|

| Author |

Message |

Tom Stranko

| | Posted on Saturday, October 25, 2003 - 04:30 pm: |

|

Had it shoved in my face today about "Haste makes waste" I was trying to hurry along my disassembly of the Dunn 2 cylinder so I could use the last of the warmth for outside painting.

I HAD to use the accetlyne torch to heat up the

intake valve castings because they screw on with a fine thread. The one came off ok. The other (that valve had been open and a mouse...)

just would not budge. I was using a big pipe wrench and a hammer. The last picture shows the casting and I think I can find someone to weld it back together |

Tom Stranko

| | Posted on Saturday, October 25, 2003 - 04:30 pm: |

|

|

Tom Stranko

| | Posted on Saturday, October 25, 2003 - 04:32 pm: |

|

|

Tom Stranko

| | Posted on Saturday, October 25, 2003 - 04:34 pm: |

|

|

richarddurgee

| | Posted on Sunday, October 26, 2003 - 12:30 am: |

|

Tom, Hope you can get a good weld on that casting

the pipe thread will want to push it apart!

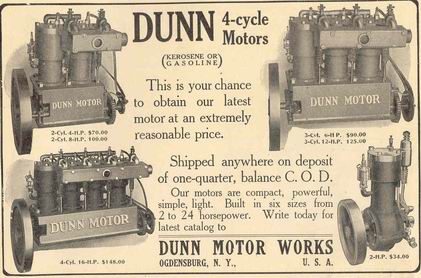

Have been researching Dunn and seems that up to 1913-14 the multi's had the gear driven timer on aft end of eng. By 1915 they had distributors, like ours.

1913 ad

Have a copy of a letter that was recieved by an eng collector from the son of Walter E. Dunn in 1985. The son also a Walter stated that his father

started with a single cyl eng in the late 1890's, and gradually added the others.He also went on to say that singles and twins were the most popular,and he did make 3, 4, 6, and on rare ocassions an 8 cylinder eng. The Co. ceased business in 1927 right after his fathers death, and the factory was dismantled in early 1930's.

He regrets that he did not have any engs or literature of the Co. |

Tom Stranko

| | Posted on Sunday, October 26, 2003 - 02:18 pm: |

|

Richard, I'm lucky about the pipe thread because this style intake uses the threaded casting from the single but does not actually have a threaded in pipe-just a push in. I'll probably have the guy just tack it in a few spots and use epoxy to

smooth it out/

Tom |

|

|

|

|