| Author |

Message |

bgoss

Advanced Member

Username: bgoss

Post Number: 34

Registered: 12-2007

| | Posted on Monday, August 25, 2008 - 07:54 pm: |

|

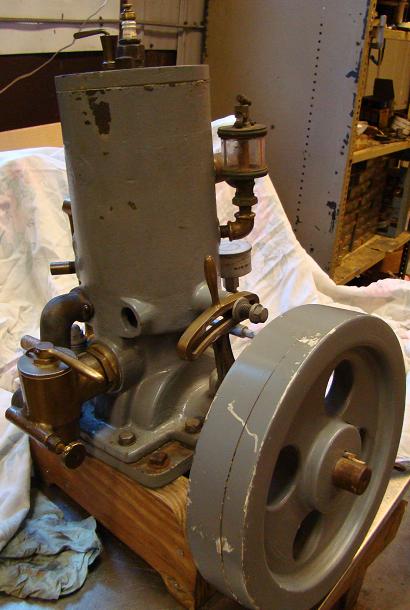

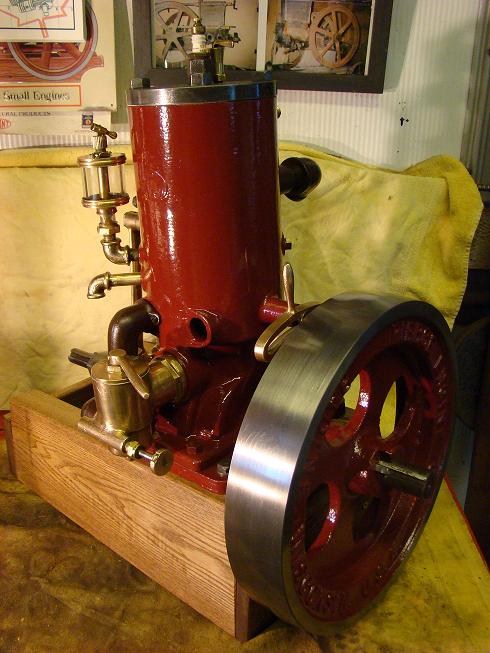

We just picked this little gem up at Portland last week. JB was around and was able to help identify it as a Pierce (ignore the flywheel as it is a wooden pattern).

I did a search through the site here and can't find anything just like it. Many of the Pierce engines have a blind/dome head. Keith's Racine engine is much different again with the piston trip mechanism.

Any help with other photos/literature would be appreciated. Any ideas on age? Would it have had the Pierce flywheel with raised letters?

Thanks. Blair

|

john_archibald

Senior Member

Username: john_archibald

Post Number: 78

Registered: 08-2006

| | Posted on Monday, August 25, 2008 - 07:59 pm: |

|

Blair,

What a little gem!

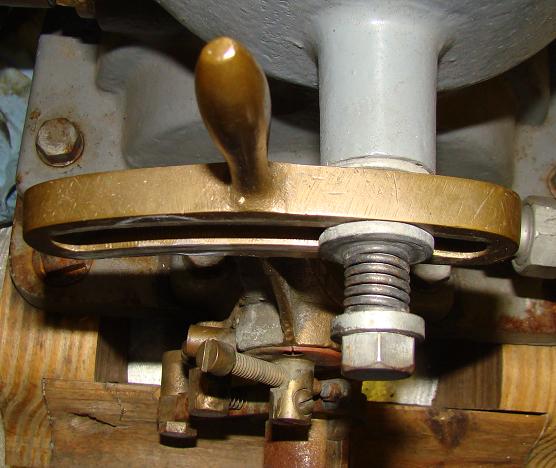

I suppose the bronze arm with the arc is an ignition timing device, perhaps giving reverse???

Regards,

Archibald

Northfield, Minnesota

. |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 387

Registered: 07-2002

| | Posted on Monday, August 25, 2008 - 08:49 pm: |

|

Blair, the PIERCE is cast into the flywheel, if you have someone to cast it you can use mine as a pattern. We don't have anyone doing cast iron around here, the flywheel ads to the looks of the engine. Go to this post,

http://www.oldmarineengine.com/discus/messages/3428/104458.html

about halfway down you will see Dickie Gibbens Peirce, it's a larger engine but the flywheel is similar. |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1783

Registered: 11-2001

| | Posted on Monday, August 25, 2008 - 09:49 pm: |

|

*

Cool old marine Engine and the only one of these I've seen with the original cast warm air intake manifold !

