|

| Electronic ignition for 2-cycle engines |

| Author |

Message |

Barry Millar

Member

Username: barry

Post Number: 15

Registered: 02-2006

| | Posted on Friday, September 08, 2006 - 04:27 pm: |

|

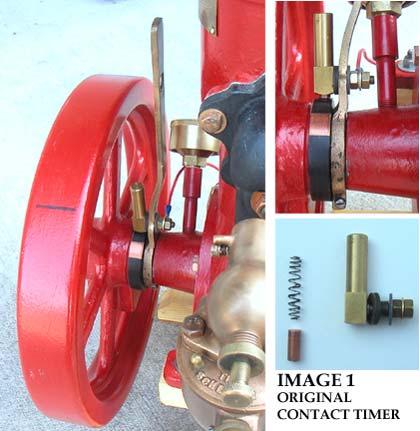

An old single cylinder 2-cycle engine powers my boat. The original timer is the type that uses a copper slug and fiber ring mounted behind the flywheel in combination with a spring loaded copper pawl that rides on the ring to provide an electrical path to ground for a buzz coil. Image 1 illustrates this arrangement.

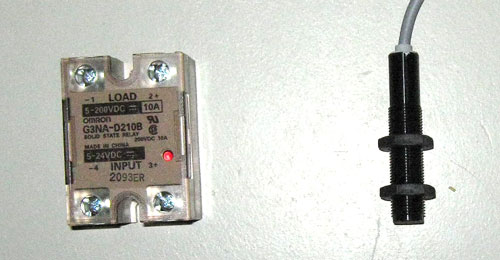

I modified this to make to use a non-contact electronic sensor in place of the spring-loaded pawl. The sensor is positioned above the fiber ring about .03 inches. The sensor reacts to the copper slug and turns on a power transistor. The transistor (10 amp rating) provides an electrical path to ground for the buzz coil. Image 2 illustrates this arrangement.

Using the original contact arrangement, the path to ground is tortuous and in my experience becomes unreliable as an engine wears. Grease from the main front bearing deposits on the fiber ring, and elsewhere. This blocks current flow, resulting in engine misfiring. Sometimes the grease build -up causes an engine to stop without warning, always at the least opportune moment.

On the other hand, the electronic sensor is unaffected by grease or component wear. I have been using the electronic timer for several boating seasons with 100% reliability. Several “Dippy” owners are using it with the same success. The sensor is very common for Industrial automation use and is readily available in many sizes and styles. It is an inductive device requiring a 12-volt supply, and is therefore suitable for use with a hand start engine. The transistor is available in a convenient package and sold as a solid-state relay also used for Industrial automation.

An automotive coil can be used in place of a buzz coil to provide a one shot spark. Timing changes by about 45 degrees. Using a buzz coil, ignition in initiated when the leading edge of the copper slug is sensed, whereas using an automotive coil for one shot ignition, the spark occurs when the trailing edge is sensed. A small screw inserted in the fiber ring to act as a target for the sensor overcomes this problem. Image 3 illustrates the set-up.

I am sure other timer styles can be similarly converted. I am using my test bench to validate a sensor for use at 6 volts. I will be pleased to post details if there is any interest.

Barry

|

Barry Millar

Senior Member

Username: barry

Post Number: 89

Registered: 02-2006

| | Posted on Saturday, November 15, 2008 - 03:06 pm: |

|

Here is an image of an electronic timer installed on a 1.5HP 1910 McKEOUGH & TROTTER two stroke.

|

William Schaller

Senior Member

Username: billschaller

Post Number: 178

Registered: 12-2003

| | Posted on Saturday, November 15, 2008 - 06:41 pm: |

|

I would be interested in knowing what parts would work for this. I plan on making a very slow running twin flywheel lauson air cooled some day. |

Barry Millar

Senior Member

Username: barry

Post Number: 90

Registered: 02-2006

| | Posted on Sunday, November 16, 2008 - 10:39 am: |

|

Bill,

We have standardized on an inductive sensor that will work from 5 or 30 volts. Several Dispro owners have changed to the electronic timer with excellent result as many were experiencing erratic operation due to grease and component wear.

They all use buzz coils, some at 6 volts, some at 9 volts, some at 12 volts, thus this a “fits all voltage” sensor.

Let me know via email if you need a 6 volt sensor as these are not commercially available. We have a special arrangement with the supplier for the 5 -30 volt unit. There are many commercially available for 12 volts from an industrial distributor, Baumer IFRM 12N1702L for example.

Spec is

Inductive proximity sensor, 12 mm cylindrical, 3 wire, 4mm sensing range, normally open, NPN output, shielded, 12 volt DC supply, cable connection.

The solid state relay is an Omron part G3NA-D210B.

ok for 5 - 24 volts DC.

If you need a circuit, let me know.

Barry

|

|

|

|

|