Registered: 11-2001

| | Posted on Friday, March 11, 2005 - 09:46 am: |

|

1909 Dunn Special III

|

thomas

Senior Member

Username: thomas

Post Number: 254

Registered: 07-2002

| | Posted on Friday, March 11, 2005 - 10:02 am: |

|

Geeze!! That's what I want for Christmas.

Richard. Is there any mention of the

"special" in your catalogues?

Tom |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 727

Registered: 11-2001

| | Posted on Friday, March 11, 2005 - 12:37 pm: |

|

Tom

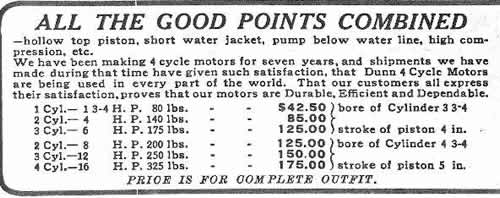

Have never seen any reference to this engine until Mike(Clockstopper) and Bill inquired about them on above posts ! So last night I dug into every reference source on Dunn That I have and found only two ads on consecutive months in 1909 !

-

Possible That SANTA might have two ?? |

andrew

Moderator

Username: andrew

Post Number: 1079

Registered: 11-2001

| | Posted on Saturday, March 12, 2005 - 10:35 am: |

|

This came in from Mike (Clockstopper):

quote:... As I have said, we are new at this technology stuff. I will do my best to get pics sent to you in the next few days .

Am I correct that there may be 1 other 3 cyl brass jug Dunn ?.

You guys are getting me reved up !. I do have a 16' mahogany planked boat from the 20's to put the DUNN into. Old stuffing box [ straight thru transom ] is about all I'm short. I'm still young, whats 1 more project ?.

Thanks again, Mike.

|

andrew

Moderator

Username: andrew

Post Number: 1080

Registered: 11-2001

| | Posted on Saturday, March 12, 2005 - 10:41 am: |

|

Tom sent in the following:

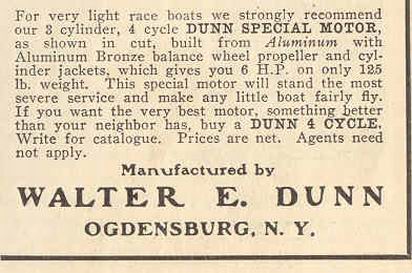

quote:...I'm attaching a 1909 Powerboating scan (from a Xerox) of a Dunn ad where they speak about making inboards since 1902 (according to my calculations).

It might be of interest to the Dunn crowd.

It's just a bit larger than the load limit.

Thanks

Tom

|

bill

New member

Username: bill

Post Number: 2

Registered: 03-2005

| | Posted on Sunday, March 13, 2005 - 07:07 pm: |

|

Thanks for all the replies. Bottom end is now at the machine shop to straighten bent crank and make a cam gear. Will post some pictures when I get it back

Bill |

andrew

Moderator

Username: andrew

Post Number: 1091

Registered: 11-2001

| | Posted on Sunday, March 13, 2005 - 08:32 pm: |

|

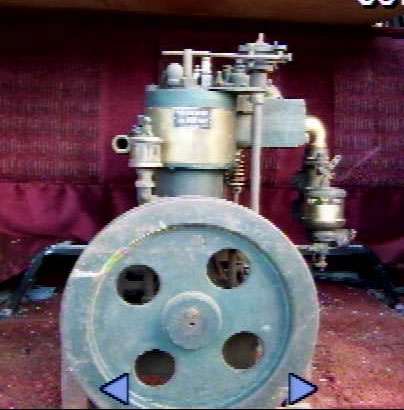

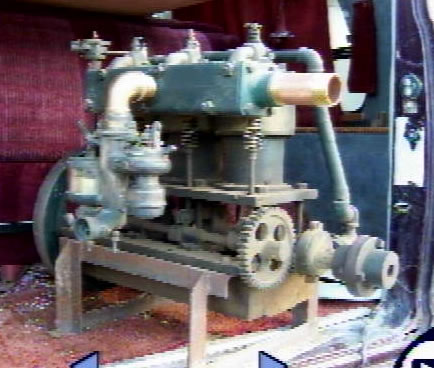

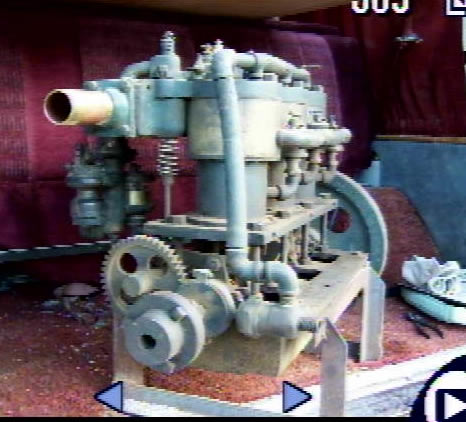

Here's what all the Dunn fans have been waiting for... pictures of Mike's (clockstopper) engine. The picture quality is not great... I cropped them and tried to make them better, but couldn't do much.

Thanks for sending them in Mike.

|

andrew

Moderator

Username: andrew

Post Number: 1092

Registered: 11-2001

| | Posted on Sunday, March 13, 2005 - 08:37 pm: |

|

Two more:

|

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 728

Registered: 11-2001

| | Posted on Sunday, March 13, 2005 - 10:53 pm: |

|

Mike, Big Thanks for the photos, That is quite a special old marine engine and looks original. Do you know if that is the original Paint and color ?

If so would you say its more of a Blue or a Green ??

Half the fun of these Old engs for me is to try to figure out what year they were made. The 1909 ad above mentions the brass jackets and I dont find any other references to them anywhere else as yet. The 1902 - 1915 Dunn muti's used a timer device driven from cam shaft at the rear of the engine. 1916 production came with the distributor type timer as on your eng. Also the water cooling plumbing changed a bit and was piped from the pump to top of the cylinder heads as opposed to the starboard side of the cylinder casting, so it seems that this engine would date 1916 or later ? Will keep you posted when any new info comes up ! Keep us posted as the project progresses . |

thomas

Senior Member

Username: thomas

Post Number: 255

Registered: 07-2002

| | Posted on Monday, March 14, 2005 - 10:46 am: |

|

Mike & Richard,

A great old engine!!

I would humbly point out that all the characteristics of this engine point to it being

1915 or newer. PROBABLY the Dunn Co made the racer all along but, maybe due to a limited demand, they didn't advertise it much and what Richard has from 1909 was possibly the first time it was offered??

Please keep us up to date as to progress.

T |

bob farwell

Visitor

| | Posted on Thursday, August 02, 2012 - 06:56 pm: |

|

hi i have 3 cyl brass dome. i do not know what it i s . boat i thank anny help would be nice bob cell 503-851-2337 |

Roger DiRuscio

Senior Member

Username: solarrog

Post Number: 520

Registered: 03-2002

| | Posted on Thursday, August 02, 2012 - 10:29 pm: |

|

Brass dome engine? or is this a part of one?

pictures would really help us |

Bruce Hall

Senior Member

Username: bruce

Post Number: 591

Registered: 07-2002

| | Posted on Monday, January 09, 2017 - 09:37 pm: |

|

Sounds possibly like a 3 cyl Pierce-Budd Brass Jacket engine?????.... |