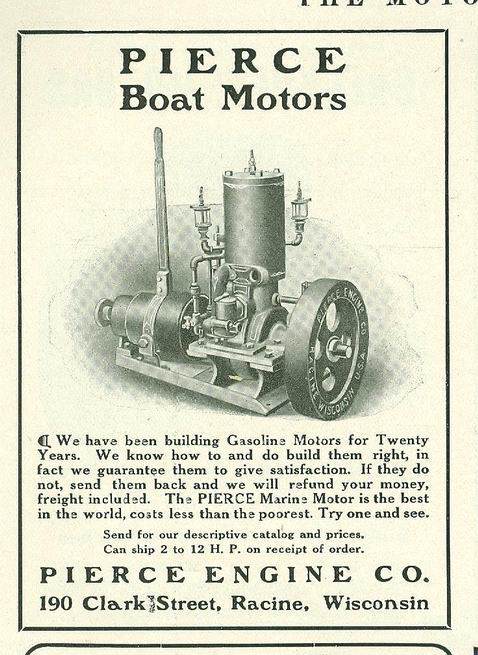

Pierce was one of the older marine engine mfgrs and their designs changed with the advance of technical knowlege, the engines with the removable heads were older than the headless ones. As a rule of thumb I use the year 1906 as a general reference point. yours in above posts is approx 1904-05- this is a 1905 ad.

1905

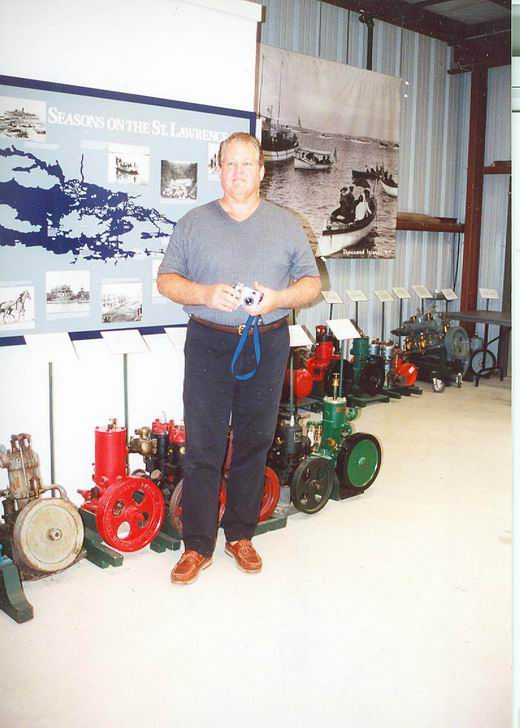

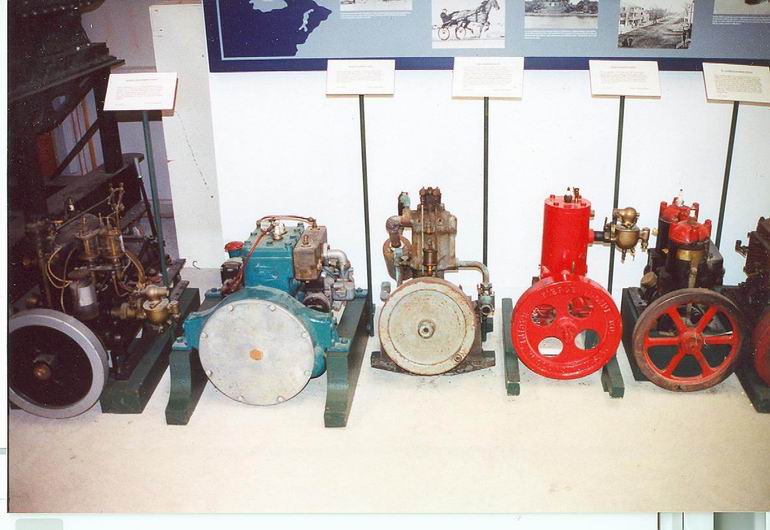

This is a similar engine in the Clayton Boat museum in Clayton, New York, I took this photo in 2002 and have always remembered it because It must have been extremly hard to start with the carburetor screwed into the exhaust port ??

This is "Yours Truly" but the only shot that shows the intake side- also some of the surounding engines !

A few more of the engs!

* |

miro

Senior Member

Username: miro

Post Number: 339

Registered: 11-2001

| | Posted on Tuesday, August 26, 2008 - 10:24 am: |

|

Blair, there is a Menonite foundry that does cast iron in Floradale north of Elmira.

If you have a pattern they'll give it a try.

Priced usually per pound of cast iron.

Dodington and i visited and had them cast some smaller parts.

