| Author |

Message |

andrew

| | Posted on Friday, January 10, 2003 - 10:05 am: |

|

Larry Healy sent in the following:

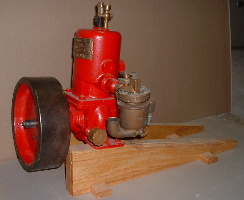

Quote:I'm sending you some photos of a little Midland engine I restored for static display. The flywheel on this engine is about 10"--maybe one H.P.?

-- Many thanks for your great site & have a great New Year!

Larry Healey Campbellford,Ont.

|

Ernie

| | Posted on Friday, January 10, 2003 - 01:52 pm: |

|

Wow another userer of the Detroit Auto Marine castings. I wonder what it had for a timer? |

mechman

| | Posted on Saturday, January 11, 2003 - 02:03 pm: |

|

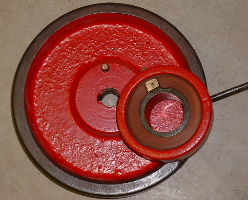

Goodday all. Here are a couple of photos of the timer--very simple mechanism--red rubber insulation mounted between an inner & outer circle which in turn is mounted on a boss extention over the crankshaft this has the timing contact mounted in it,a long set screw bolt is tightened or loosened to control timing & there is a brass spring loaded contact in the flywheel which grounds the coil at the set time.   |

Ernie

| | Posted on Sunday, January 12, 2003 - 09:42 am: |

|

Larry,

Thanks for the additional pics. Your engine has a timer like the Ferro Auto Marine used. I think the Cady version of this engine also used this style. Most of the Detroit Auto Marine and Little Major versions used rotary timers mounted on the upper forward face of the cylinder and driven by bevel gears from the front of the crankshaft |

richarddurgee

| | Posted on Sunday, January 12, 2003 - 05:35 pm: |

|

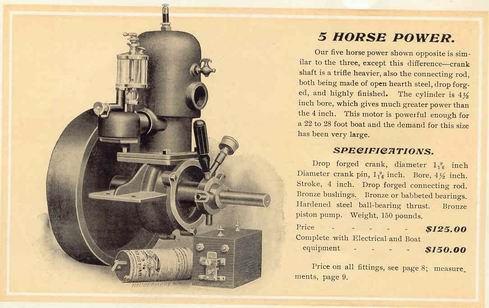

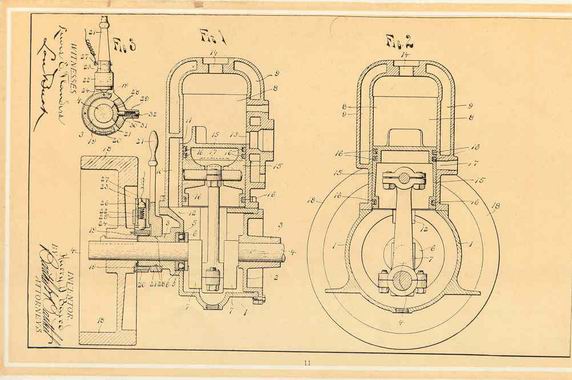

From a 1906 catalog!

|

richarddurgee

| | Posted on Sunday, January 12, 2003 - 05:49 pm: |

|

Same catalog as above, but illustration of a different timer ?

|

miro

| | Posted on Sunday, January 12, 2003 - 06:48 pm: |

|

Neat to see the drawing of the inventor. I wonder if they ever DID build one like the drawing, because if you look closely ( I used a magnifing glass on my computer screen) they put the thrust bearing at the flywheel end. That crank must have been stout to take the thrust and not fail due to fatigue bending.

miro

( ahhh - yes . .. I also know how to count the number of angels that dance on heads of pins) |

Ernie

| | Posted on Sunday, January 12, 2003 - 07:01 pm: |

|

Yes they did put the thrust bearing on the forward end of the crank. I have had several of these apart. The little one from above is 1.5 hp. Richards ad is for the big one. Lots of the little ones around. I have only seen 1, 5hp engine. All of the little ones seem to have the mount on the base as in Richards add above no matter what year they were. So far I have seen or read about this style engine with the following names.

(Maybe more these are from memory)

Detroit Auto Marine I currently own one

Little Major Ross Gould owns one

Ferro Auto Marine Jimmie Whidbee owns one

Cady

Atlantic One on it's way to my shop

Midland

Also Little Giant and Strielinger were involved. There is some print info I think in one of G. Boley's books to link them together. |

Richard Day

| | Posted on Sunday, January 12, 2003 - 08:03 pm: |

|

The Belle Isle had the same thrust bearing set up. I doubt the amount of thrust on the crank from the prop was signicant compared to the area of the crank. |

richarddurgee

| | Posted on Sunday, January 12, 2003 - 08:14 pm: |

|

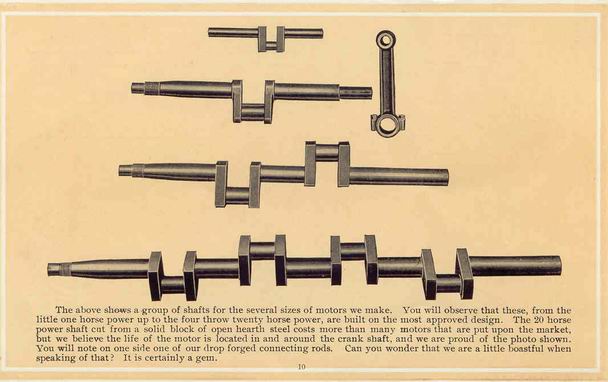

Miro:

Seems that Detroit auto was proud of their crankshafts. Except for the little one all were

tapered and threaded (1906).

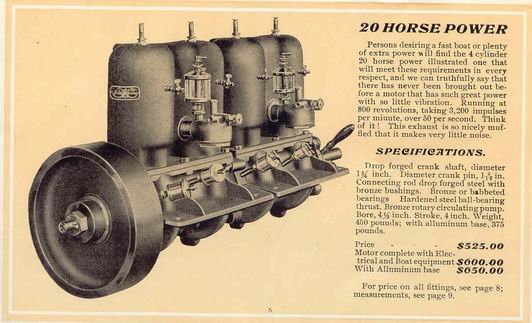

Here's the 20 Hp engine that goes with the big crank.

|