Their main line of business is cast iron parts for wood burning stoves and ovens. The place is great - just like an old foundry. But they are good - they Blanchard grind their stove tops.

miro |

bgoss

Advanced Member

Username: bgoss

Post Number: 36

Registered: 12-2007

| | Posted on Tuesday, August 26, 2008 - 09:13 pm: |

|

Wow. That's a great help. The guys on here never cease to amaze.

Archibald - You're correct, the brass quadrant on the front is for advance and retard. But rather than just a contact on a fibre at it's base, it has a set of points that runs off an eccentric on the crank.

JB - Thanks for the offer of the pattern. We'll likely take you up on that to make the engine complete. I'll be in touch. The Mystic07 thread killed my dial-up, but I did make it down to the Pierce.

Richard - Thanks for posting that ad. It answered another question that I was going to ask about the two holes into the cylinder near the bottom of the stroke. We had two oilers installed, one on each side, and thought that it looked like overkill...I guess we'll put the second one back in.

The intake air warmer goes all the way around the cylinder before traveling through that little cast trunk and into the carb.

Miro - Thanks, I believe that is the foundry that we have used for a larger stationary flywheel in the past. Lately we've been making more trips to the brass, bronze and aluminum foundry for small stuff.

Is there a chance that the greaser plumbing for the main bearings is correct? Someone did a real nice job of matching old fittings if it is a retrofit. |

scott_n

Advanced Member

Username: scott_n

Post Number: 43

Registered: 02-2008

| | Posted on Wednesday, August 27, 2008 - 08:51 am: |

|

The grease cup was probably set up like that to make it easier to serves in the boat. Nice engine the intake warmer is very interesting |

richarddurgee

Senior Member

Username: richarddurgee

Post Number: 1786

Registered: 11-2001

| | Posted on Wednesday, August 27, 2008 - 09:49 am: |

|

*

This is a photo of J.B.'s flywheel

* |

bgoss

Advanced Member

Username: bgoss

Post Number: 37

Registered: 12-2007

| | Posted on Saturday, August 30, 2008 - 09:22 pm: |

|

Thanks guys. |

bgoss

Senior Member

Username: bgoss

Post Number: 137

Registered: 12-2007

| | Posted on Sunday, January 17, 2010 - 03:29 pm: |

|

Thanks to all who contributed to getting this Pierce back in shape. That flywheel logged a lot of miles.

.

.

Thanks again, Blair |

jb_castagnos

Senior Member

Username: jb_castagnos

Post Number: 499

Registered: 07-2002

| | Posted on Sunday, January 17, 2010 - 08:26 pm: |

|

Looks good Bruce, glad you got it done. |

robert

Senior Member

Username: robert

Post Number: 332

Registered: 07-2003

| | Posted on Monday, January 18, 2010 - 02:43 am: |

|

Beautiful job! BTW, Can I ask what the maple leaf motif is in the upper left corner (on the wall)? |

ernie

Senior Member

Username: ernie

Post Number: 1149

Registered: 01-2002

| | Posted on Monday, January 18, 2010 - 07:51 am: |

|

Nice!

A word of caution on one grease cup feeding 2 bearings. You have to continously monitor BOTH bearings to make sure they are getting grease because if one plugs up the grease cup still works and you won't know one is running dry |

robert

Senior Member

Username: robert

Post Number: 333

Registered: 07-2003

| | Posted on Monday, January 18, 2010 - 10:34 am: |

|

I'm wondering how that gibb key and starting crank meshed safely (I assume this engine came with a crank from the cogs on the front of the flywheel boss?) |

bgoss

Senior Member

Username: bgoss

Post Number: 138

Registered: 12-2007

| | Posted on Tuesday, January 19, 2010 - 05:34 pm: |

|

Robert - The maple leaf that you noticed is on a JD Two-cylinder Club calendar. You're right about the gibb key. If you were planning on starting with a crank, the key would have to be set in further. I see on JB's flywheel that there is a knotch cut into the ramp on the hub. That would allow you to bury the gibb key head.

It would also make for a real mess trying to get the key back out if you had to...

Do you think that they actually ran these with the two oilers shown in Richard's ad above? Or is this just another example of artists expression to show that the engine could be set up to operate from either side depending on your application? |

robert

Senior Member

Username: robert

Post Number: 335

Registered: 07-2003

| | Posted on Tuesday, January 19, 2010 - 05:44 pm: |

|

Blair, thanks. My guess would be yes, on the oilers. Makes sense really to half the time required for the oil to migrate around the piston and rings, as well as feeding the wrist pin(?) from both sides. It shows a desire to build for durability rather than cost IMO. I noticed some photos of a large marine engine the other day that had four oil ports equidistant around the cylinder walls, fed by a force feed lubricator. |